Polar plate of novel electrostatic dust-collection purifying equipment

A technology for electrostatic dust removal and purification equipment, applied in the field of new electrostatic dust removal and purification equipment, can solve the problems of increasing the capacity of the whole machine, many faults, breakdown, etc., and achieve the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

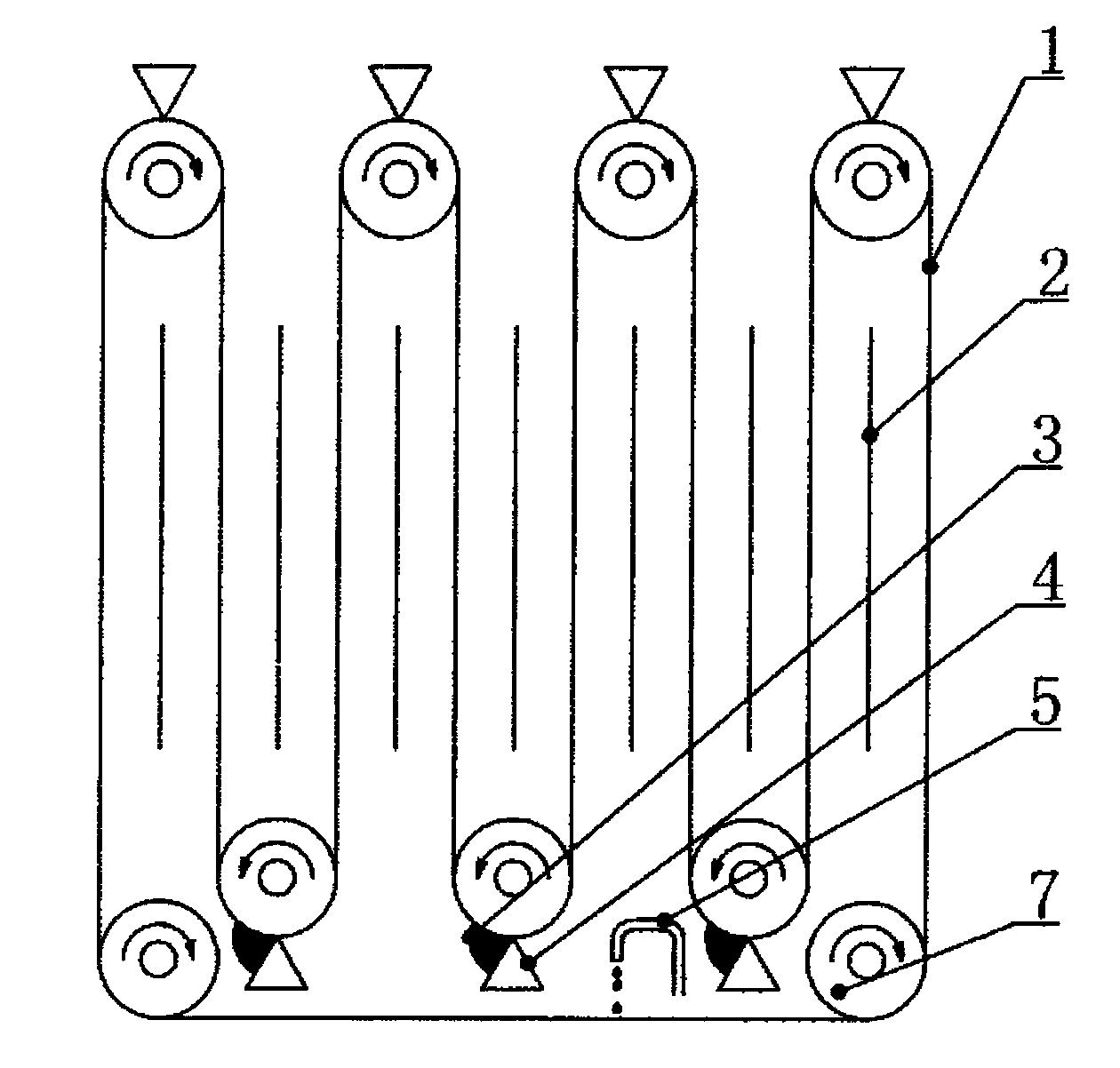

[0032] see figure 1 Schematic diagram of the structure of Embodiment 1 of the present invention. This embodiment makes full use of the flexibility of the cloth dust-collecting pole plate, and makes the cloth dust-collecting pole plate into a crawler-shaped pole plate, which is set on the rollers. When the cloth dust-collecting pole plate of conductive water is used for scraping the sewage, a decontamination scraper can be set outside the high-voltage electric field.

