A distributed microwave heating and drying control device and method

A microwave heating and drying control technology, applied in microwave heating, sustainable building, climate sustainability, etc., can solve the problems of manual adjustment of microwave, failure to realize microwave power, change, etc., and achieve effective and rapid transmission, heating or drying process The effect of safety and connection reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

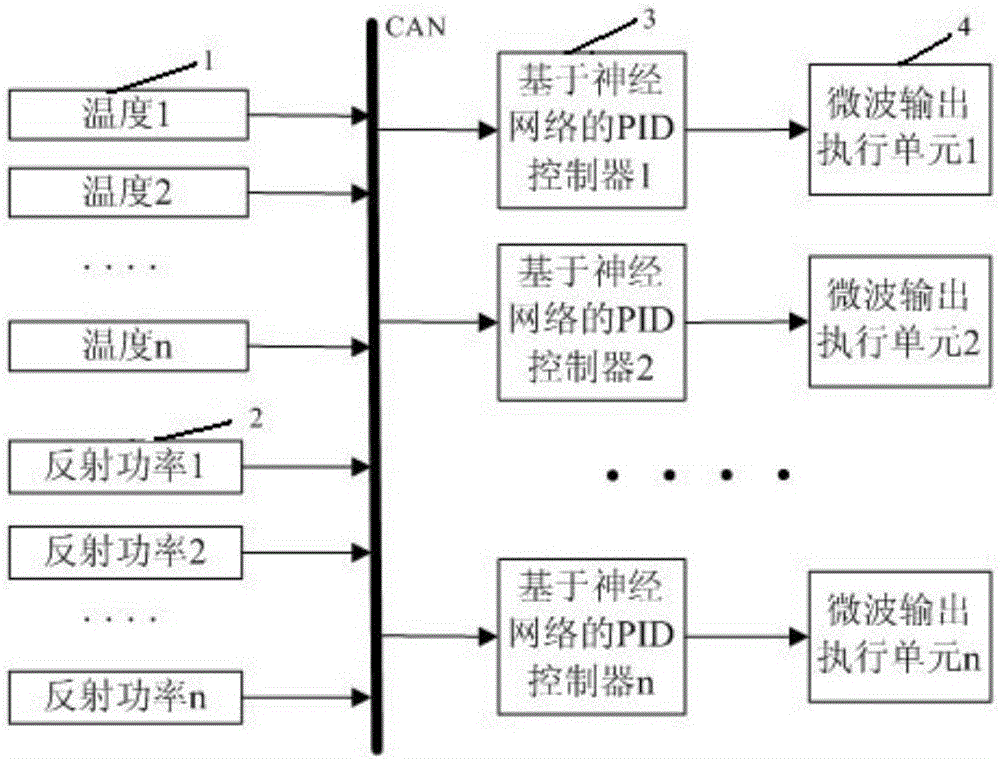

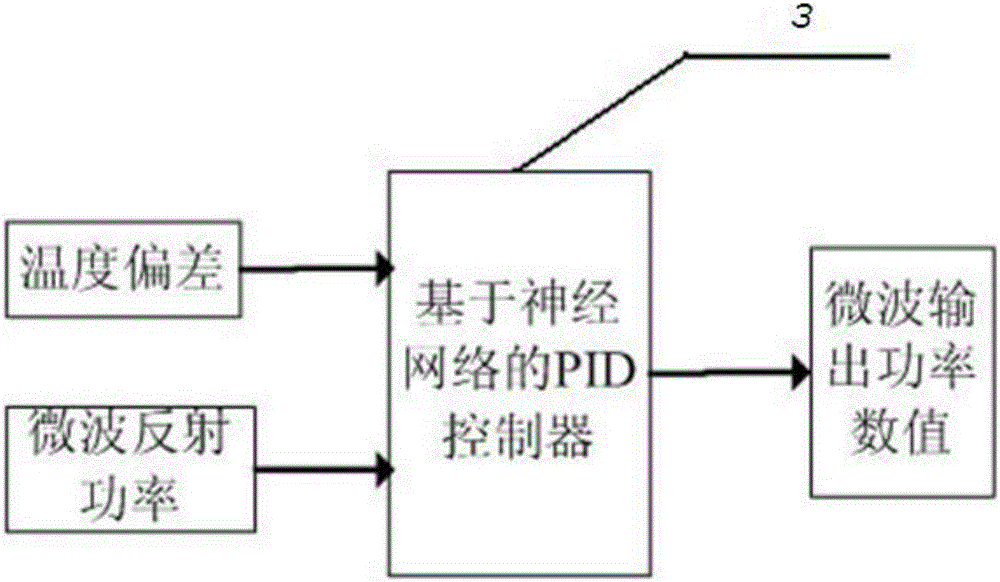

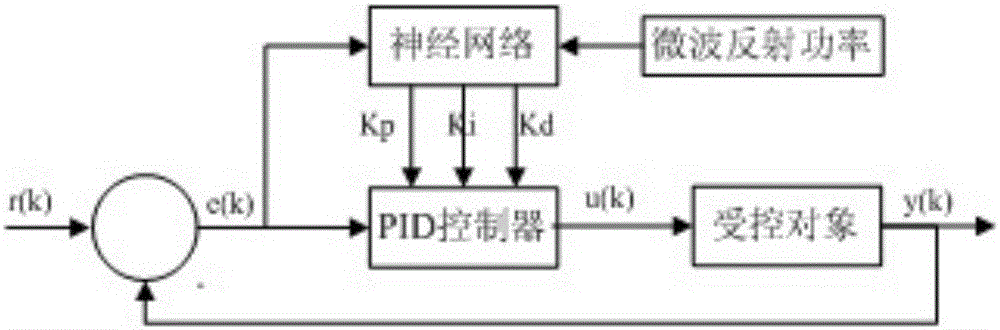

[0033] Such as figure 1 As shown, in this control scheme, n (n>=1) channels of temperature 1 and n (n>=1) channels of reflected power 2 are connected to n channels of neural network-based PID controller 3 through CAN, and n channels of neural network-based The PID controller is connected with the n-way microwave output execution unit 4. The temperature signal and reflected power signal are sent to the CAN bus, and the PID controller based on the neural network takes the corresponding temperature and reflected power from the CAN bus as its input, and sends the power value processed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com