Method and device for detecting glass bent through baking

A detection method and technology of detection devices, which are applied to measurement devices, optical devices, instruments, etc., can solve the problems of not being able to understand product quality in time, measurement timeliness and accuracy errors, and poor rhythm control, so as to achieve online The effect of automatic detection, improving detection efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

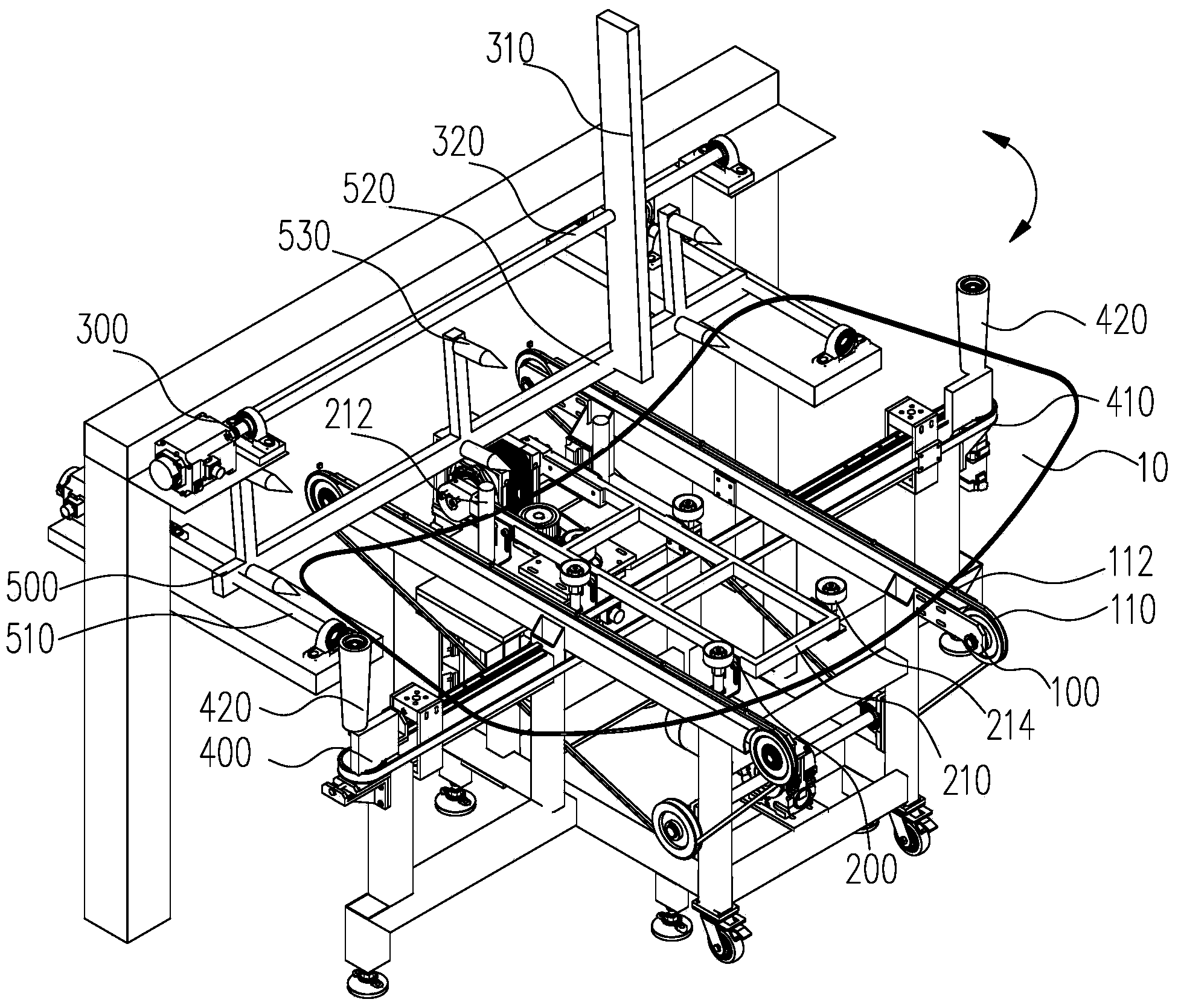

[0029] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

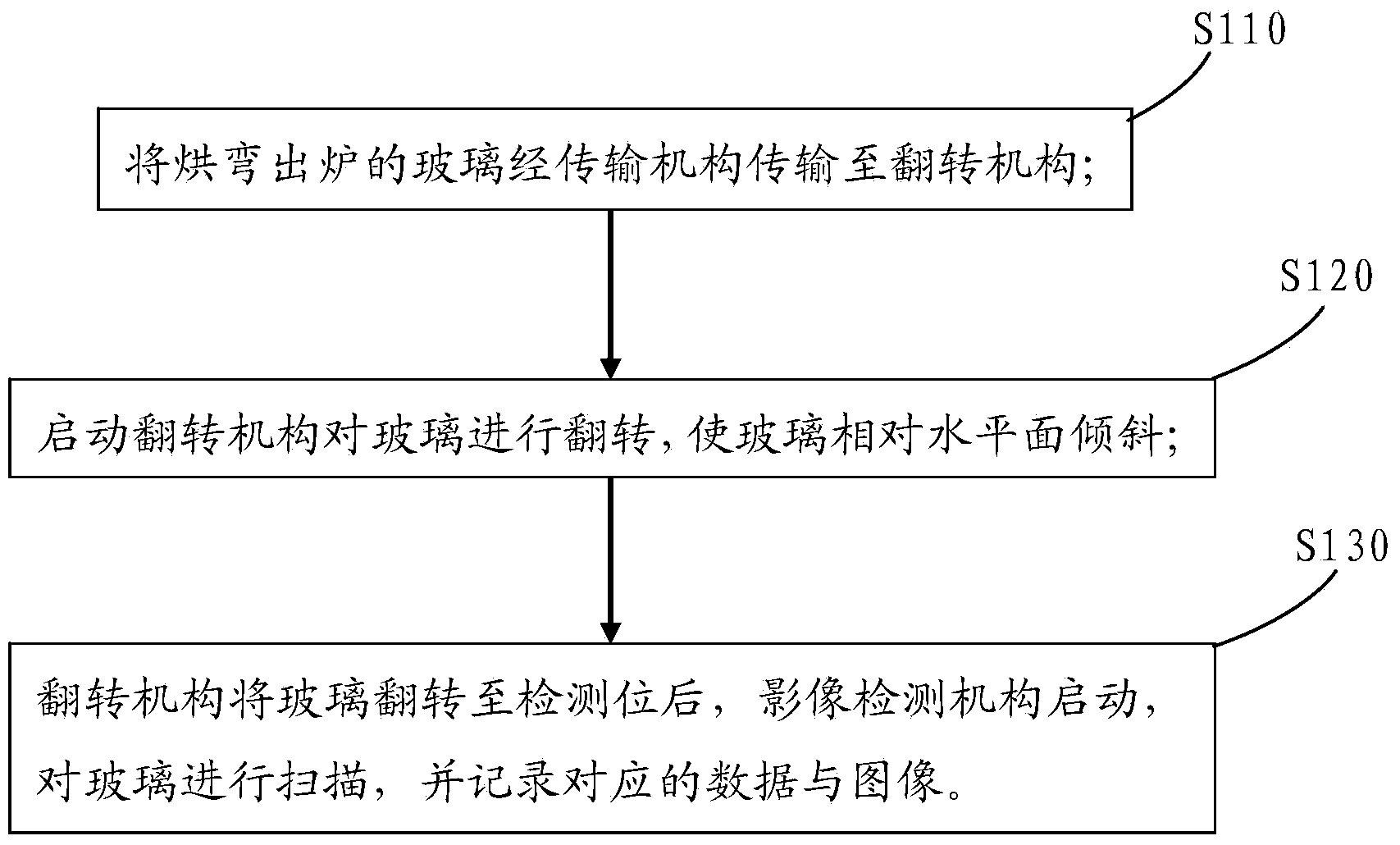

[0030] like figure 1 Shown, a kind of detection method of baking bent glass comprises the steps:

[0031] S110: transporting the bent and out-of-the-furnace glass to the turning mechanism through the transmission mechanism;

[0032] S120: activating the flipping mechanism to flip the glass so that the glass is inclined relative to the horizontal plane;

[0033] S130: After the turning mechanism turns the glass to the detection position, the image detection mechanism starts to scan the glass and record corresponding data and images.

[0034] The detection method of the bent glass described in this embodiment directly transmits the bent glass to the turning mechanism, so that the turning mechanism can turn the glass over, and by turning the glass to the detection position, the glass is tilted relative to the horizontal plane, so as to avoid bending. The final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com