A prefabricated panel turning device

The technology of a turning device and a prefabricated plate is applied in the field of industrial manufacturing, which can solve the problems of no assembly line production, insufficient turning over, and overturning, etc., and achieve the effect of facilitating assembly line production and increasing the load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

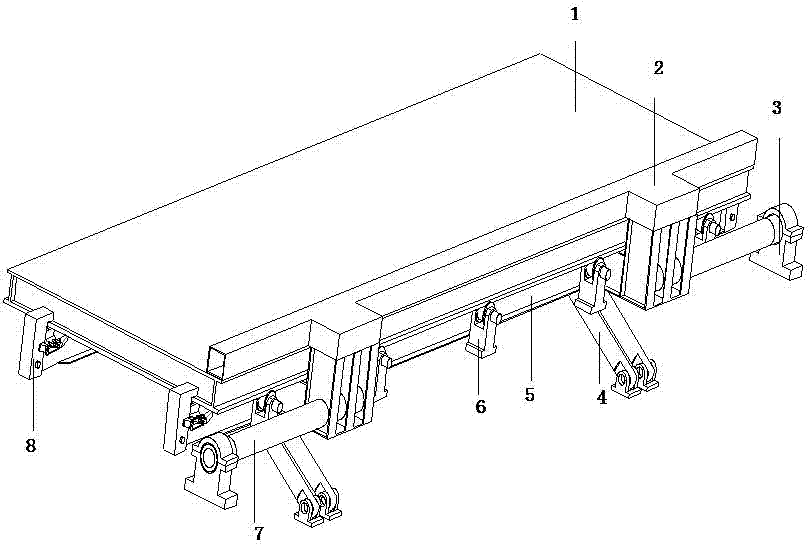

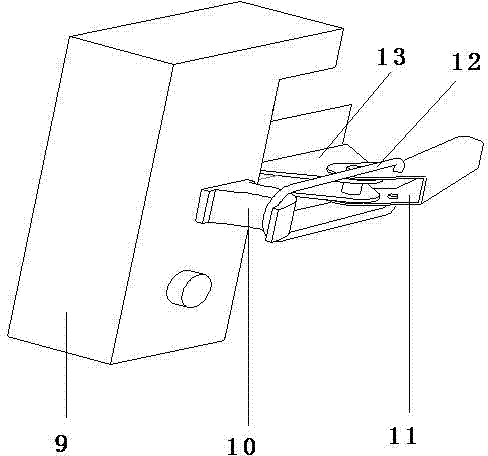

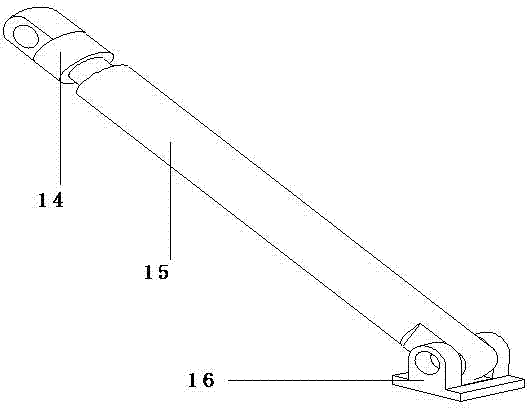

[0014] A prefabricated panel turnover device provided by the present invention is used for overturning and transporting the prefabricated panels after they are manufactured, such as figure 1 As shown, the device of the present invention includes a prefabricated beam 1, a pressing plate 2, a hinge frame 3, an oil cylinder device 4, an overturning frame 5, a driven support device 6, a rotary shaft 7 and fixing devices 8 at both ends. The driven support devices 6 are distributed on the left and right sides of the overturn frame 5, and are used to support the left and right side edges of the prefabricated beam 1. Five identical driven support devices 6 are evenly arranged on the left and right sides of the overturn frame 5 respectively. The supporting device 6 is fixed on the ground. One end of the oil cylinder device 4 is hinged on the flip frame 5, and the other end is fixed on a plane lower than the installation surface of the flip frame by a certain distance through the oil cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com