Cylindrical linear switched reluctance motor with permanent magnet ring stator

A technology of switched reluctance motors and ring stators, which is applied in the direction of magnetic circuit shape/style/structure, electromechanical devices, electrical components, etc., and can solve problems such as low utilization rate of effective magnetic flux, reduced mass of movers, and large magnetic flux leakage , to achieve simple and reliable structure, improve tank utilization and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

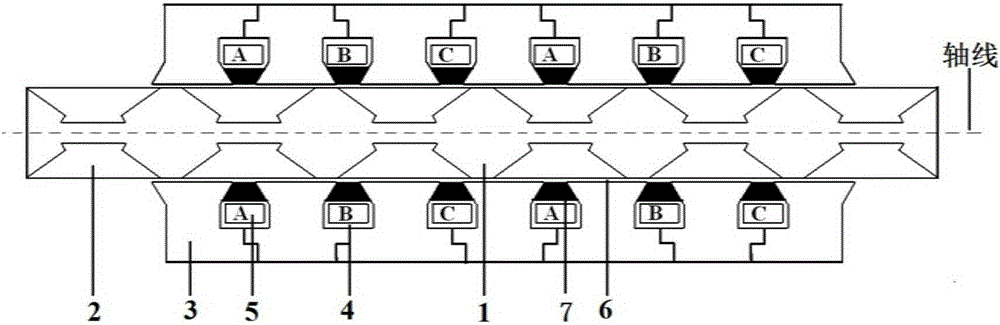

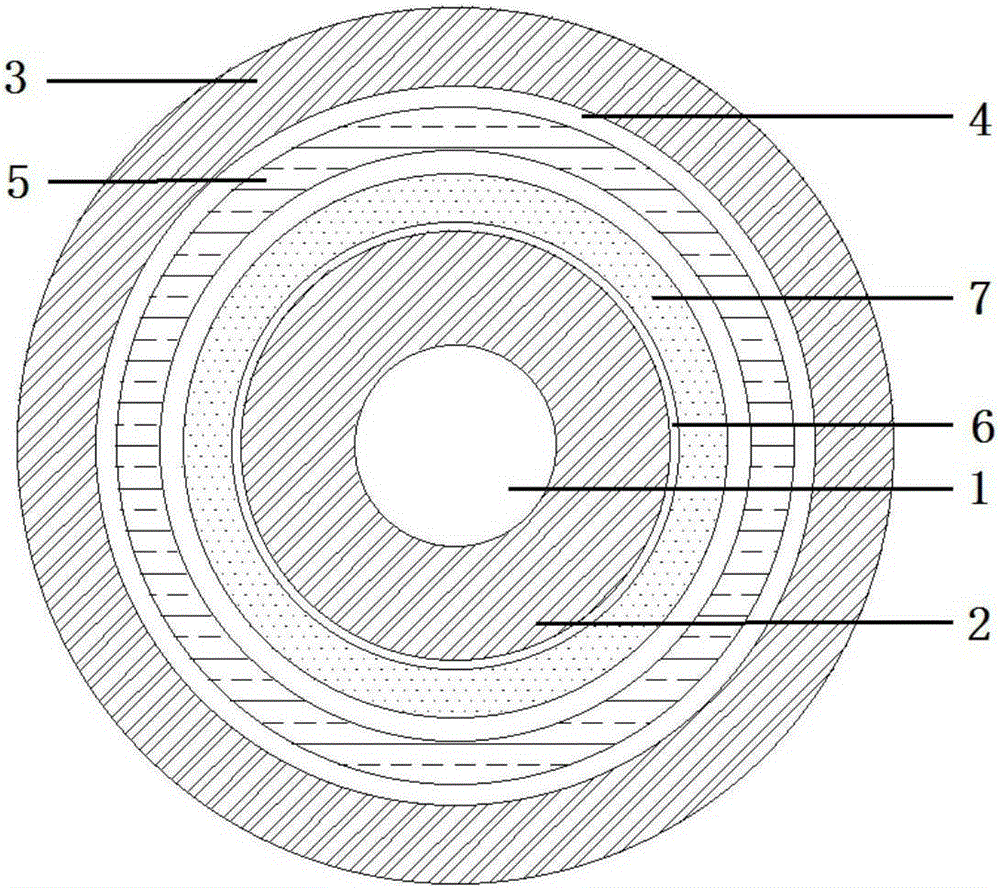

[0062] Such as figure 1 As shown, the number of motor phases in this embodiment is m=3, the number of stator poles Pt=6, the number of mover poles Ps=4, the number of teeth included in the stator barrel is Nt=7, and the number of annular stator slots included in the stator barrel is Qs= 6. The number of permanent magnetic rings is Nm=6, and the number of magnetic conducting rings contained in the mover cylinder is Ns≥5. This embodiment includes a non-magnetic mover sleeve 1, a mover magnetic ring 2 is placed inside the non-magnetic mover sleeve 1, and the mover magnetic ring 2 is uniformly fixed on the non-magnetic mover sleeve in the axial direction. 1, the axial cross-section of the mover magnetic ring 2 is trapezoidal, and the bottom is processed into a special shape so as to be fixed with the non-magnetic mover sleeve 1, and the stator core 3 is arranged on the outside of the non-magnetic mover sleeve 1 , the stator core 3 and the non-magnetic mover sleeve 1 are coaxially...

Embodiment 2

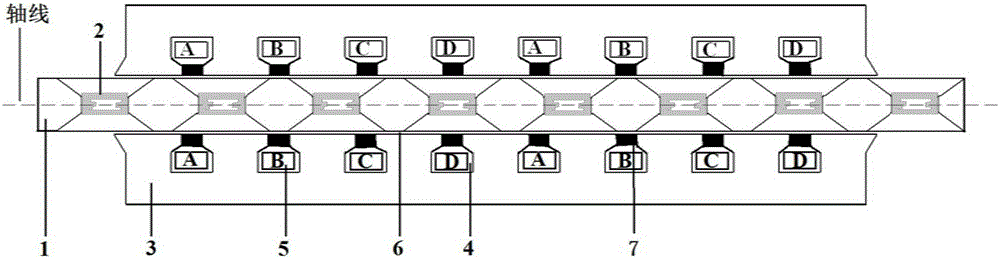

[0064] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 lies in: 1) the number of poles of the mover and the mover of the motor is different; 2) the installation methods of the magnetically conductive ring of the mover and the sleeve of the non-magnetically conductive mover are different; 3) The forming methods of the stator core are different; 4) The shapes of the permanent magnet rings are different. In this embodiment, the number of motor phases m=4, the number of stator poles Pt=8, the number of mover poles Ps=6, the number of stator teeth contained in the stator barrel Nt=9, the number of annular stator slots contained in the mover barrel Qs=8, the permanent The number of magnetic rings is Nm=8, and the number of magnetically permeable rings contained in the mover cylinder is Ns≥7. This embodiment includes a non-magnetically permeable mover sleeve 1, a mover magnetically permeable ring 2 and a non-magnetically permeable mover sleeve 1 Spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com