Cylindrical linear switched reluctance motor with permanent magnet ring mover

A technology of switched reluctance motor and permanent magnet ring, applied in electromechanical devices, electrical components, electric components, etc., can solve the problem of low power density and propulsion force density, low utilization rate of ferromagnetic materials of motors, low running speed of linear motors, etc. problems, to achieve the effect of reducing dosage, simple and reliable structure, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

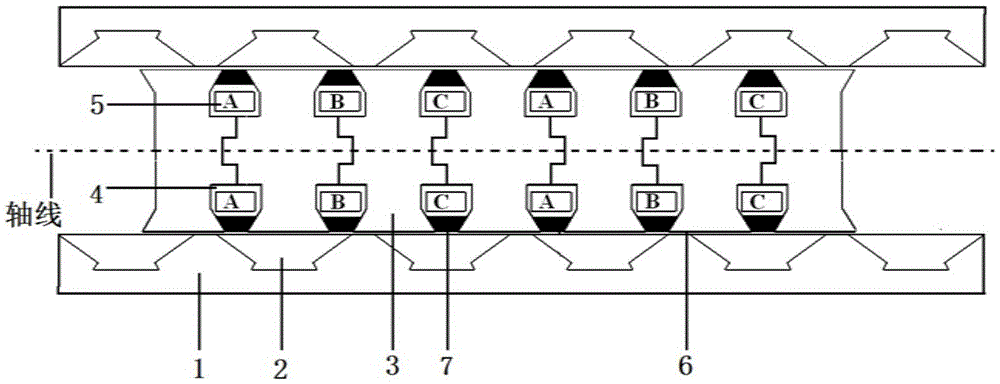

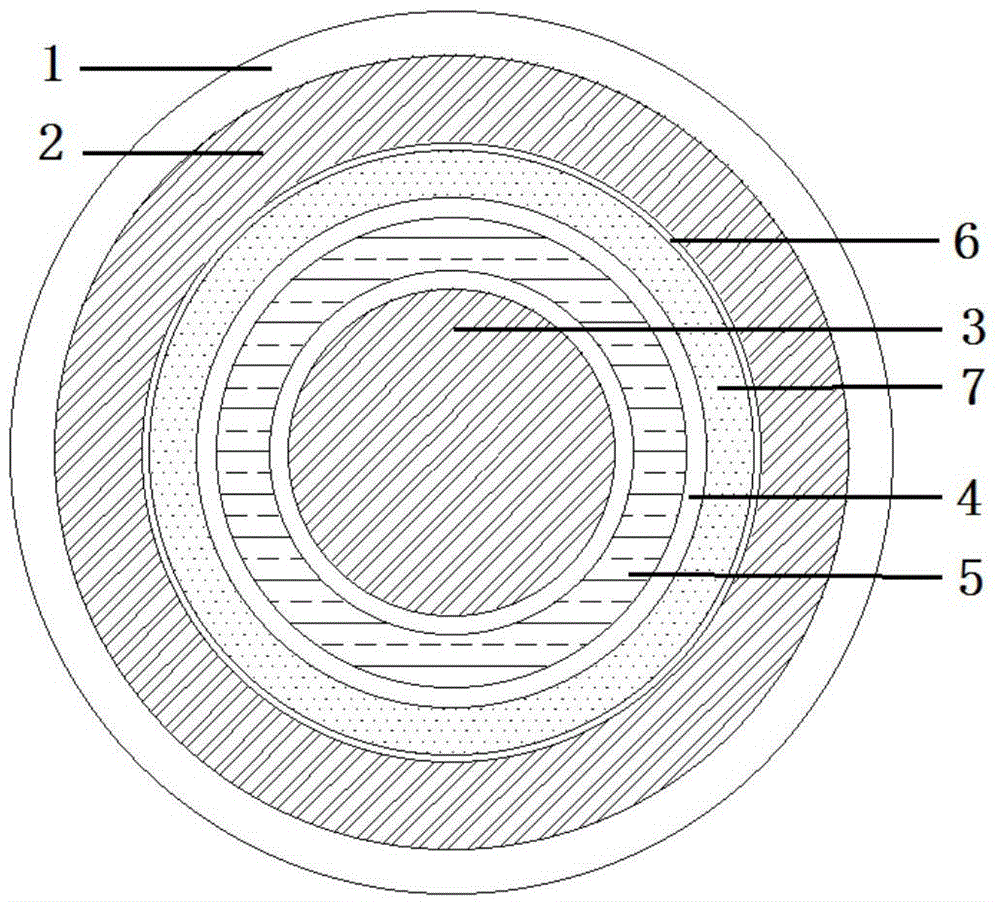

[0060] Such as figure 1 As shown, the number of motor phases in this embodiment is m=3, the number of mover poles Pt=6, the number of stator poles Ps=4, the number of mover teeth contained in the mover cylinder Nt=7, and the ring-shaped mover contained in the mover cylinder The number of slots is Qs=6, the number of permanent magnetic rings included in the mover barrel is Nm=6, and the number of magnetic conducting rings included in the stator barrel is Nr≥5. This embodiment includes a non-magnetic stator sleeve 1, a stator magnetic ring 2 is placed inside the non-magnetic stator sleeve 1, and the stator magnetic ring 2 is uniformly fixed inside the non-magnetic stator sleeve 1 along the axial direction. The axial section of the magnetic ring 2 is trapezoidal, and the bottom is processed into a special shape so as to be fixed with the non-magnetic stator sleeve 1, and the inner side of the non-magnetic stator sleeve 1 is provided with a mover core 3, and the mover core 3 and t...

Embodiment 2

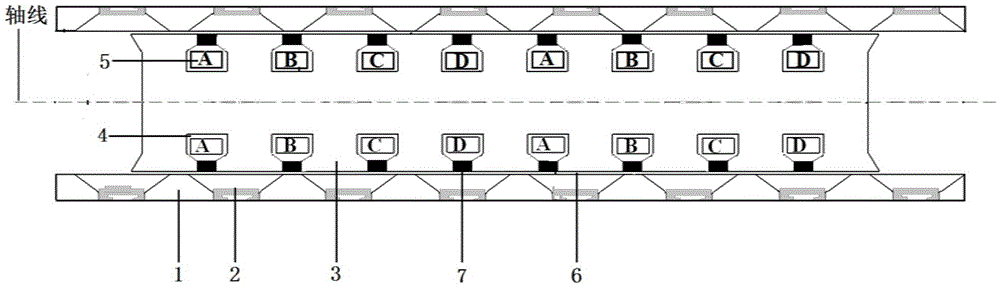

[0062] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is: 1) the number of poles of the stator and the mover of the motor are different; 2) the installation methods of the stator magnetic ring and the non-magnetic stator sleeve are different; 3) the mover core 4) The shapes of the permanent magnet rings are different. In this embodiment, the number of motor phases m=4, the number of mover poles Pt=8, the number of stator poles Ps=6, the number of mover teeth contained in the mover barrel Nt=9, and the number of annular mover slots included in the mover barrel is Qs=8, the number of permanent magnetic rings contained in the mover cylinder is Nm=8, and the number of magnetic conducting rings contained in the stator cylinder is Nr≥7. This embodiment includes a non-magnetic stator sleeve 1. A stator magnetic ring 2 is placed inside the non-magnetic stator sleeve 1. The stator magnetic ring 2 and the non-magnetic stator sleeve 1 are spliced toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com