Rapidly-disassembling device of small automobile hub nut

A dismantling device and car technology, which is applied to wheel assembly equipment, wheels, vehicle parts, etc., can solve the problems of primitive dismantling means, high working intensity, low production efficiency, etc., and achieves simple device structure, convenient operation, and improved disassembly the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

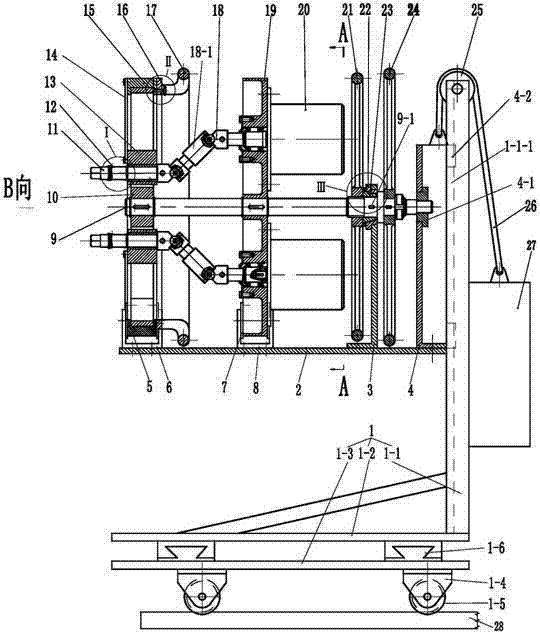

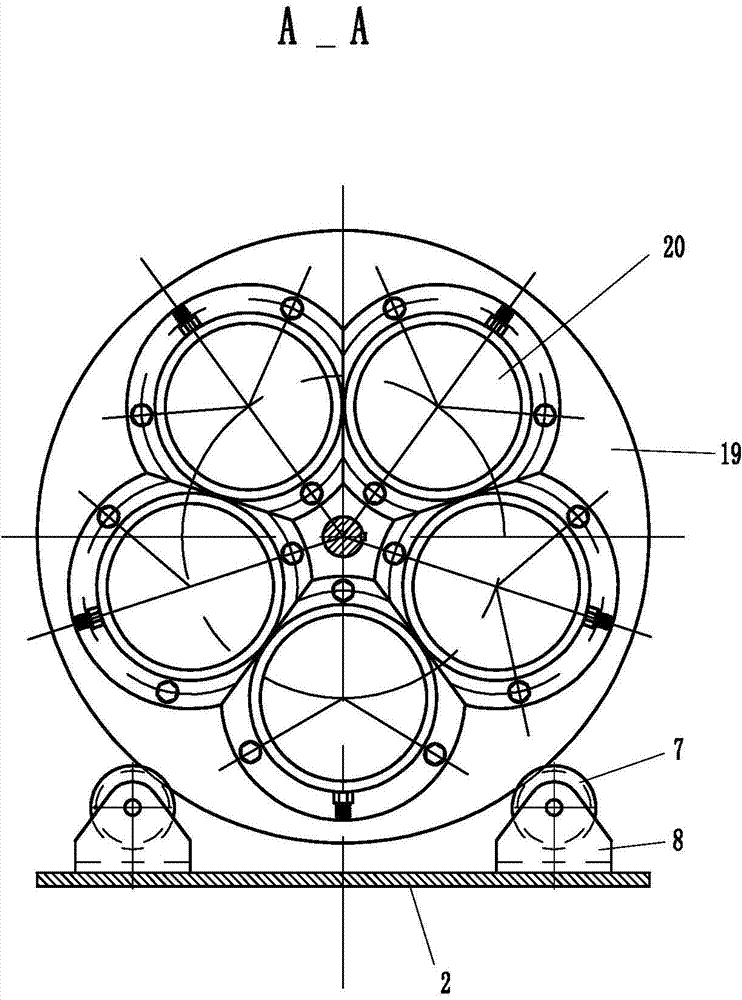

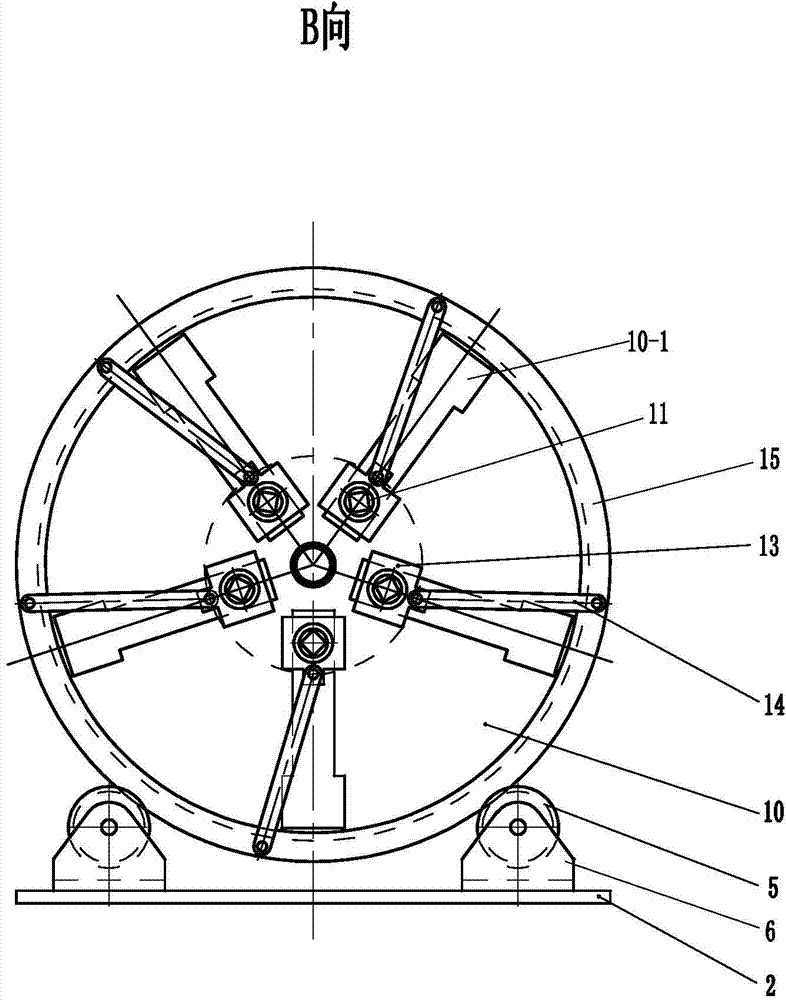

[0020] See accompanying drawing, present embodiment comprises frame 1, supporting plate 2, front bearing frame 3, rear bearing frame 4 and support shaft 9. Front bearing frame 3 and rear bearing frame 4 are fixed on the supporting plate 2, and support shaft 9 passes through front bearing frame shaft hole and rear bearing frame shaft hole. The shaft hole of the front bearing frame 3 is a tapered hole, and the tapered hole is provided with an outer taper sleeve 22 as a sliding bearing. A sliding bearing 4-1 is provided in the shaft hole of the rear bearing frame 4.

[0021] On the support shaft 9 and on the front side of the front bearing frame 3, an adjustment face plate 10, a mounting plate 19 and a locking hand wheel 21 are connected from front to back, and on the support shaft 9, the rear adjustment hand wheel is connected on the rear side of the front bearing frame 3. Wheel 24, upper adjustment faceplate 10, installation disc 19, rear adjustment handwheel 24 and support sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com