Fast processing device and method for polygonal inner hole

A processing device and polygon technology, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve problems such as constraints and backward processing methods, and achieve the effects of low manufacturing cost, low processing cost and control of processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The device and method for rapid processing of polygonal inner holes according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

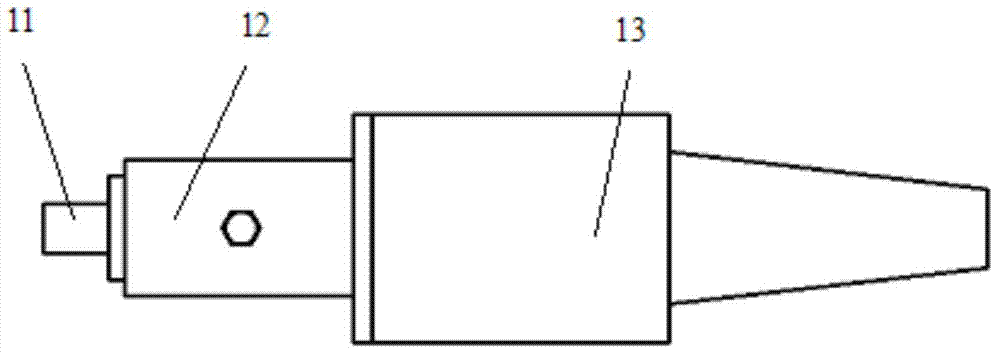

[0024] like figure 1 As shown, a polygonal inner hole rapid processing device according to the present invention includes a tool 11 , a connecting rod 12 and a rotating mechanism 13 connected in sequence.

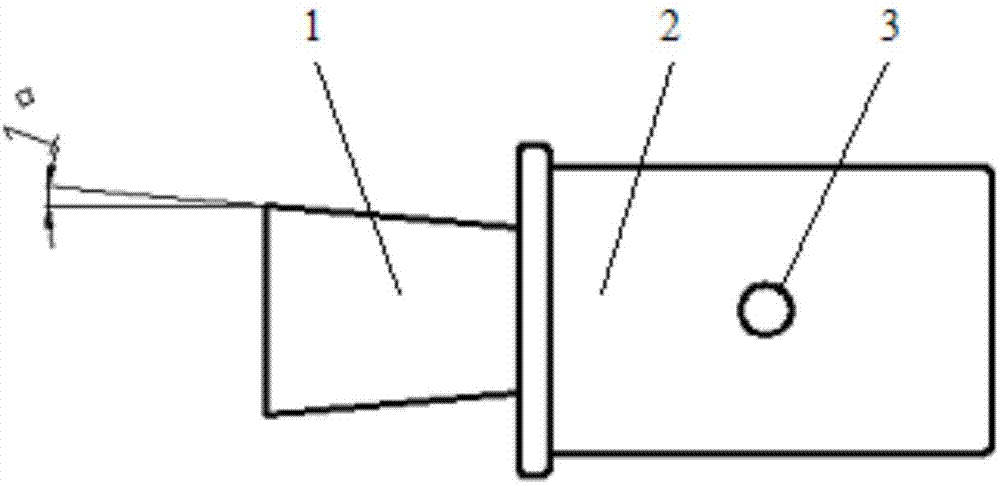

[0025] like figure 2 As shown, the cutter 11 includes a cutter head 1 and a cutter bar 2 made of high-speed steel as a whole, the rake angle of the cutter head 1 is 0°, and the rear angle of the cutter head 1 is sharpened at 1°; The positioning hole 3 matched with the threaded hole 5 of the connecting rod 12. Other dimensions of the cutter head 1 need to be sharpened according to the actual production size requirements.

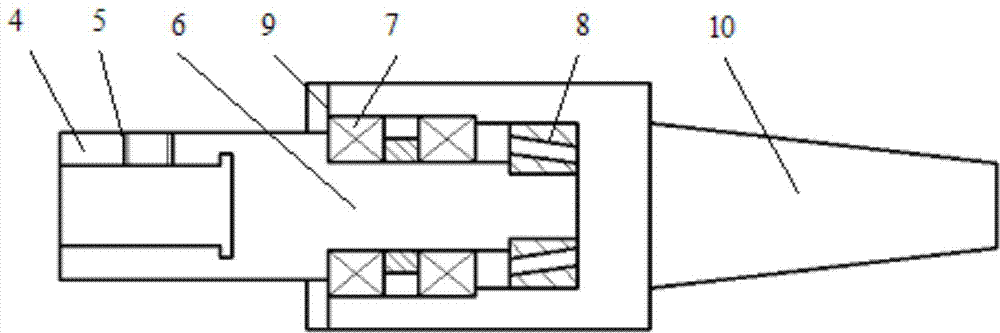

[0026] like image 3 As shown, the front end of the connecting rod 12 is a knife rod sleeve 4, and a threaded hole 5 is provided at the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com