Electric permanent magnetic chuck for conveyer belt

An electric permanent magnet suction cup and conveyor belt technology, applied in conveyors, transportation and packaging, etc., can solve the problems of power failure, loss of magnetism, heat generation, instability, etc., and achieve the effect of avoiding heat generation, avoiding safety accidents, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

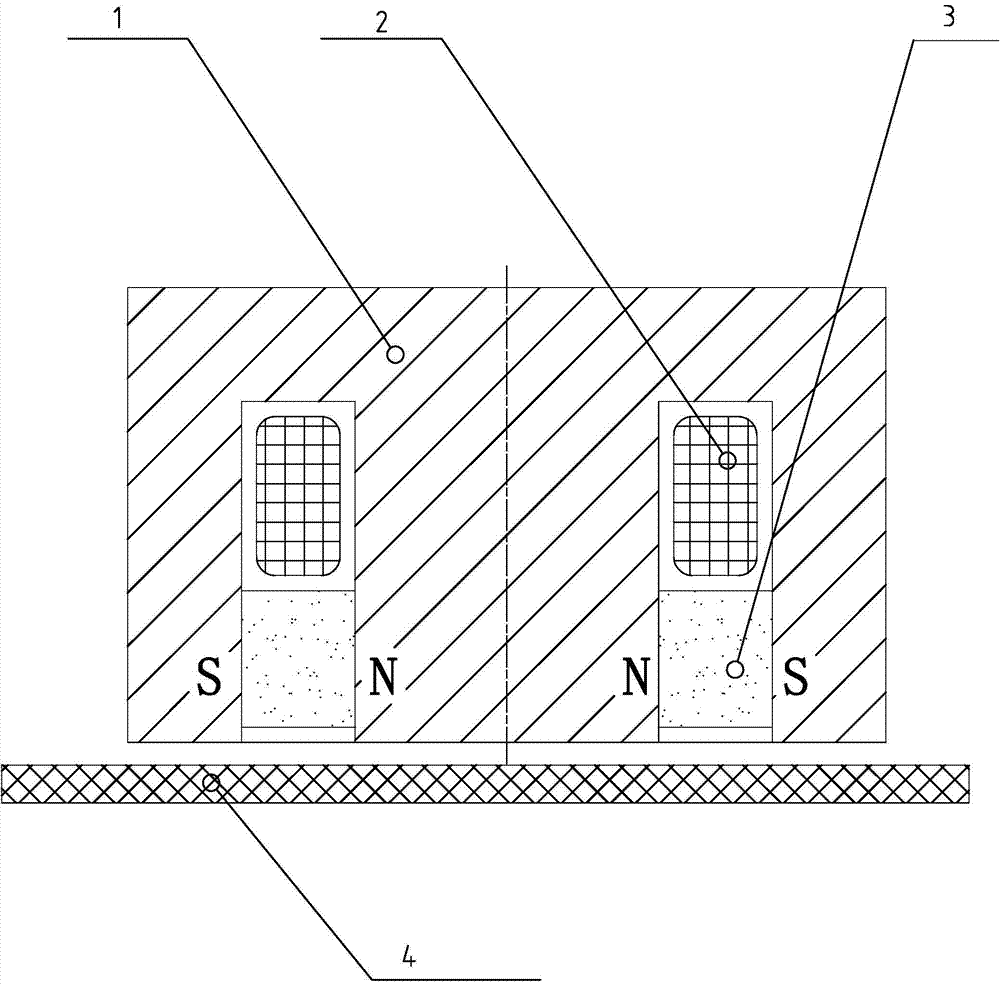

[0010] Such as figure 1 As shown, it includes a disc body 1 and a conveyor belt 4, and the disc body 1 is located above the conveyor belt 4; it also includes a coil 2 and a permanent magnet 3; the coil 2 and the permanent magnet 3 are arranged in the disc body 1; the permanent magnet 3 Located below coil 2.

[0011] The permanent magnet 3 is made of rare earth permanent magnet material; one end of the permanent magnet is an N pole; the other end is an S pole.

[0012] Working principle: Under normal conditions, the entire suction cup remains in a magnetic state, and the magnitude of the magnetic force is the magnetic force generated by the permanent magnet material passing through the disk body. The suction cup is installed at the position where the conveyor belt needs to absorb and release parts. When the parts move to these positions, the suction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com