Preparation of a heat-treated red mud catalyst and its application in water treatment technology

A catalyst and water treatment technology, applied in the direction of oxidized water/sewage treatment, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high cost and low catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

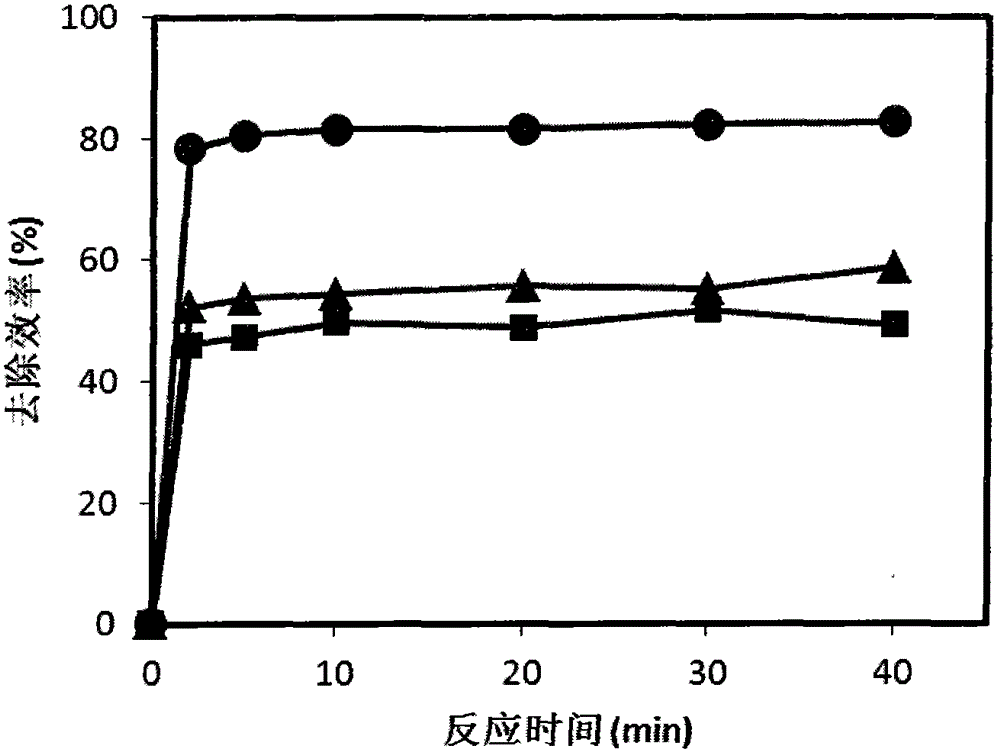

Image

Examples

specific Embodiment approach 1

[0010] Specific Embodiment 1: In this embodiment, the preparation method of the catalyst in the water treatment method of heat-treating red mud to catalyze ozone oxidation to remove organic matter in water is: (1) Cleaning, after washing an appropriate amount of raw red mud with distilled water for 5 times, remove the red mud The ash content on the surface of the raw ore is dried at 70°C; (2) Preparation for high temperature treatment, weigh 2.0-3.0 grams of the cleaned red mud, put it in a cleaned and dried porcelain crucible, and cover the porcelain crucible Put the crucible cover in the muffle furnace for high temperature treatment; (3) high temperature treatment conditions, take 8~12℃ / min as the heating rate, raise the temperature in the muffle furnace to 390~410℃, and increase the temperature at 390~410℃ Keep warm at ℃ for 3.5-4.5 hours; (4) Cooling conditions, take 8-12 ℃ / min as the cooling rate, reduce the temperature in the muffle furnace to 23-27 ℃, and keep it at 23-2...

specific Embodiment approach 2

[0014] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the application method of heat-treated red mud catalyst in water treatment is as follows: the polluted water body first undergoes primary sedimentation primary treatment-aeration biochemical-secondary sedimentation secondary treatment Afterwards, heat treatment is carried out on the red mud catalyst to catalyze ozone oxidation treatment, and then the water is discharged after post-treatment.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the raw red mud ore in the preparation step (2) of the catalyst is in a block shape. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com