Material for rapidly and effectively repairing pits in bituminous pavement and preparation method of material

An asphalt pavement and fast technology, applied in the field of building materials, can solve the problems of poor adhesion of the original pavement, poor performance of cementitious materials, insufficient pavement strength, etc., and achieve the effects of avoiding pavement diseases, uniform pavement and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh the cementitious material components according to the formula, 47% of petroleum asphalt, 5% of modifier, 10% of mineral powder, 3% of plasticizer, 10% of softening oil, 20% of waste rubber powder, and 5% of viscosity reducer;

[0038] Heat petroleum asphalt to 165-195°C to flow state, add softening oil and modifier for grinding for 30 minutes, then raise the temperature to 200-215°C, stir at 80-100r / min for 2 hours, cool down to 185-195°C and add Plasticizer and viscosity reducer, finally add waste rubber powder and mineral powder, stir for 1 hour and mix evenly to obtain cementitious material, its properties are shown in Table 1;

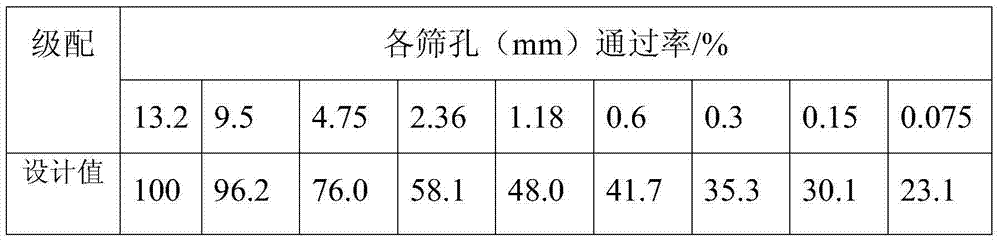

[0039] Add graded aggregate to the prepared cementing material, heat to 185-195°C and stir evenly. The weight percentage of cementing material and graded aggregate is 20% and 80%, and the composition of graded aggregate is:

[0040]

Embodiment 2

[0042] Weigh the cementitious material components according to the formula, 57% of petroleum asphalt, 3% of modifier, 8% of mineral powder, 2% of plasticizer, 10% of softening oil, 17% of waste rubber powder, and 3% of viscosity reducer;

[0043] Heat petroleum asphalt to 165-195°C to flow state, add softening oil and modifier for grinding for 30 minutes, then raise the temperature to 200-215°C, stir at 80-100r / min for 2 hours, cool down to 185-195°C and add Plasticizer and viscosity reducer, finally add waste rubber powder and mineral powder, stir for 1 hour and mix evenly to obtain cementitious material, its properties are shown in Table 1;

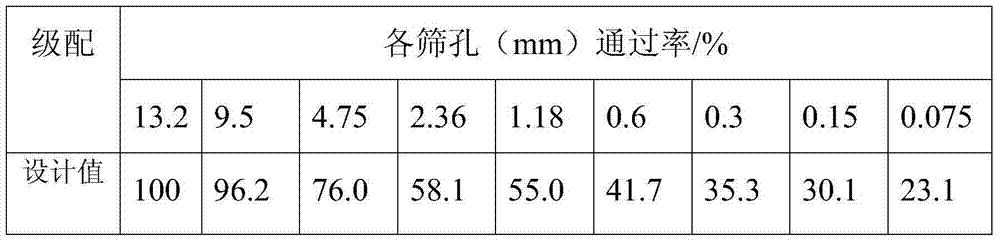

[0044] Add graded aggregate to the prepared cement, heat to 185-195°C and stir evenly. The weight percentages of adhesive and graded aggregate are 18% and 82%, and the composition of graded aggregate is:

[0045]

Embodiment 3

[0047] Weigh the cementitious material components according to the formula, 63% of petroleum asphalt, 5% of modifier, 9% of mineral powder, 1% of plasticizer, 8% of softening oil, 10% of waste rubber powder, and 4% of viscosity reducer;

[0048] Heat petroleum asphalt to 165-195°C to flow state, add softening oil and modifier for grinding for 30 minutes, then raise the temperature to 200-215°C, stir at 80-100r / min for 2 hours, cool down to 185-195°C and add Plasticizer and viscosity reducer, finally add waste rubber powder and mineral powder, stir for 1 hour and mix evenly to obtain cementitious material, its properties are shown in Table 1;

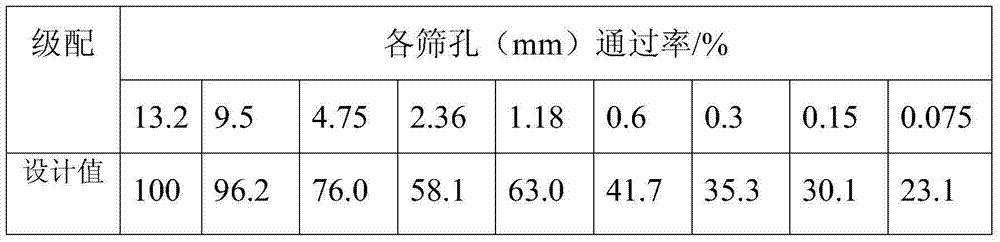

[0049] Add graded aggregate to the prepared cement, heat to 185-195°C and stir evenly. The weight percentages of adhesive and graded aggregate are 16% and 84%, and the composition of graded aggregate is:

[0050]

[0051] Table 1: Measured technical indicators of cementitious materials

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com