Carton sealing machine of production line

A technology of sealing machine and production line, applied in the direction of AC motor control, packaging sealing/tightening, external support, etc., can solve the problems of slow transmission speed and unadjustable rotation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

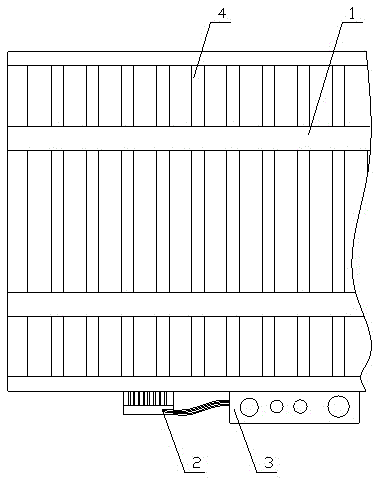

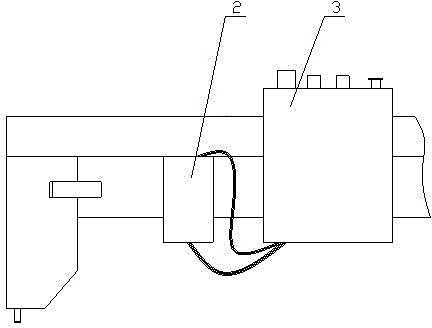

[0007] As shown in the attached figure: add frequency converter 2 to the power box of box sealing machine 1 in the traditional production line close to the end of the production line, connect the frequency converter 2 and power box 3 through wires, and under the action of frequency converter 2, the power supply frequency of the power box motor will be Adjust from 50 Hz to 60 Hz, increase the motor speed of the power box (about 1.2 times the original speed), thereby changing the transmission speed of the conveyor roller. Realize the improvement of the production efficiency of the production line sealing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com