Sanding device for railway vehicles

A technology of sand spreading device and rail vehicle, applied in the field of sand spreading equipment, can solve the problems of small amount of sand, water accumulation in pipelines, and poor fluidity of sand, etc., so as to facilitate fault finding and maintenance and prevent safety accidents. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

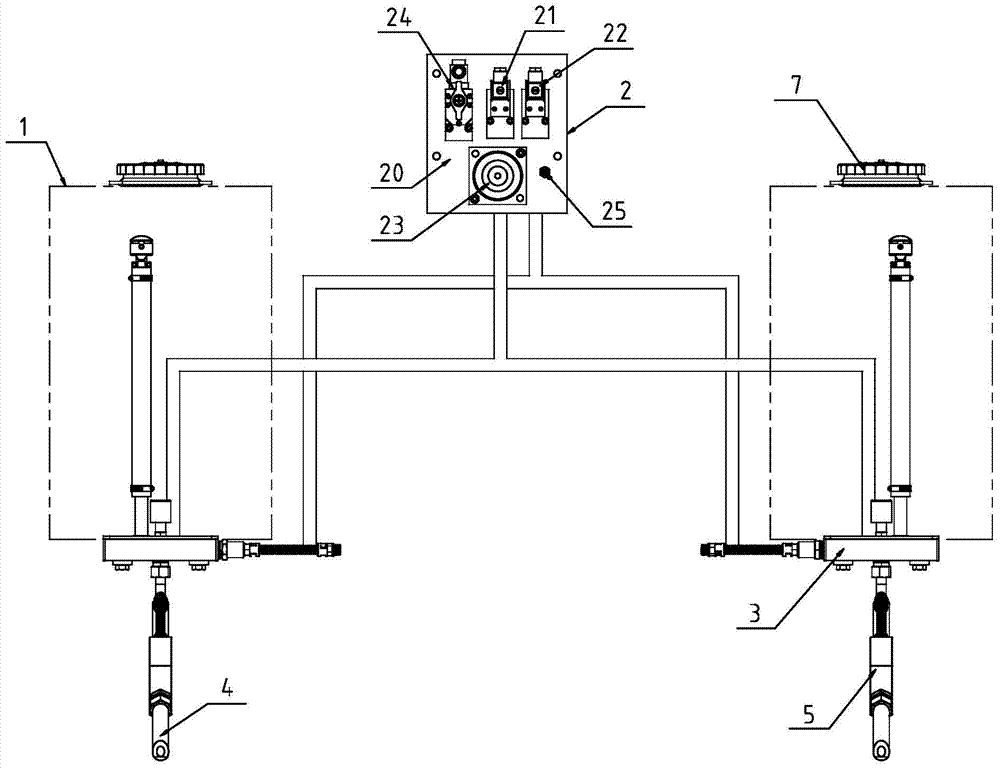

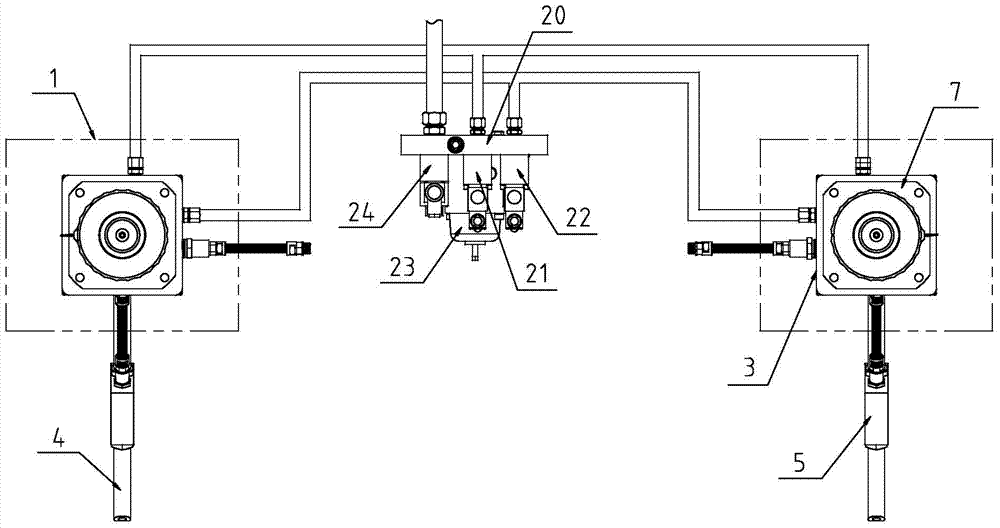

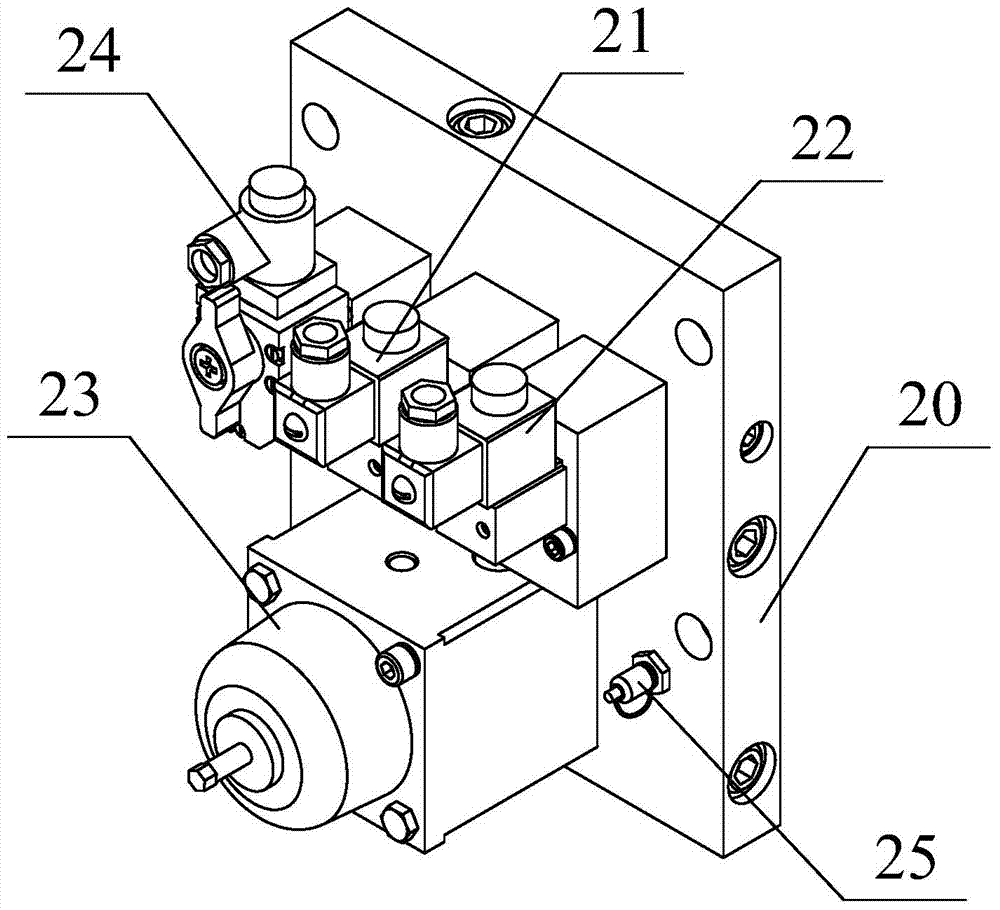

[0027] A sanding device for rail vehicles, including two sand boxes 1, two sanding units and a sanding control module 2, the sanding unit includes a sanding device 3 and a sanding pipe 4, and the sanding device 3 is installed It is located at the bottom of the sand box 1 and communicated with the sand box 1. A sand spreading heating box 5 is connected between the sand spreading device 3 and the sand blasting pipe 4; the sand spreading control module 2 includes an air circuit board 20 on which the There are a sand spreading solenoid valve 21, a drying solenoid valve 22 and a pressure reducing valve 23, wherein the sand spreading solenoid valve 21 is connected with the sand spreading air inlet S provided on the sand spreading device 3 through an air pipe, and is used to control the sand spreading supply. The air flow of the wind is cut off, the drying solenoid valve 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com