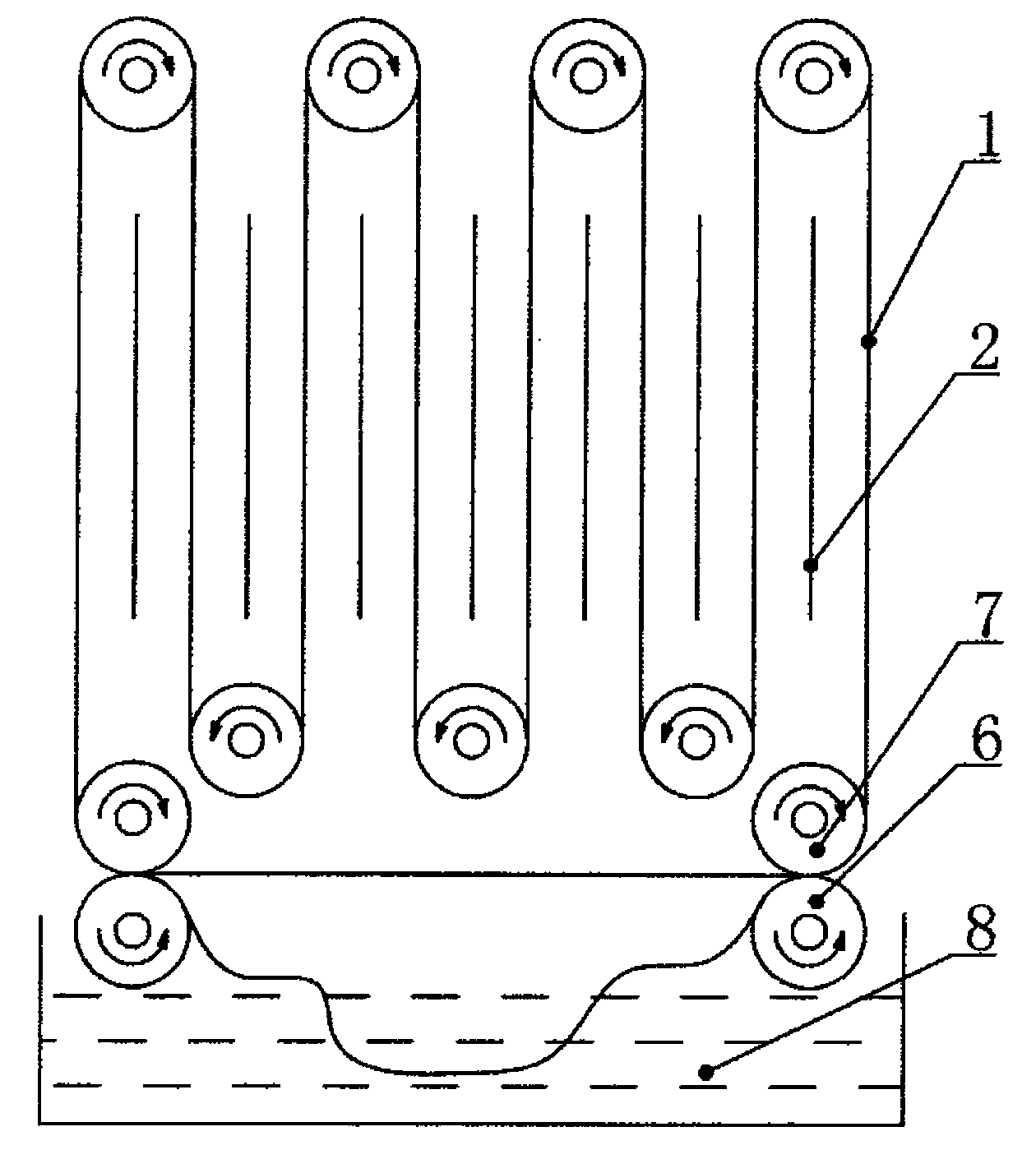

[0033] see figure 2 Schematic diagram of the structure of Embodiment 2 of the present invention. This embodiment makes full use of the flexibility of the cloth dust-collecting pole plate, and also makes the cloth dust-collecting pole plate into a crawler-shaped pole plate, which is set on the roller. The difference Yes, the cleaning of the cloth dust-collecting pole plate stained with conductive water outside the high-voltage electric field uses a cleaning pool to clean the cloth dust-collecting pole plate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com