A high-efficiency white water tray sewage device

A technology of sewage discharge device and white water tray, which is applied in textile and paper making, paper machine, wet end of paper machine, etc., can solve the problems of ineffective discharge, large production loss, pollution of paper machine cloth, etc., and achieves stable liquid level, Simple transformation and stable effect of sizing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

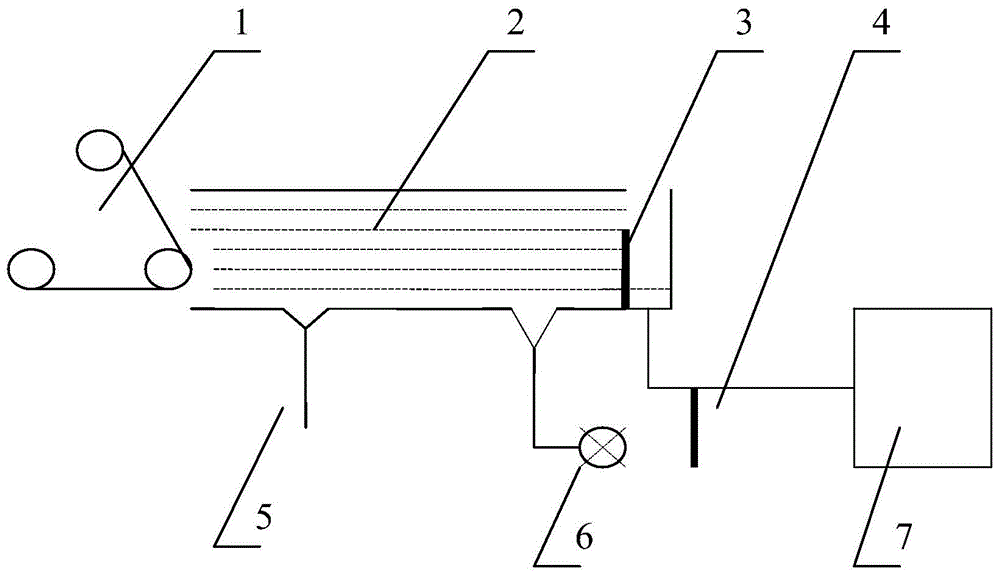

[0020] Such as figure 1 As shown, a kind of high-efficiency white water pan blowdown device, comprises paper machine net part 1, white water tank 2, heavy residue sewage pipe 5, heavy pulp pump 6, described paper machine net part 1 communicates with white water tank 2, and described The heavy slag sewage pipe 5 and the heavy slurry pump 6 are respectively arranged at the bottom of the white water tank 2, and also include an adjustable baffle 3, a light slag sewage pipe 4 and an under-machine drainage pool 7, and the adjustable baffle 3 is arranged at the white water tank 2, the white water tank 2 is divided into a sewage discharge area and an overflow area, the heavy slag sewage pipe 5 and the heavy slurry pump 6 are located at the bottom of the sewage discharge area, and the under-machine drainage pool 7 is connected to the overflow area through a pipeline, and A light slag discharge pipe 4 is arranged on the pipeline, and a regulating valve is arranged on the light slag disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com