Power distribution cabinet

A technology for power distribution cabinets and cabinets, applied in the field of power distribution cabinets for EMUs, can solve the problems of large deformation of the cabinets, residual stress, poor aesthetics, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A power distribution cabinet of the present invention includes a main skeleton structure, a transition skeleton structure, and an auxiliary skeleton structure, and the main skeleton structure, the transition skeleton structure and the auxiliary skeleton structure are riveted with rivets.

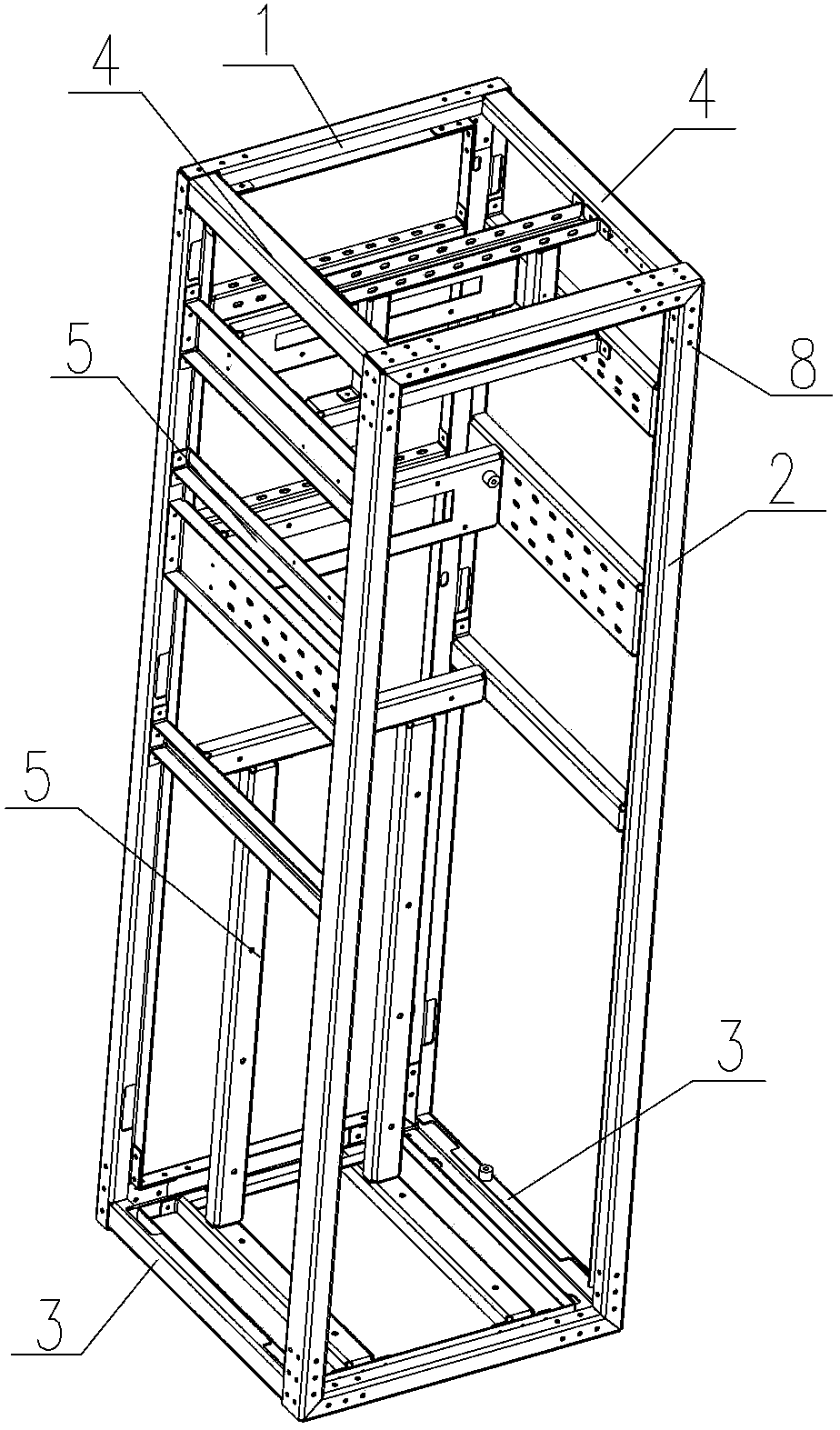

