Construction method of spiral cone extruded soil pile

A construction method and a technology of soil-squeezing piles, which are applied in the fields of earth drilling, sheet pile walls, and foundation structure engineering, can solve problems such as the inability to apply hard ground, reduce the bearing capacity of piles, and form false screw teeth, etc., to achieve pile formation The quality is controllable and reliable, the pile bearing capacity is high, and the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Construction Method of Spiral Cone Squeeze Pile

[0030] (1) Spiral Cone Soil Squeeze Bit

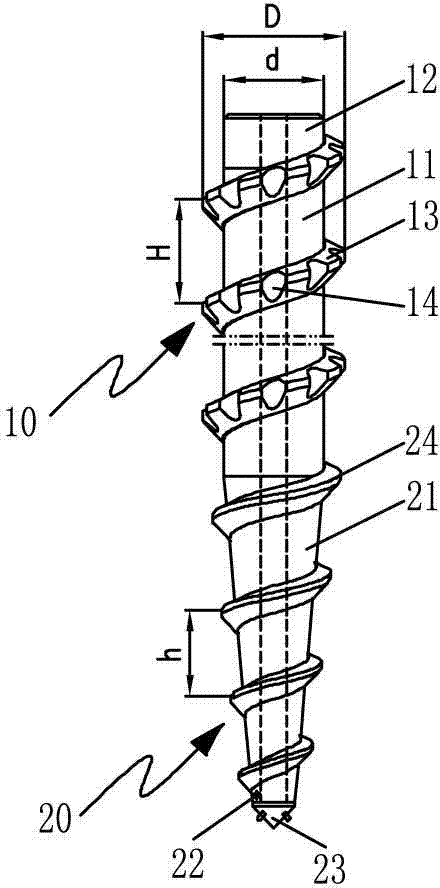

[0031] Such as figure 1 As shown, the spiral cone soil-extruding drill bit is composed of a spiral cylinder structure (10) and a spiral cone structure (20) to form an integrated structure.

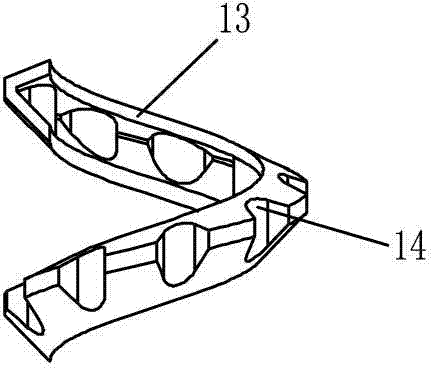

[0032] The spiral cylinder structure (10) is: a drill joint (12) is provided at one end of the cylinder core tube (11), and a spiral cylinder blade (13) is provided on the outer edge of the cylinder core tube (11). Such as Figure 2-3 As shown, several notches (14) are evenly provided on the helical cylinder blade (13). Such as Figure 6 As shown, the cross-section of the helical cylinder blade (13) is quadrilateral, and the included angles between the two sides and the cylinder core tube (11) are φ=45-50° and ω=65-70° respectively. Spiral cylinder blade (13) is the blade of equal height. The distance H=350~420mm between the helical cylinder blades (13). The diameter D of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com