Pneumatic cigarette pack beveling machine

A pneumatic and cigarette label technology, which is applied in the field of pneumatic angle bending machine to bend the right angle on cigarette labels in batches, can solve the problems of increasing the labor intensity of charter planes or quality inspection personnel and reducing production efficiency, so as to improve the adaptability of charter planes and improve Production efficiency and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

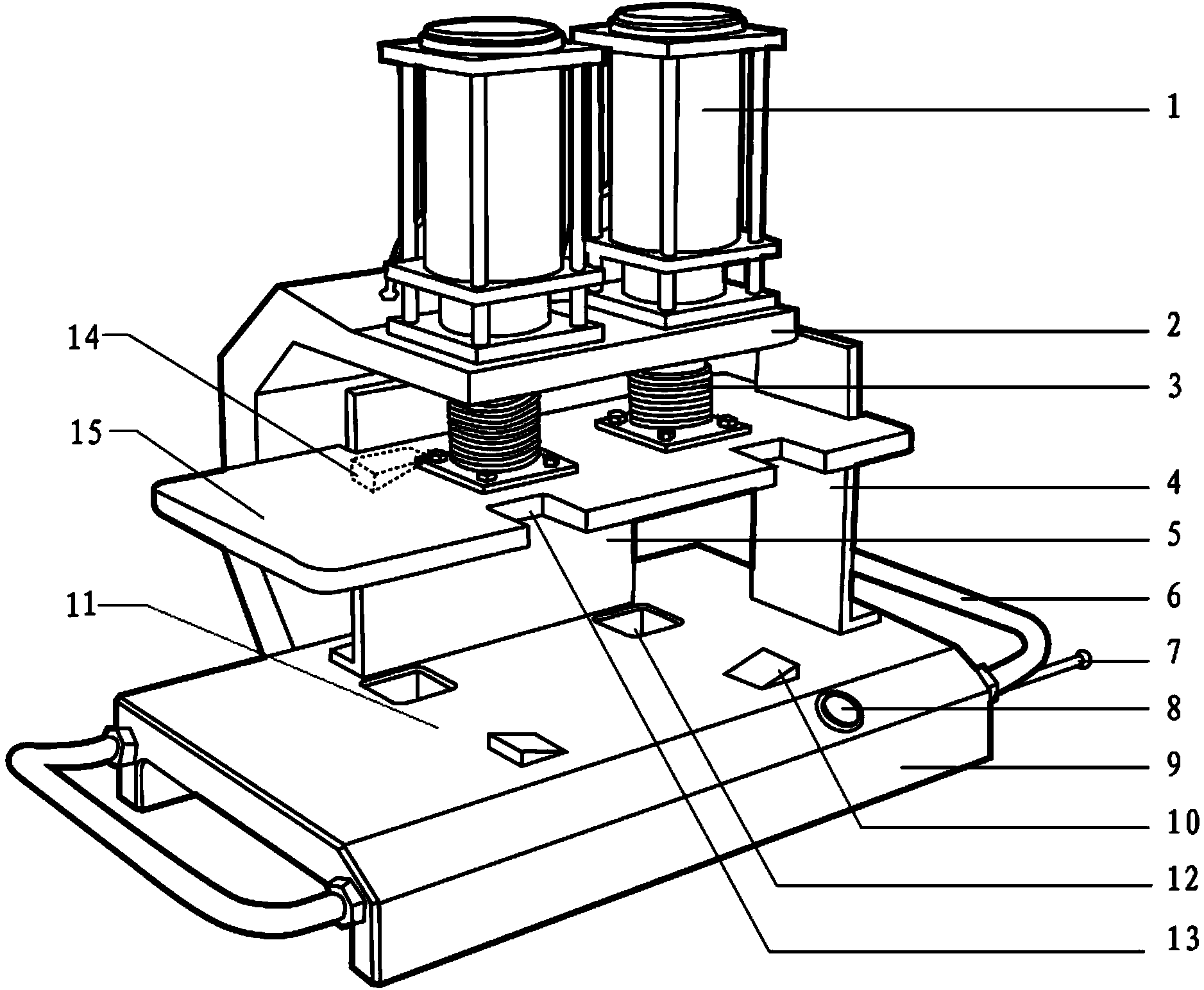

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] The structure of the pneumatic cigarette label cornering machine provided by the invention is as follows: figure 1 As shown, the upper surface of the base 9 is a workbench 11, the support frame 2 is fixedly connected with the base 9, and the left and right ends of the base 9 are provided with a C-shaped mobile steel frame 6. Compression cylinder 1 is installed downwards on the support frame 2, and is provided with two, and its telescoping rod faces workbench 11, and the interface 7 on the air pipe of described compression air cylinder 1 is fixed on one end of base 9, and also on the air pipe An air pressure button 8 for controlling the air pressure is provided, and the air pressure button 8 is installed on the base 9 .

[0025] The upper pressing plate 15 is fixedly mounted on the bottom of the telescopic rod and is parallel to the workbench 11. The said tele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap