Glass-ceramic plate for industrial protection and preparation method thereof

A technology of glass ceramics and industrial protection, which is applied in the field of glass ceramic plates and its preparation, can solve the problems that the performance of glass-ceramic materials is not enough for industrial protection, and the composition of the microcrystalline phase of the basic glass system has not been informed, so as to ensure Product quality stability, the effect of realizing industrial scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

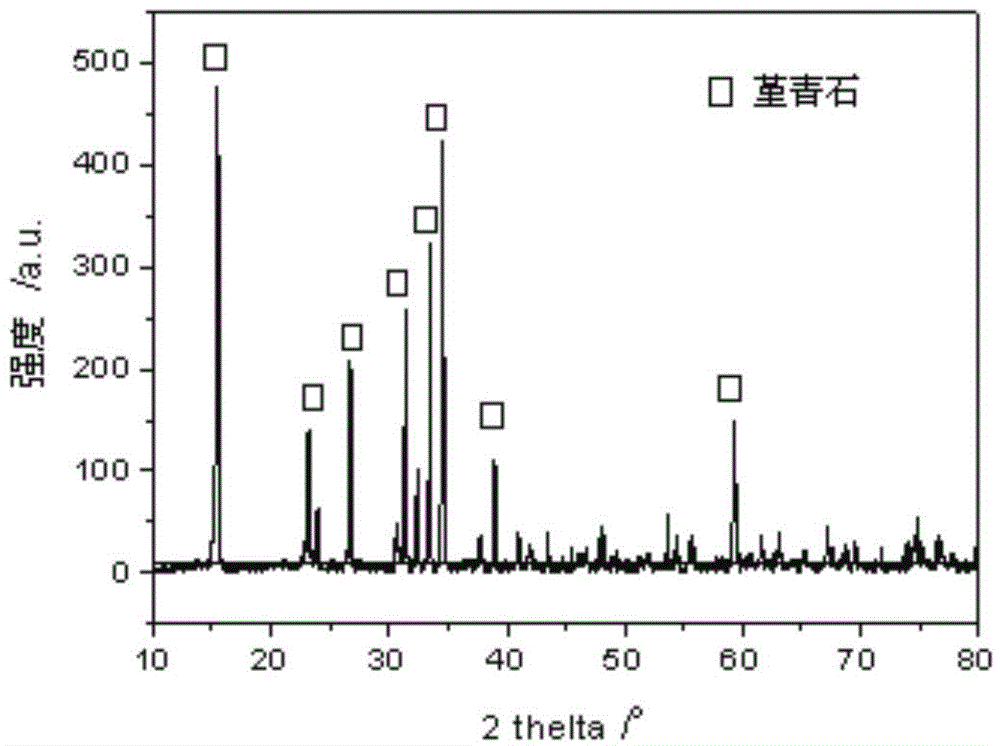

Image

Examples

Embodiment 1

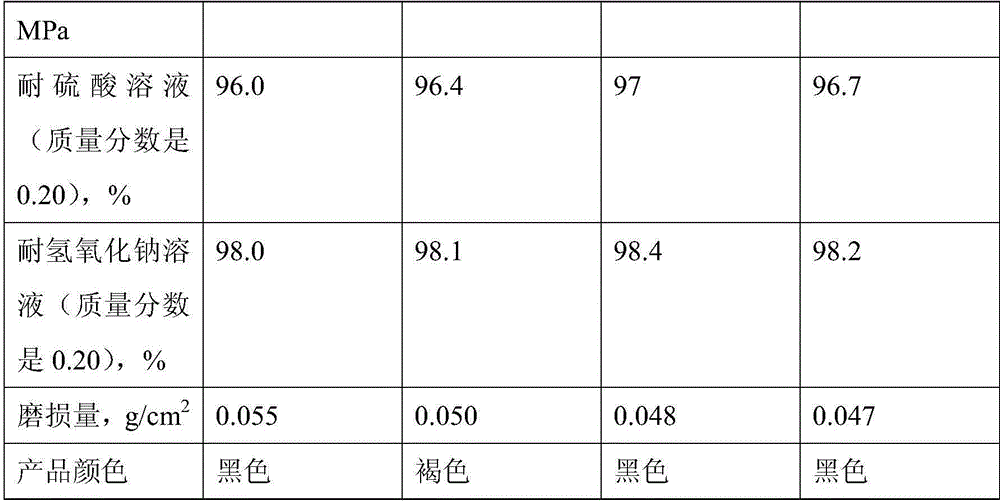

[0045] Embodiment 1, a kind of preparation method of industrial protective glass-ceramic plate, carries out following steps successively:

[0046] 1), according to CaO-MgO-Al 2 o 3 -SiO 2 System requirements (matching of raw material components during batching), so that the basic compound components in the raw materials reach the following weight percentages:

[0047] SiO 2 55%, MgO8%, CaO13%, Al 2 o 3 8%, FeO3%, Na 2 O+K 2 O3% (ie, Na 2 O is 0.5%, K 2 O is 2.5%), CaF 2 7%, TiO 2 3%.

[0048] Choose about 40 parts of iron tailings, about 5 parts of dolomite, about 40 parts of quartz sand, about 5 parts of potassium feldspar, about 7 parts of fluorite, and about 3 parts of titanium dioxide as raw materials, so as to ensure the The composition of the compound satisfies the above weight percentage.

[0049] 2) Fully mix the raw materials evenly, place them in a glass melting furnace and heat them to 1480-1500°C for 3 hours, put them into a clarification tank at 1500-...

Embodiment 2

[0053] Embodiment 2, a kind of preparation method of industrial protective glass-ceramic plate, carries out following steps successively:

[0054] 1), according to CaO-MgO-Al 2 o 3 -SiO 2 System requirements (matching of raw material components during batching), so that the basic compound components in the raw materials reach the following weight percentages:

[0055] SiO 2 52%, MgO8%, CaO12%, Al 2 o 3 10%, FeO5%, Na 2 O+K 2 O4% (i.e. Na 2 O is 1%, K 2 O is 3%), CaF 2 6%, TiO 2 3%.

[0056] Choose about 50 parts of iron tailings, about 5 parts of dolomite, about 30 parts of quartz sand, about 5 parts of potassium feldspar, about 7 parts of fluorite, and about 3 parts of titanium dioxide as raw materials, so as to ensure the The composition of the compound satisfies the above weight percentage.

[0057] 2) Fully mix the raw materials evenly, heat them in a glass melting furnace to 1480-1500°C for 3 hours, put them into a clarification tank at 1500-1550°C for 2 hour...

Embodiment 3

[0061] Embodiment 3, a kind of preparation method of industrial protective glass-ceramic plate, carries out following steps successively:

[0062] 1), according to CaO-MgO-Al 2 o 3 -SiO 2 System requirements (matching of raw material components during batching), so that the basic compound components in the raw materials reach the following weight percentages:

[0063] SiO 2 50%, MgO10%, CaO14%, Al 2 o 3 8%, FeO3%, Na 2 O+K 2 O4% (i.e. Na 2 O is 0.5%, K 2 O is 3.5%), CaF 2 8%, TiO 2 3%.

[0064] About 40 parts of iron tailings, about 10 parts of dolomite, about 31 parts of quartz sand, about 8 parts of potassium feldspar, about 8 parts of fluorite, and about 3 parts of titanium dioxide are used as raw materials to ensure the The composition of the compound satisfies the above weight percentage.

[0065] 2) Fully mix the raw materials evenly, heat them in a glass melting furnace to 1480-1500°C for 3 hours, put them into a clarification tank at 1500-1550°C for 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com