Heat treatment molding method of thermoplastic wound pipe

A forming method and technology of winding tube, which are applied in the field of thermoplastic winding tube forming and heat treatment forming of thermoplastic winding tube, can solve the problems of easy cooling and solidification, poor bonding performance, etc., and achieve high strength and pressure resistance, high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

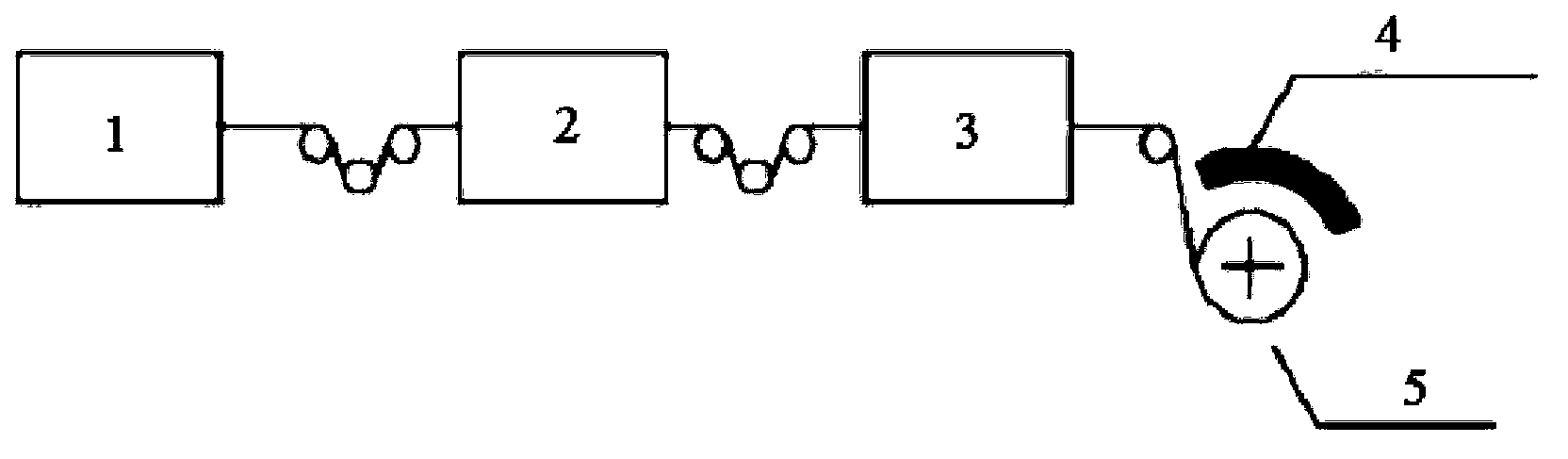

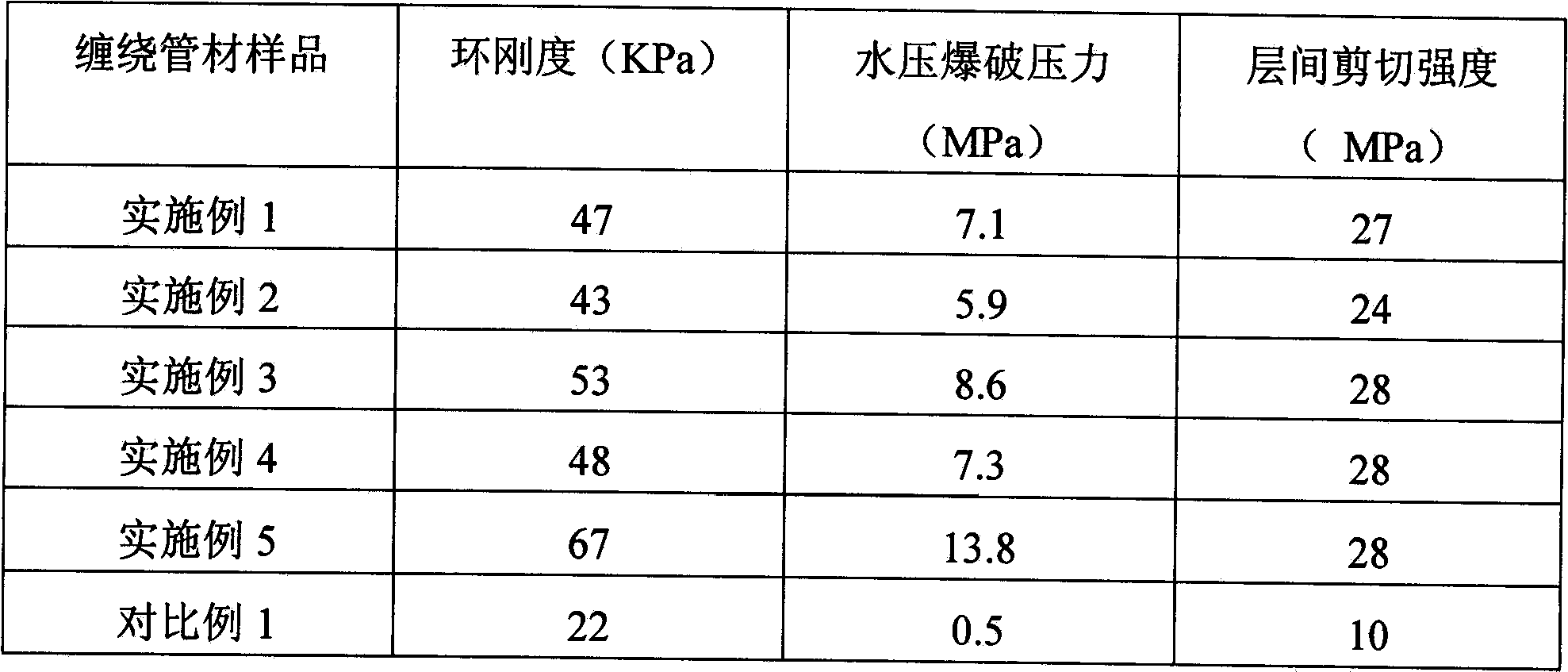

[0020] The prepreg tape material used for thermoplastic winding pipe is continuous glass fiber reinforced polypropylene prepreg tape, which is produced by Shanghai Jieshijie New Material (Group) Co., Ltd. Such as figure 1 As shown, the infrared online heating treatment method is adopted in the winding process, in which three infrared tube heaters are used to heat the prepreg tape before it is wound on the core mold 5, and the infrared heating cover 4 is used to heat the core mold 5. The temperature at the infrared heater 1 is set to 70-80°C, the temperature at the infrared heater 2 is set to 120-140°C, and the temperature at the infrared heater 3 is set to 160-190°C. temperature of the heater. The temperature of the infrared heating mantle 4 heated to the mandrel is set at 200-250°C. The above temperatures are the measured temperatures when the prepreg is brought out of the heater, and the temperature setting of the heater is adjusted accordingly according to the winding spe...

Embodiment 2

