Intelligent self-learning system for electromechanical equipment

A kind of electromechanical equipment and self-learning technology, which is applied in the general control system, control/regulation system, test/monitoring control system, etc., can solve the problems that the operating parameters are difficult to pre-set accurately and the phenomenon cannot be reproduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

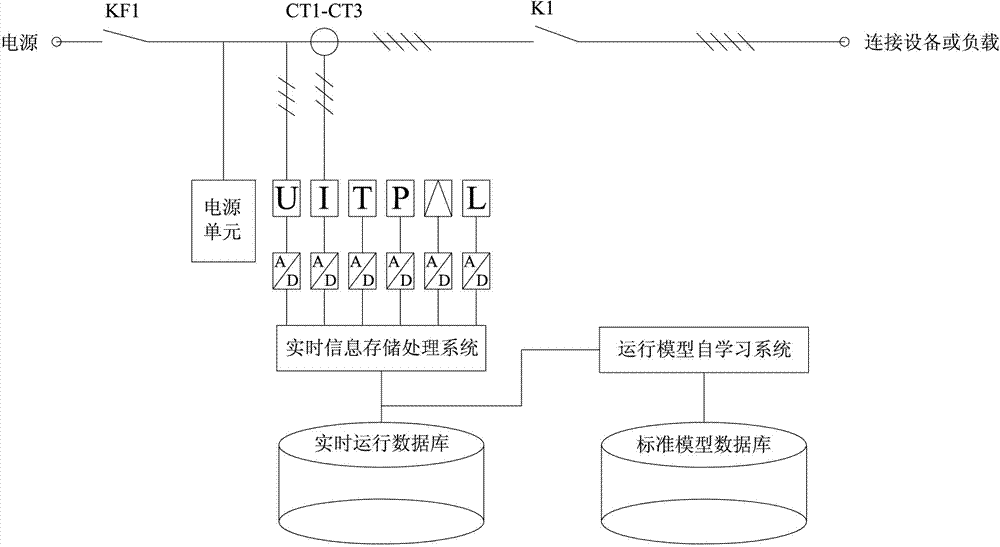

[0028] Embodiment one: see attached figure 1 shown.

[0029] An intelligent self-learning system for electromechanical equipment connected with electromechanical equipment and used for assisting in analyzing the operation of the electromechanical equipment includes a data acquisition unit, an operation model self-learning system and a standard model database.

[0030] The data acquisition unit is connected with the electromechanical equipment and used for real-time acquisition of multiple parameters in the operation of the electromechanical equipment.

[0031] Specifically, the data acquisition unit includes connecting wires, current transformers CT1-CT3, voltage transmitter U, current transmitter I, temperature sensor T, pressure sensor P, arc detector Λ, logic signal collector L, multiple A / D converter, real-time information storage and processing system, real-time operation database and power supply unit.

[0032] The connecting wire is connected between the power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com