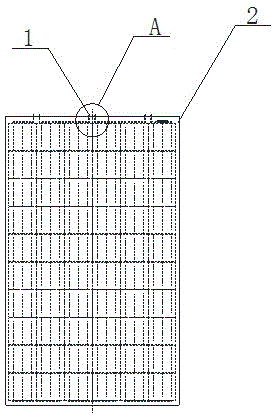

Easy-to-cut double-glass components

A double-glass module and edge-cutting technology, applied in electrical components, semiconductor devices, photovoltaic power generation, etc., can solve the problems of affecting production, low edge-cutting efficiency, low edge-cutting efficiency, etc., to facilitate cleaning and improve overall efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

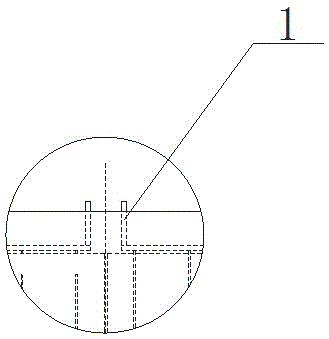

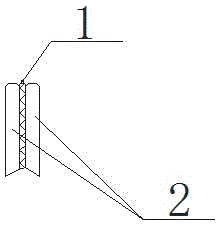

[0020] Such as Figure 4-7 As shown, in the first and optimal implementation of the double-glass assembly with easy-to-cut edges of the present invention, it includes the first glass layer 4, the second glass layer 5, the lead wire 3, the adhesive film layer 6 and the battery sheet 7 , where the lead wire 3 is bent from between the first and second glass layers 4 and 5 to the outside of the second glass layer 5 , and the tail is attached to the surface of the second glass layer 5 . Compared with the structural design of the prior art, the similar semi-closed design formed by the lead wire 3 can effectively block the glue in the gap at the thickness position of the double-glass module, so that the glue can only flow to other The position overflows, which can effectively prevent more glue from overflowing to the surface of the lead-out wire, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com