Ship mooring gear

A mooring device and ship technology, applied in ship parts, ship construction, transportation and packaging, etc., can solve problems such as anchor breakage, troublesome mooring, and laborious anchor lifting, and achieve the effect of avoiding anchor loss and saving anchor lifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

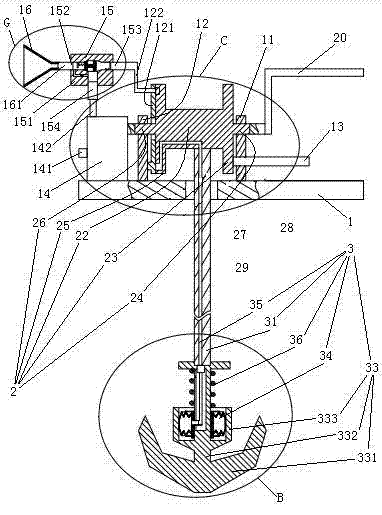

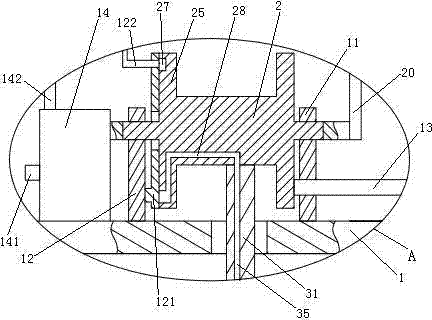

[0029] Embodiment one, see figure 1 , a ship mooring device, including a mounting seat 1, an anchor 3, a mechanical automatic transposition three-way valve 15 and a mooring suction cup 16.

[0030] The mounting base 1 is provided with a winding reel 2 , a right support frame 11 , a left support frame 12 and a two-way air pump 14 . The winding reel 2 includes a winding post 22 , a right baffle 23 , a right support shaft 24 , a left baffle 25 and a left support shaft 26 . The left side of the right baffle plate 23 and the right end of the coil post 22 are connected together. The right side of the right baffle plate 23 and the left end of the right supporting shaft 24 are connected together. The right support shaft 24 is rotatably supported on the right support frame 11 . The right end of the right supporting shaft 24 is provided with a rocking handle 20 . The right support frame 11 is detachably connected with a brake lever 13 . The right side of the left baffle plate 25 is...

Embodiment 2

[0041] Embodiment two, the difference with embodiment one is:

[0042] see Figure 6 , also includes a first connecting piece 4, a second connecting piece 5, a spare bolt storage clip 6, a spare nut storage clip 7 and a bolt and nut assembly mechanism.

[0043] The winding post 22 is a hollow structure. The winding post 22 is provided with an upper connection hole 21 .

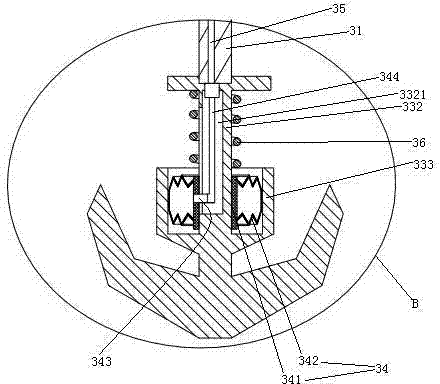

[0044] The anchor cable 31 is provided with a connecting seat 32 . The connecting base 32 defines a lower connecting hole 321 . The communication groove 27 passes through the trachea in the connecting pipe 29 and the anchor cable 31 (see figure 1 ) connectivity.

[0045] The first connecting piece 4 includes vertical bolts 41 and nuts 42 matched with the bolts. The connecting base 32 is suspended from the winding reel 2 through the first connecting piece 4 . The specific connection method is that the bolt 41 is screwed together with the nut 42 after passing through the upper connection hole and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com