A movable lifting device and its construction and installation method

The technology of a lifting device and an installation method is applied in the directions of transportation, packaging, and load hanging components, etc., which can solve the problems of wasting hoisting materials and high hoisting costs, and achieve the effects of cost saving, simple structure, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

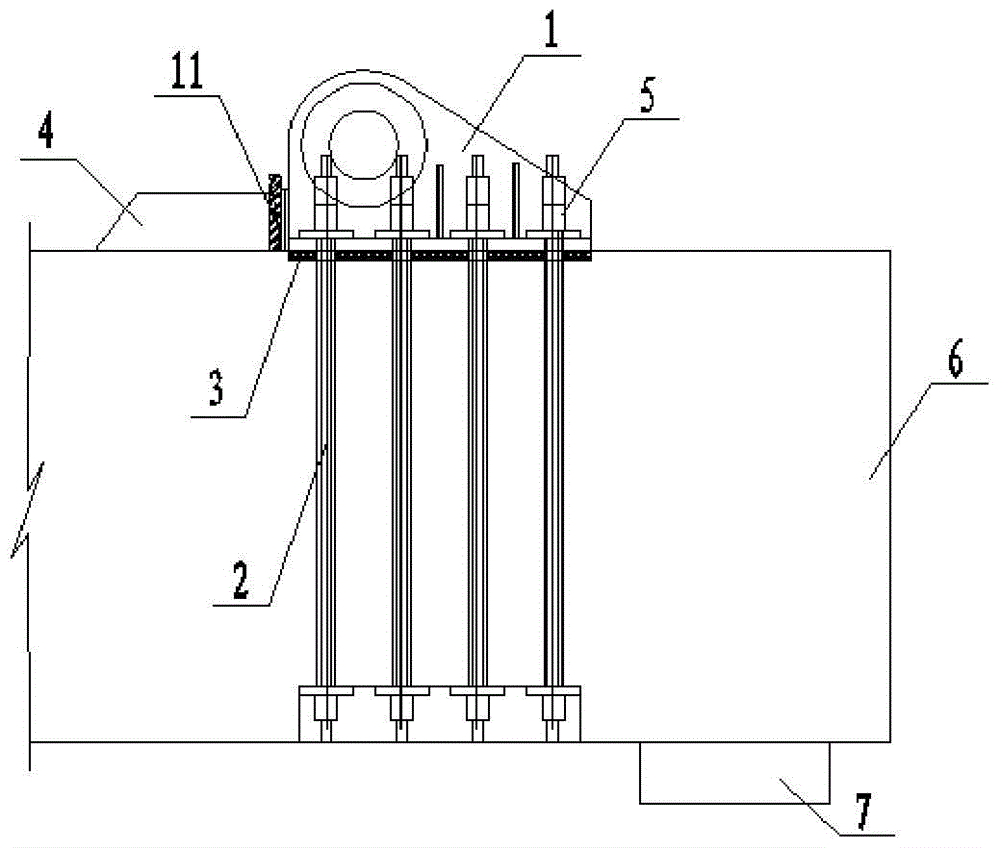

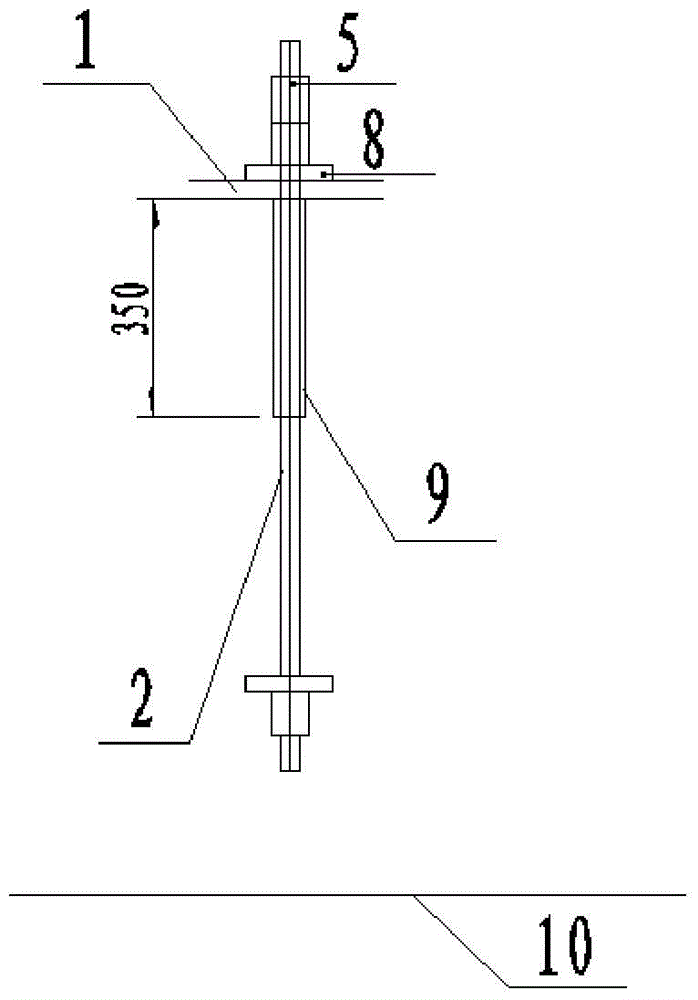

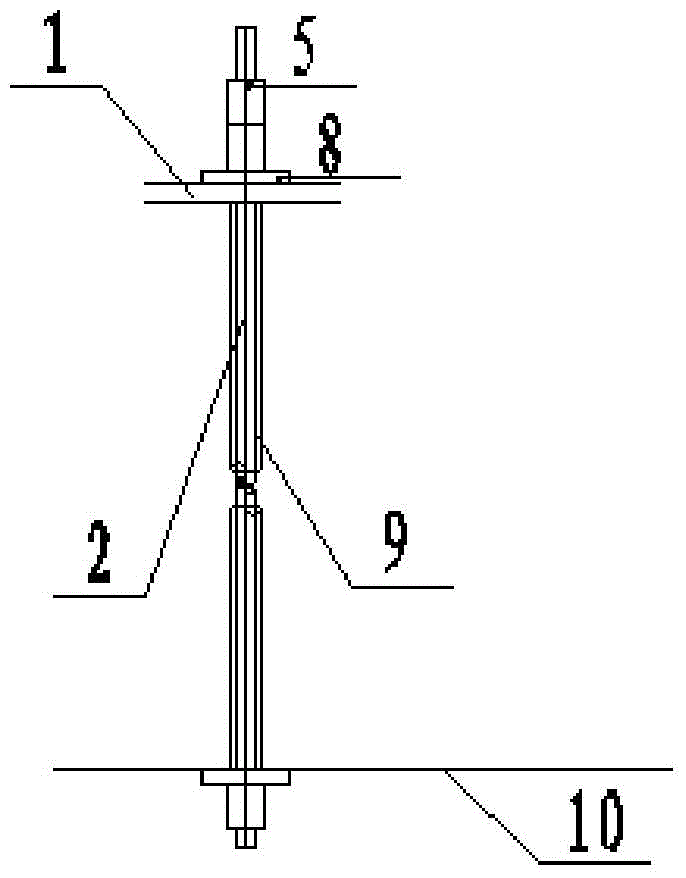

[0035] see figure 1 , figure 2 and image 3 , a new type of movable lifting device, including a lifting lug 1, the lifting lug 1 is connected with a screw rod 2 through a nut 5, a supporting member 4 is arranged on the side of the lifting lug 1, and a concrete prefabricated part 6 is arranged at the bottom of the lifting lug 1.

[0036] A steel backing plate 8 is set between the nut 5 and the lifting lug 1; the screw 2 is set in the concrete prefabricated part 6 through the reserved hole sleeve 9, and the positioning part 3 can be set between the bottom of the lifting lug 1 and the concrete prefabricated part 6, mainly For accurate positioning of the screw 2, the positioning part 3 adopts a steel plate structure, and holes are reserved according to the position of the screw 2, and the lifting lug 1 can be reused after being removed; Prefabricated, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com