overcurrent protection element

一种保护元件、过电流的技术,应用在电流响应的电阻器、具有正温度系数的电阻器等方向,达到提升生产速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the above-mentioned and other technical contents, features and advantages of the present invention more obvious and understandable, the relevant embodiments are specifically listed below, and are described in detail as follows in conjunction with the accompanying drawings:

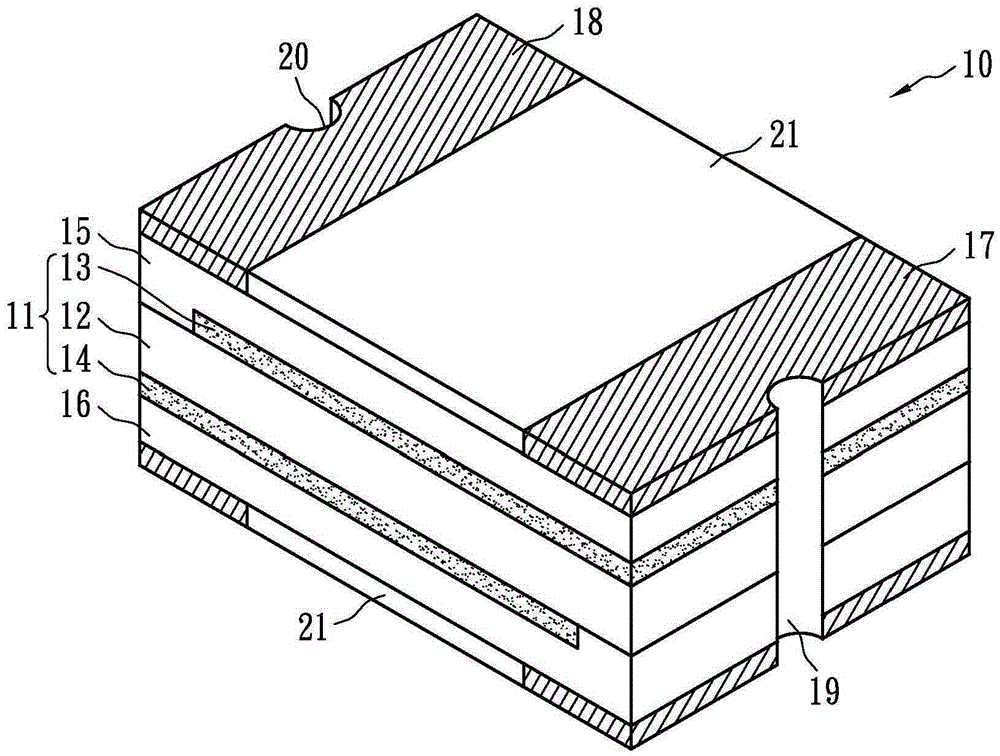

[0052] Figure 4A It is a three-dimensional structural diagram of an overcurrent protection element according to an embodiment of the present invention. The overcurrent protection element 40 is approximately a rectangular parallelepiped with opposite upper surfaces, lower surfaces and four side surfaces. The four side surfaces connect the upper surface and the lower surface, and adjacent side surfaces form four corners. The overcurrent protection element 40 includes: a PTC material layer 41, a first conductive layer 42, a second conductive layer 43, a first insulating layer 44, a second insulating layer 45, a first electrode layer 46, a second electrode layer 47 and four A conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com