Method for producing naphtha, diesel oil and lubricant base oil by using used lubrication oil

A technology for lubricating base oil and waste lubricating oil, which is applied in the directions of lubricating composition, petroleum industry, processing hydrocarbon oil, etc. Production interruptions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

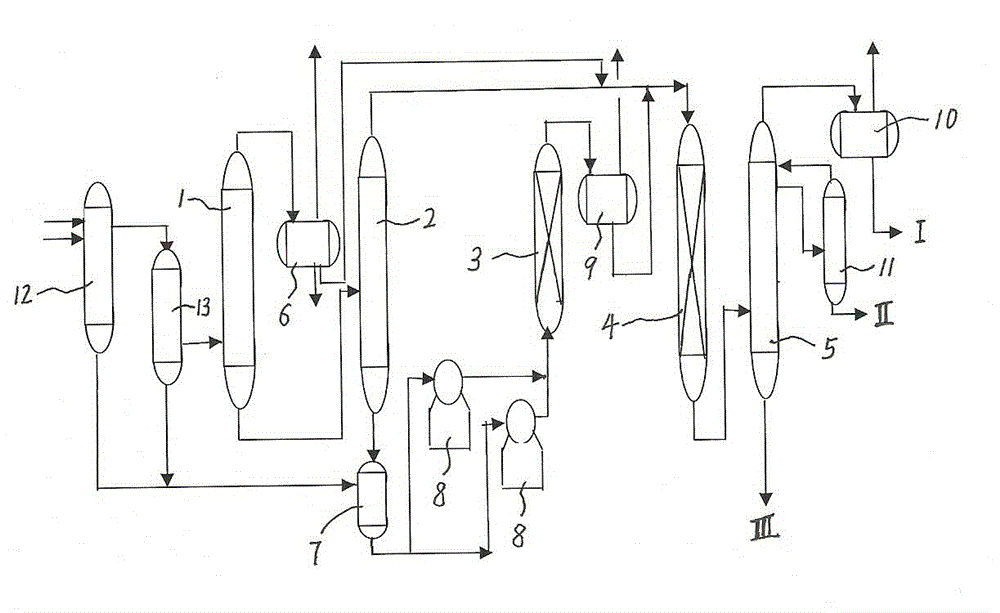

[0009] see figure 1 , a method for producing naphtha, diesel oil and lubricating oil base oil from waste lubricating oil of the present invention, comprising the step of distilling waste lubricating oil in an atmospheric distillation tower, the fraction at the top of the tower being less than 200°C enters an oil-gas separation tank for separation, and the oil and gas The liquid phase separated in the separation tank enters the hydrogenation reactor for hydrogenation and refining, and the bottom part enters the vacuum distillation tower for distillation; the vacuum degree in the vacuum distillation tower is maintained at 95-100KPa, and the vacuum distillation tower is less than The fraction at 500°C enters the hydrogenation reactor from the top of the tower for hydrorefining, and the fraction above 500°C enters the cracking raw material tank from the bottom of the tower for cracking; The fraction after distillation enters the oil-gas separation tank for separation, and the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com