A method for reducing coke and increasing aroma of cigarette and a kind of cigarette for reducing coke and increasing aroma

A technology for tobacco and shredded tobacco, which is applied in the preparation of shredded shredded tobacco, shredded shredded sun-dried tobacco, cigarettes with reduced tar and increased flavor, and cigarettes with reduced tar and increased flavor. Fragrance, reduction of total particulate matter and nicotine content, and quality improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1: Preparation of sample 1 of reduced tar and flavored cigarette

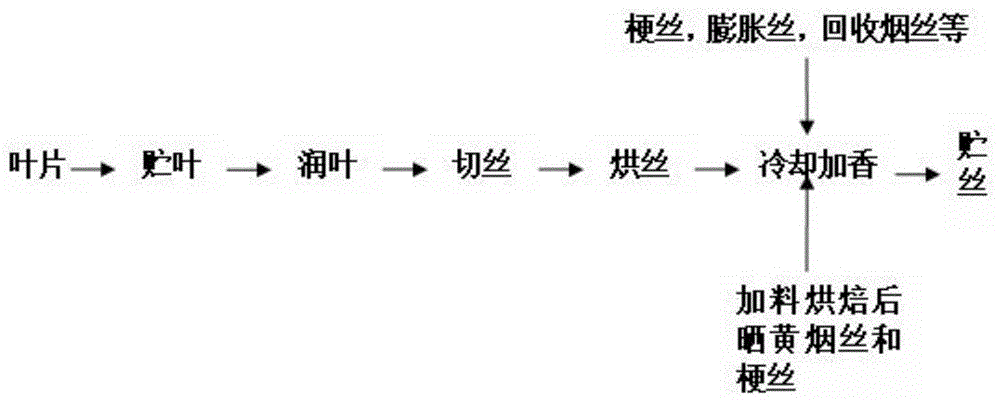

[0070] Reference attached figure 1 The process flow shown is carried out.

[0071] Specific steps are as follows:

[0072] (1) Re-moisture of smoked sheets: Send the sun-dried smoked sheets to a loosening and re-moisturizing machine for temperature increase and humidification (increase to 45°C, humidity 17%, and keep the process for about 1.5 minutes);

[0073] (2) Filling material: screen the sun-dried tobacco sheets after moisture regain, and add lining to the smoked sheets, the application amount is 13% of the weight of the sun-dried tobacco sheets, the moisture content of the leaves is controlled at 24%, and the temperature of the leaves is controlled at 57°C;

[0074] (3) Leaf storage: send the sun-dried tobacco after adding the lining material to the storage cabinet for storage, and the time is more than 2 hours;

[0075] (4) shred: shred the sun-dried tobacco sheet after leaf storage;...

Embodiment 2

[0087] Embodiment 2: Preparation of cigarette sample 2 with reduced tar and increased flavor

[0088] Reference attached figure 1 The process flow shown is carried out.

[0089] Specific steps are as follows:

[0090] (1) Re-moisture of smoked sheets: Send the sun-dried smoked sheets to a loosening and re-moisturizing machine for increasing temperature and humidification (the temperature is 45°C, the humidity is 17%, and it is kept for 1.5 minutes);

[0091] (2) Filling material: screen the sun-dried tobacco sheets after moisture regain, and add lining to the smoked sheets, the application amount is 13% of the weight of the sun-dried tobacco sheets, the moisture content of the leaves is controlled at 24%, and the temperature of the leaves is controlled at 57°C;

[0092] (3) Leaf storage: send the sun-dried tobacco after adding the lining material to the storage cabinet for storage, and the time is more than 2 hours;

[0093] (4) shred: shred the sun-dried tobacco sheet af...

Embodiment 3

[0105] Embodiment 3: sensory evaluation test

[0106] 1. Evaluate and absorb samples:

[0107] Cigarette sample 1-2 prepared in Example 1-2; and the reference sample used in Example 1-2.

[0108] 2. Evaluation methods and standards

[0109] The overall cycle smoking evaluation method is specifically carried out according to the tobacco and tobacco product sensory evaluation method YC / T138-1998 of the tobacco industry standard of the People's Republic of China.

[0110] 3. Evaluation results

[0111] As in Table 1 below.

[0112] Table 1: Cigarette sample quality evaluation and smoking results

[0113] sample

[0114] The results of sensory evaluation showed that, compared with the reference sample, the amount of aroma of samples 1-2 increased and the aroma was richer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com