Seedling taking mechanism for automatic transplanter

A transplanting machine and automatic technology, applied in the field of agricultural machinery, can solve the problems of unsatisfactory, large driving torque, easy to damage seedlings, etc., and achieve the effect of easy implementation and installation, realization of motion control, and meeting the requirements of seedling picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

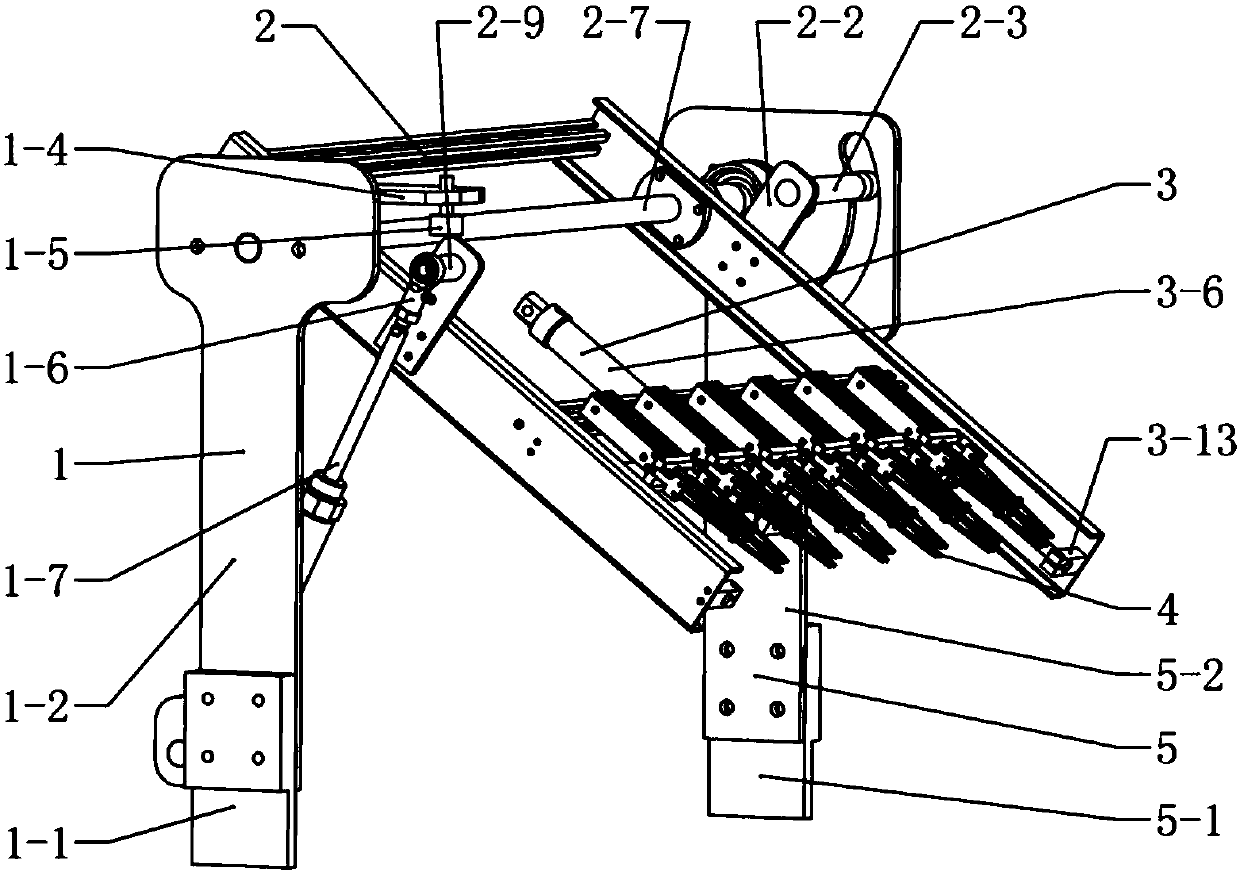

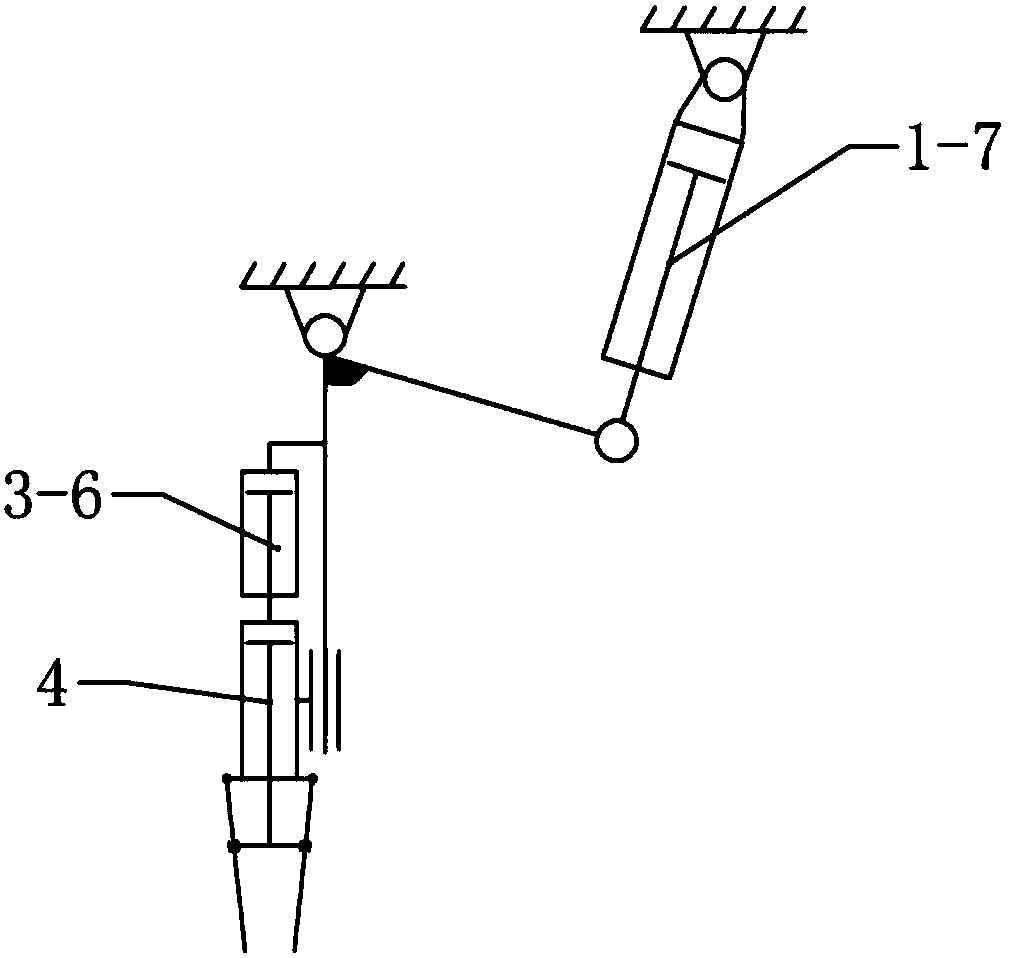

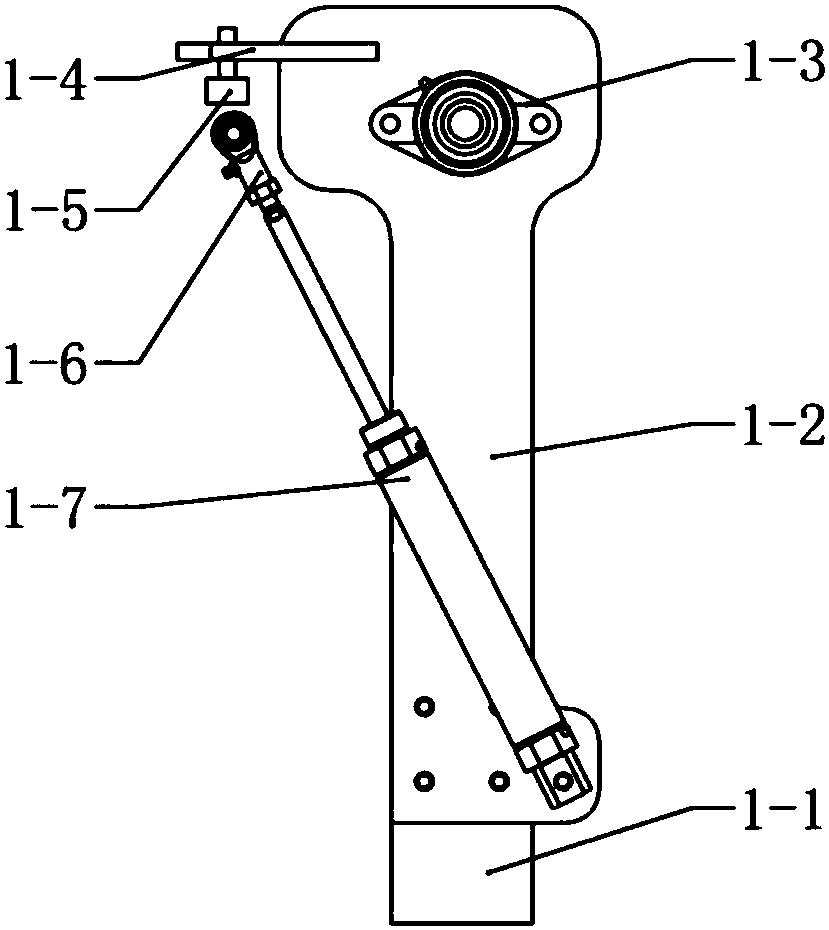

[0035] like figure 1 As shown, the seedling picking mechanism of the present invention includes a turning mechanism 1, a seedling picking frame 2, a plugging mechanism 3, a seedling picking claw 4 and a right side plate 5. The overturning cylinder 1-7 of the overturning mechanism drives the seedling picking rack 2 to turn over from the vertical seedling throwing point to the seedling picking position, and the plugging and pulling cylinder 3-6 of the plugging mechanism 3 drives the entire row of seedling picking claws 4 to insert into the seedling pot, and the seedlings are taken at the same time Claw 4 clamps the seedling pot, inserting and pulling out cylinders 3-6 drives the entire row of seedling-picking claws 4 to pull out the seedling pot, and then turns over cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com