A crane used for workpiece transportation and turnover

A technology of workpiece transportation and lifting frame, which is applied in transportation and packaging, vehicles with cranes, conveyors, etc., can solve the problems of complex equipment structure, cumulative displacement of hinge points, large swing amount, etc., to achieve automation, accurate positioning, The effect of less labor available for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

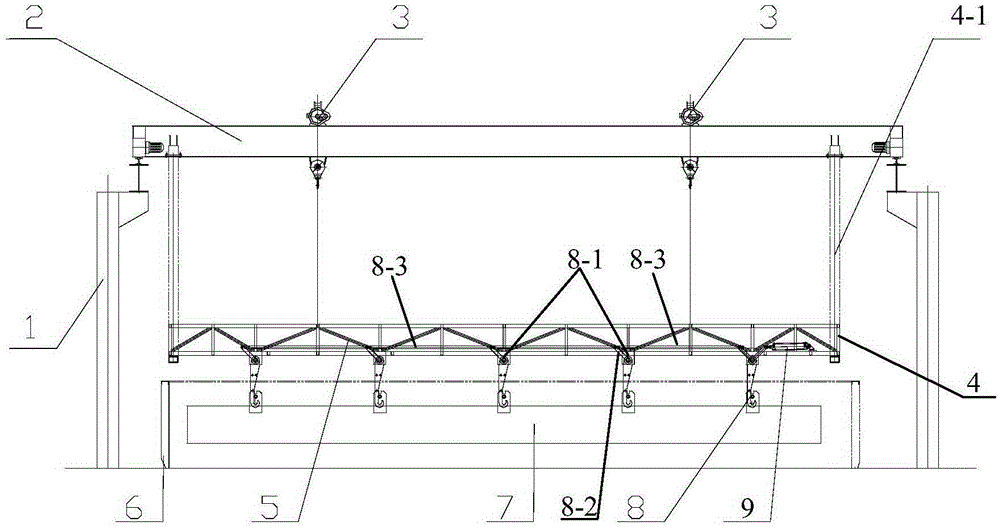

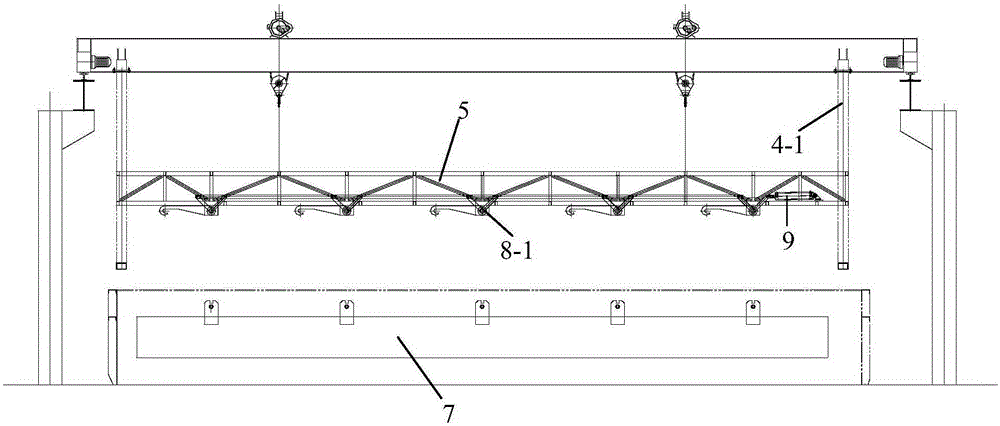

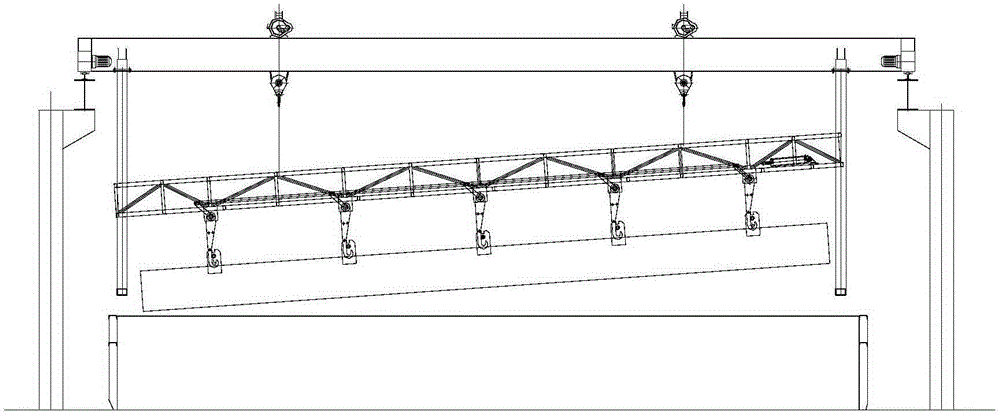

[0021] see Figure 1-4 , the driving device used for workpiece transportation and turnover in the present invention includes a driving column 1 arranged on both sides and a driving vehicle 2 installed on the driving column 1. It is characterized in that the horizontally arranged material Rack elevating frame 5 is provided with elevating guide mechanism 4 between driving 2 and material rack elevating frame 5.

[0022] The lifting guide mechanism 4 includes guide rails 4-1 vertically connected to both sides of the trolley 2, and sliders arranged at both ends of the lifting frame 5; the sliders cooperate with the guide rails 4-1.

[0023] The lifting frame 5 of the material rack is provided with several suspension hooks 8 arranged in a straight line, and the suspension hooks 8 are installed on the lifting frame 5 of the material rack through the rotating shaft 8-1. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com