System and method for isolating voltage sensor faults, contactor faults in electrical systems

A technology of voltage sensor and contactor, applied in the direction of measuring current/voltage, instrument, measuring electricity, etc., can solve the problems of complicated diagnosis and isolation, failure of voltage sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

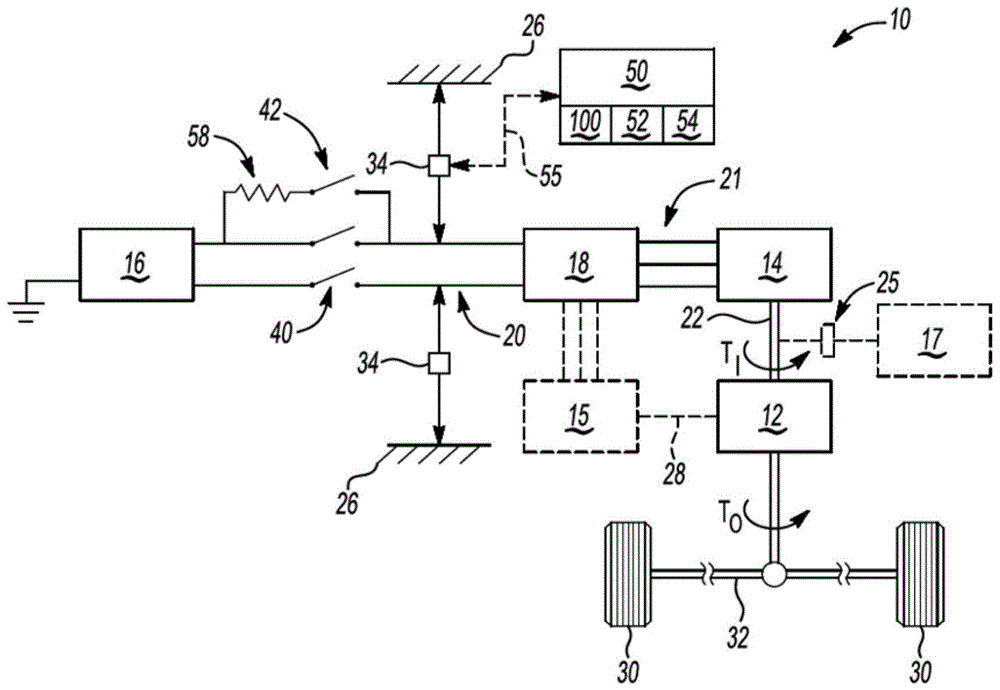

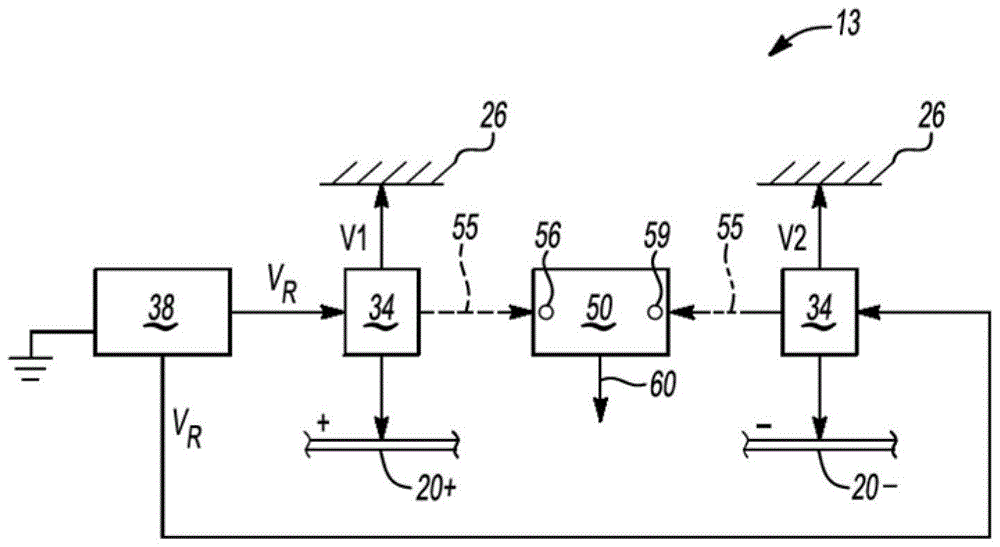

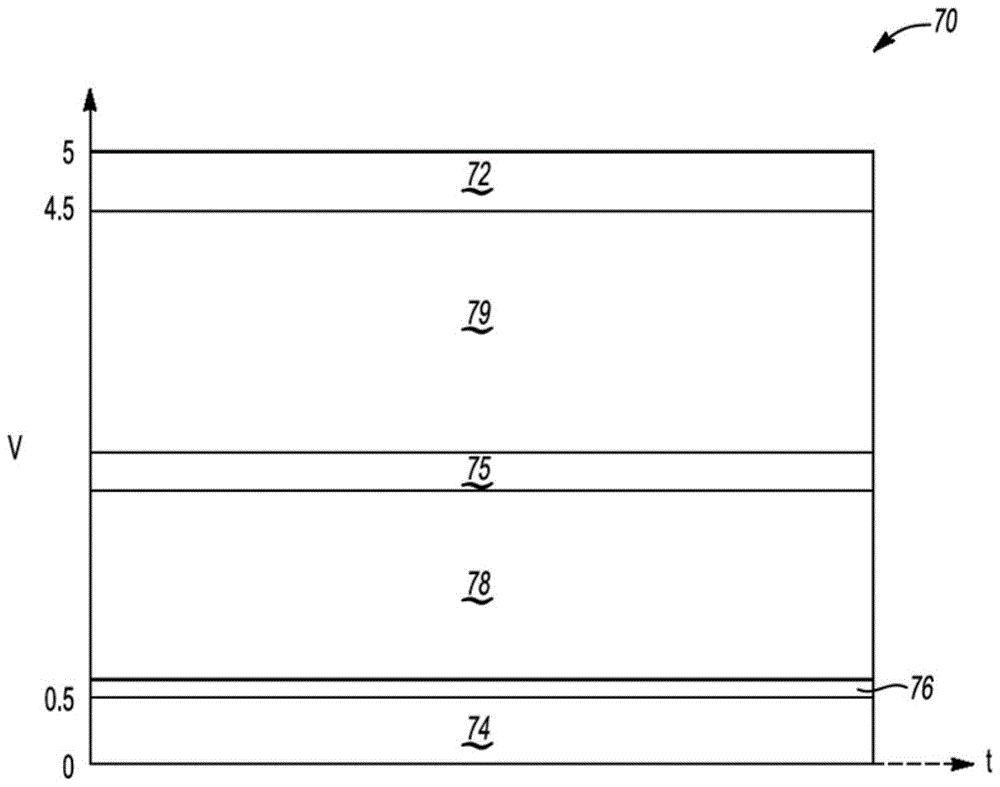

[0016] Referring to the drawings, in which like reference numerals refer to like parts, and with figure 1 Initially, an exemplary vehicle 10 is shown including a voltage source in the form of a battery pack 16 , a voltage sensor 34 , a set of solid state contactors 40 and a controller 50 . see below Figure 2-4 Described in detail, the control 50 is configured to selectively perform the steps of the method 100 to isolate high voltage electrical faults on the vehicle 10, specifically a "stuck in range" fault of the voltage sensor 34 and a "bonded closed" of the contactor 40 Fault. The method 100 can be used in any electrical system that employs a voltage source, be it a battery, fuel cell, capacitor, or other electrical or chemical voltage source, via a mechanical / solid state switch, relay, or The contactor 40 is disconnected from the electrical load by actuation of the similar contactor. However, for consistency of description, the exemplary vehicle 10 will be described in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com