A development method of additional axis function of industrial robot

A technology of industrial robots and additional axes, which is applied in the direction of instruments, simulators, control/regulation systems, etc., can solve the problems of robot manufacturers such as less development time, poor software consistency, and short delivery cycle, so as to shorten delivery time, The effect of small modification and no need for repeated development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

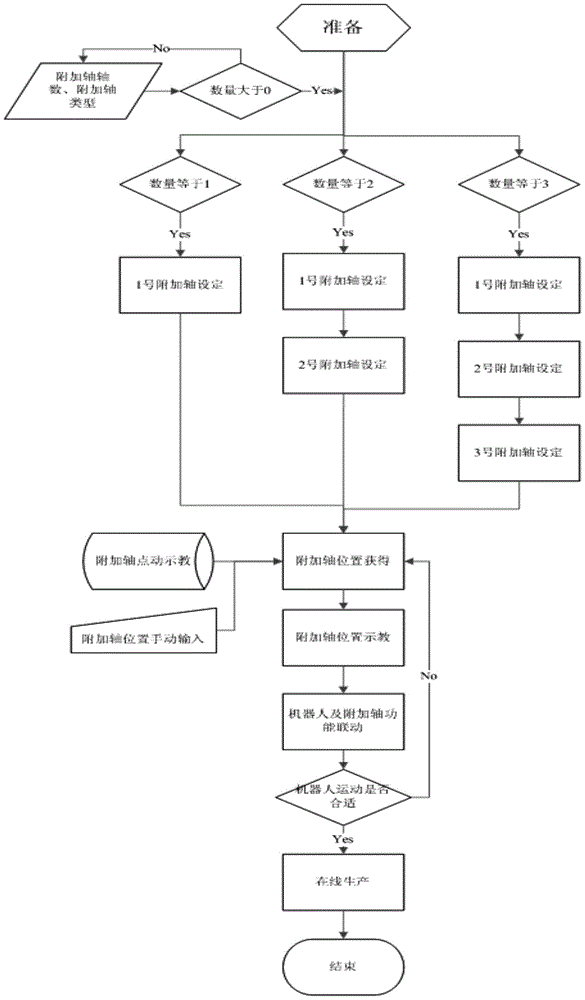

Method used

Image

Examples

Embodiment Construction

[0015] According to the long-term investigation results of the field application of the additional axis, the additional axis can generally be divided into the following three types: 1. Simple type: independent from the robot, and its typical application is the function of the servo welding gun; 2. Robot type: form a whole together with the robot, Its typical application is a sliding guide rail; 3. External type: the trajectory of the robot is affected by an external additional axis, and its typical application is a positioner.

[0016] According to the application of the additional shaft, the present invention develops and tests the functions of the above three types of additional shafts in advance. Firstly, during the development of software functions, a virtual axis (the virtual axis has the characteristics of a real axis) is established to meet the development and testing of software functions, thereby reducing the software development and testing time after the end customer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com