Robot system

A robot system and robot hand technology, applied in the field of robot systems, can solve the problems of complexity, limited configuration accuracy, high-tech robot arm or robot hand motion control, and achieve the effect of simplifying motion control and improving motion reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

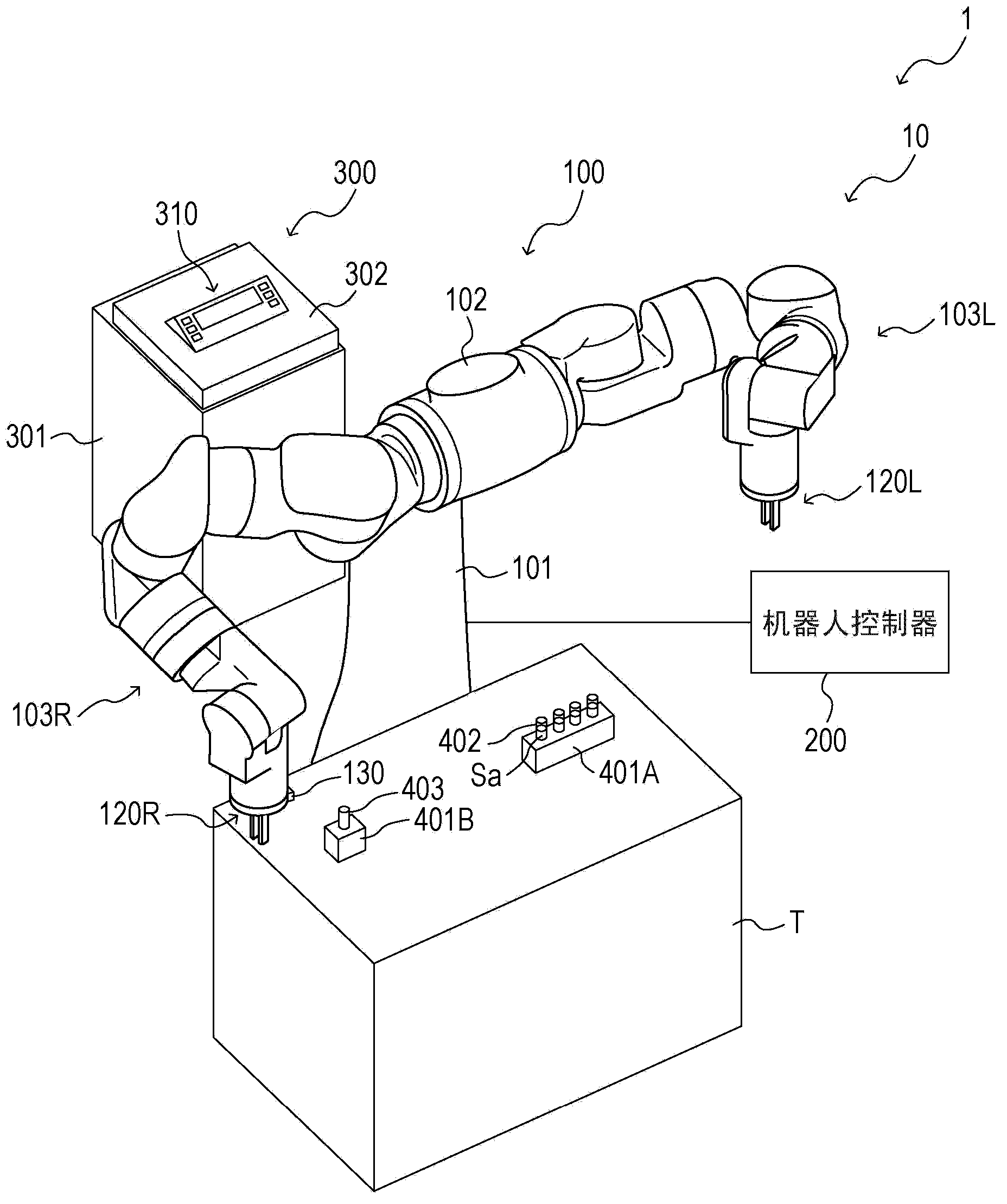

[0033] Hereinafter, an embodiment will be described with reference to the drawings. In this embodiment, a series of work examples by the robot system are shown. This work includes a work of inserting a pipe into an insertion hole provided in a rotor of the centrifugal separator and a work of pulling out the pipe from the insertion hole.

[0034] First, refer to figure 1 An example of the overall configuration of the robot system according to this embodiment will be described.

[0035] like figure 1 As shown, the robot system 1 of the present embodiment has a robot system 10 and a centrifugal separator (also referred to as a centrifuge, centrifuge, centrifuge, etc.) 300 . In addition, the centrifugal separator 300 corresponds to a rotating device.

[0036] The robot system 10 has a robot body 100 and a robot controller 200 . The robot main body 100 and the robot controller 200 are connected by wire or wirelessly in a mutually communicable manner. In addition, a robot cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com