Dual-translation orthogonal decoupling parallel micro-positioning platform

A technology of micro-motion platform and two-translational motion, which is applied in the field of manufacturing, can solve the problems that the structure has not been completely decoupled, and the stiffness of the micro-motion platform has not been considered, so as to achieve good dynamic characteristics, enhance stiffness and bearing capacity, and meet the requirements of precision machining and The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

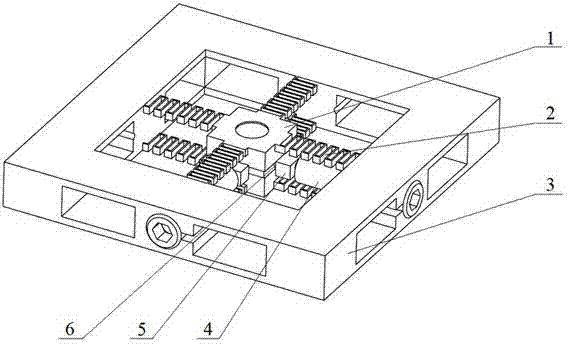

[0011] The moving workbench 1 is a cube, and the centers of two adjacent sides have horizontal semicircular grooves. The fixed platform 3 is a rectangular block with a square groove in the middle, which is connected between the moving workbench 1 and the fixed platform 3 and is located above. The four motion branch chains 2 and the four motion branch chains 2 located below are uniformly distributed about the line connecting the geometric centers of the top and bottom surfaces of the motion table 1. All the motion branches 2 are in the shape of a "bow" and are located at the top One end of the four motion branch chains 2 is respectively connected to the four side surfaces of the motion table 1, and the other end is respectively connected to the four sides of the square groove of the fixed platform 3, and the "bow" of the four motion branch chains 2 located above The top surface of the glyph is coplanar with the top surface of the movement table 1. One ends of the four movement br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com