Bottle cap component with material barrel arranged in cap

A technology for bottle caps and barrels, applied in the field of container caps, can solve problems such as unhygienic, inconvenient, and unsafe, and achieve the effects of saving space, convenient and fast use, and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

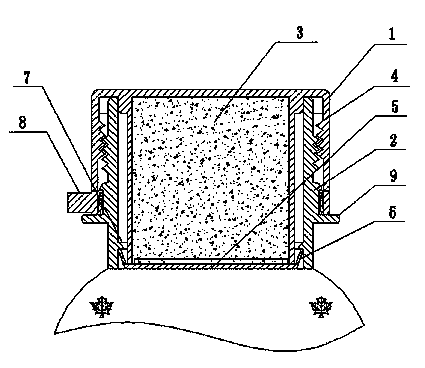

[0018] Such as figure 1 It is a structural diagram of an embodiment of the present invention. Since the focus of the present invention lies in the structure of the bottle mouth 2 and the bottle cap 1, there is no need to describe the bottle body. The bottle mouth 2 can be fixed with the bottle body in various ways. The prior art Some of them are directly formed, and some are fixed by hot-melt connection.

[0019] The inner side of the bottle cap 1 and the outer wall of the bottle mouth 2 are provided with threads 4 having the same specifications, and the bottle cap 1 and the bottle mouth 2 are connected by threads. It can be unscrewed and separated when in use, and it is tightened when it leaves the factory. Between the inner wall of the bottle cap 1 and the outer wall of the bottle mouth 2, except the threaded part, it is a sealing fit, which can also improve the sealing effect. There is a safety belt 8 on the lower part of the bottle cap, and a retaining edge 9 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com