Non-metal sound barrier die

A sound barrier and non-metallic technology, applied in the direction of molds, mold auxiliary parts, etc., can solve the problems of inability to adjust mold size, complex production process, and inflexible design, etc., and achieve the effect of simple production, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

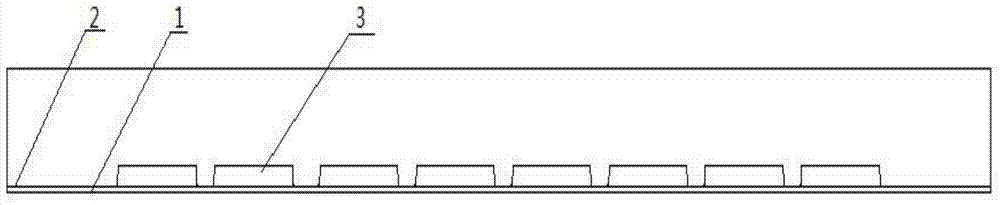

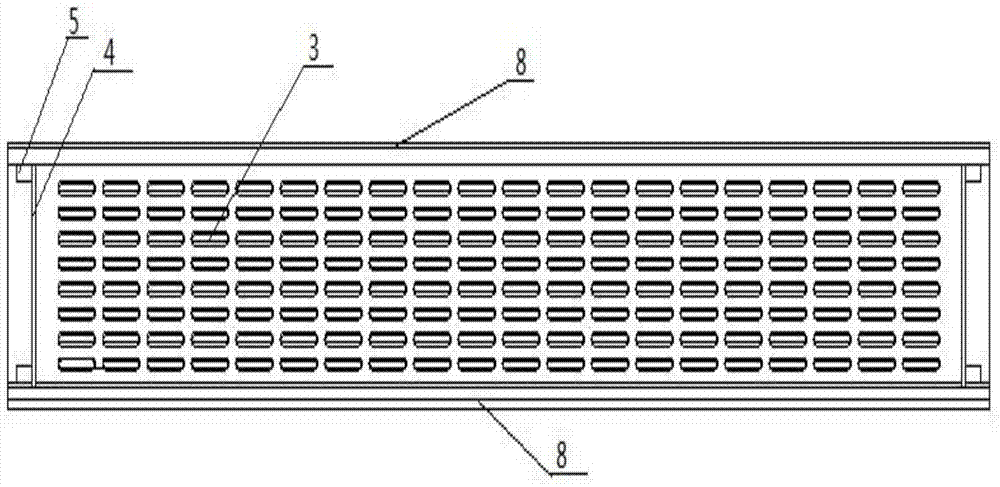

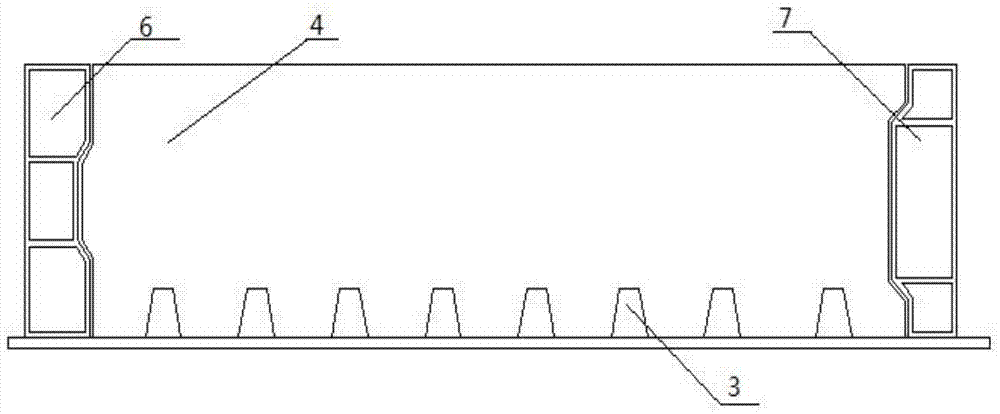

[0019] A non-metallic sound barrier mold of the present invention, comprising a plate body 1 , the plate body 1 is covered with a layer of galvanized steel plate 2, the four right angles of the plate body 1 are reinforced with angle steel, side baffles 8 are arranged on both sides of the plate body 1, and the two ends of the plate body 1 A terminal baffle 4 is provided, and a limit block 5 is provided on the outside of the terminal baffle 4. Several rubber modules 3 are fixed on the board body 1 with rivets (the number of rubber modules depends on the need), and the rubber Modules 3 are evenly distributed on the board. In order to increase the muffler effect of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com