[0022] The prepreg tape material used for thermoplastic winding pipe is continuous glass fiber reinforced polypropylene prepreg tape, which is produced by Shanghai Jieshijie New Material (Group) Co., Ltd. During the winding process, the heated and melted prepreg tape is directly wound on the mandrel, and then the mandrel with the wrapped prepreg tape is heated in an oven at 200°C for 1.5 hours, taken out, and rolled with a pressure of 0.4MPa. Wherein, three infrared tube heaters are used to heat the prepreg tape before it is wound on the mandrel 5 . The temperature of infrared heater 1 is set to 70-80°C, the temperature of infrared heater 2 is set to 120-140°C, and the temperature of infrared heater 3 is set to 160-190°C. The above temperatures are all when the prepreg is brought out of the heater The measured temperature, the temperature setting of the heater is adjusted accordingly according to the winding speed. The properties of the obtained thermoplastic FRP wound pipe a...

Embodiment 3

[0024] The prepreg tape material used for thermoplastic winding pipe is continuous aramid fiber reinforced polyethylene prepreg tape, which is produced by Shanghai Jieshijie New Material (Group) Co., Ltd. use as figure 1 In the shown infrared online heating treatment method, the infrared heater adopts an infrared ceramic sheet. Wherein, before the prepreg tape is wound on the mandrel 5, three infrared ceramic heaters are used to heat it, and the mandrel 5 is heated by an infrared ceramic mantle 4. The temperature at the infrared heater 1 is set to 50-60°C, the temperature at the infrared heater 2 is set to 90-100°C, and the temperature at the infrared heater 3 is set to 140-160°C. temperature of the heater. The temperature of the infrared heating mantle 4 heated to the mandrel is set at 190-220°C. The above temperatures are the measured temperatures when the prepreg is brought out of the heater, and the temperature setting of the heater is adjusted accordingly according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com