High-light effect and high-power integrated LED with even light spots

A high-efficiency, high-power technology, used in semiconductor devices, electrical components, circuits, etc., can solve the problems of light spot generation, uneven and thorough phosphor excitation, poor heat dissipation, etc., to achieve high excitation efficiency, increased brightness, and quality reliability. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

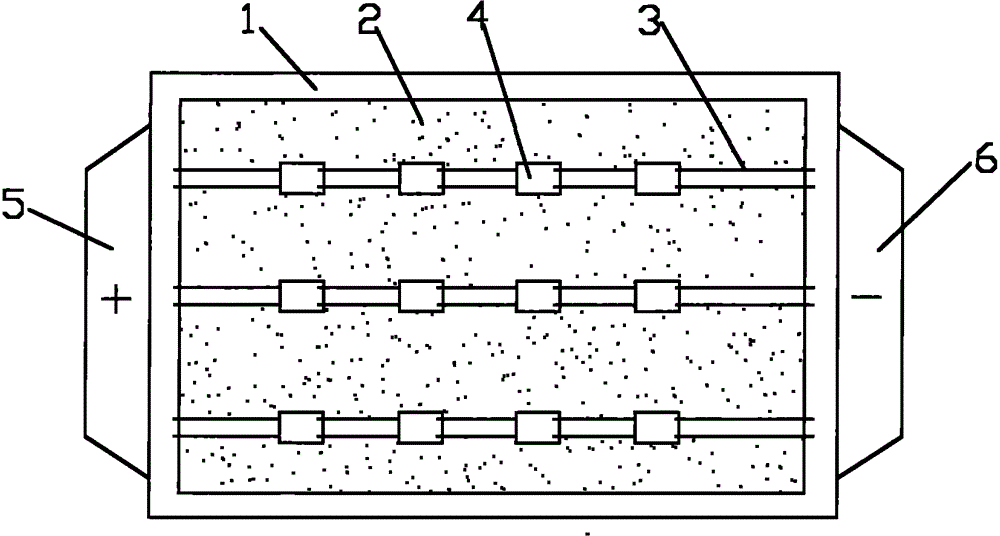

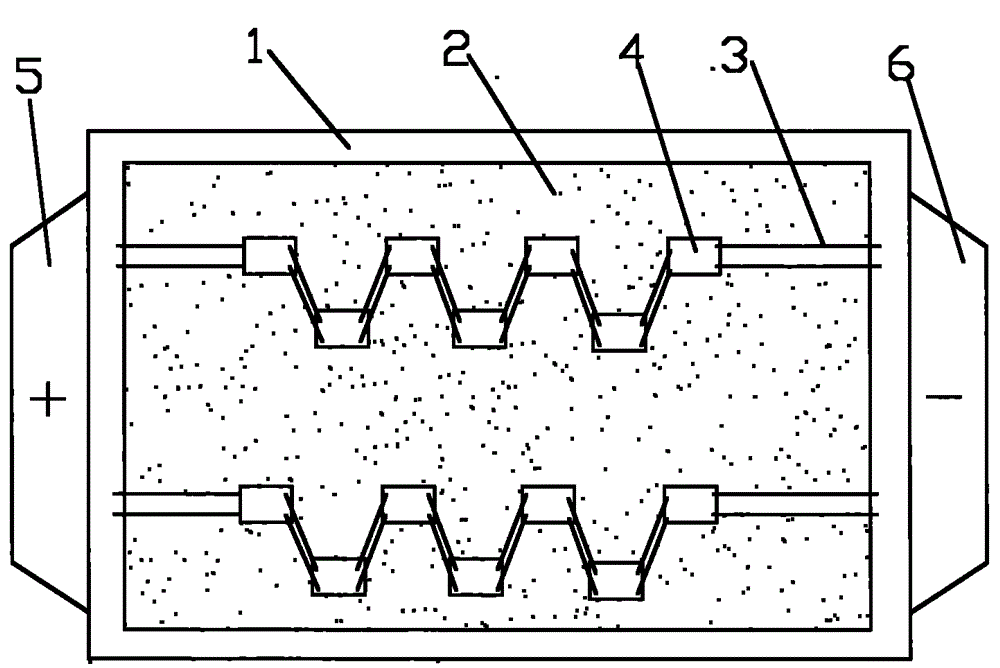

[0010] like figure 2 As shown, a high-efficiency and high-power integrated LED with uniform light spot is mainly composed of a bracket 1, a gold wire 3 and a number of chips 4. The chips 4 are fixed on the bracket 1, and the chips 4 are connected by gold wires 3. The chips at both ends 4. Connect the positive pole 5 and the negative pole 6 of the bracket 1 through the gold wire 3, the chip 4 is evenly distributed on the surface of the bracket 1 according to the S-shaped structure, and the bowl of the bracket 1 is filled with fluorescent glue 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com