[0025] Such as figure 1 As shown, the main skeleton structure plays the main supporting role, including the front skeleton frame 2 located at the front side of the power distribution cabinet, and the rear skeleton frame 1 located at the rear side of the power distribution cabinet. The front skeleton frame 2 is mouth-shaped, and the rear skeleton frame 1 is also mouth-shaped. . The front skeleton frame 2 and the rear skeleton frame 1 are spliced by four frames, which makes the assembly easier and more convenient, and can improve the versatility of the overall frame structure of the power distribution cabinet.

[0026] The transition skeleton structure acts as a connection, consistin...

Embodiment 2

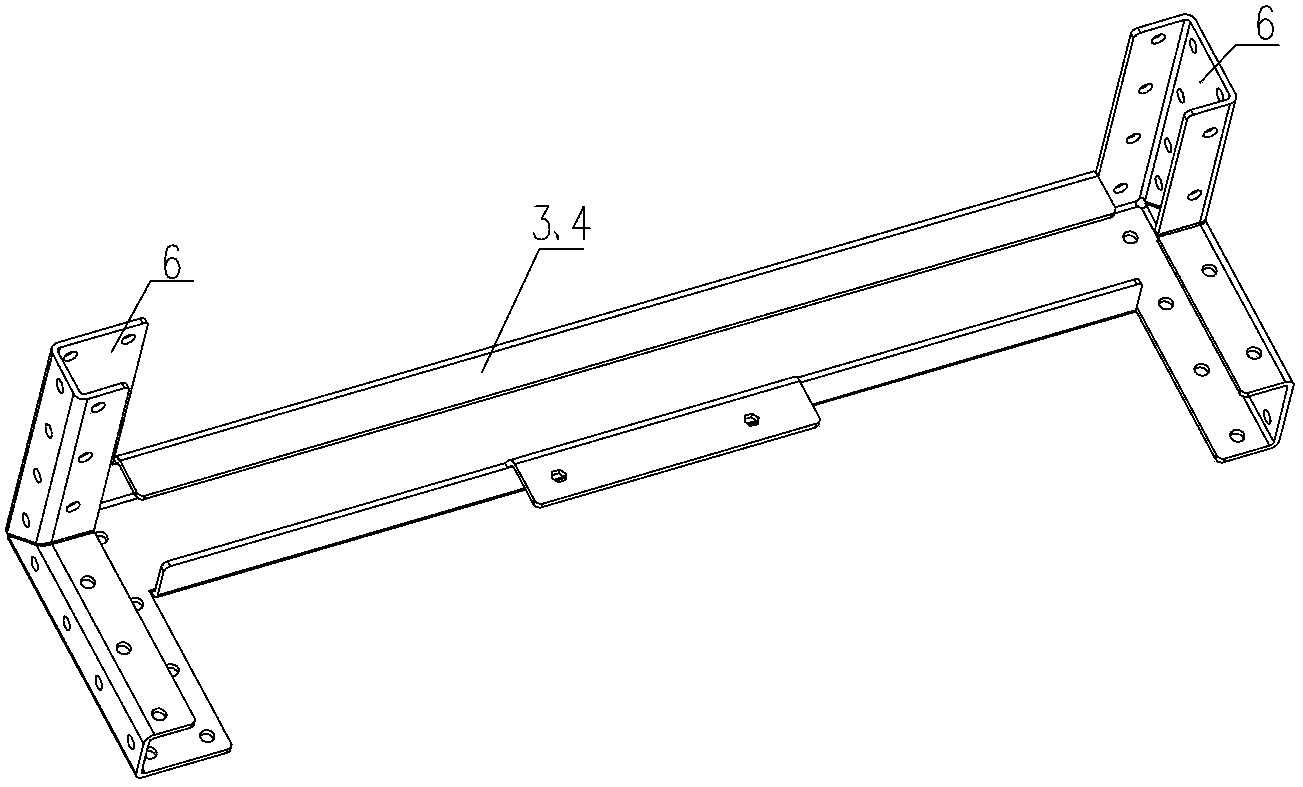

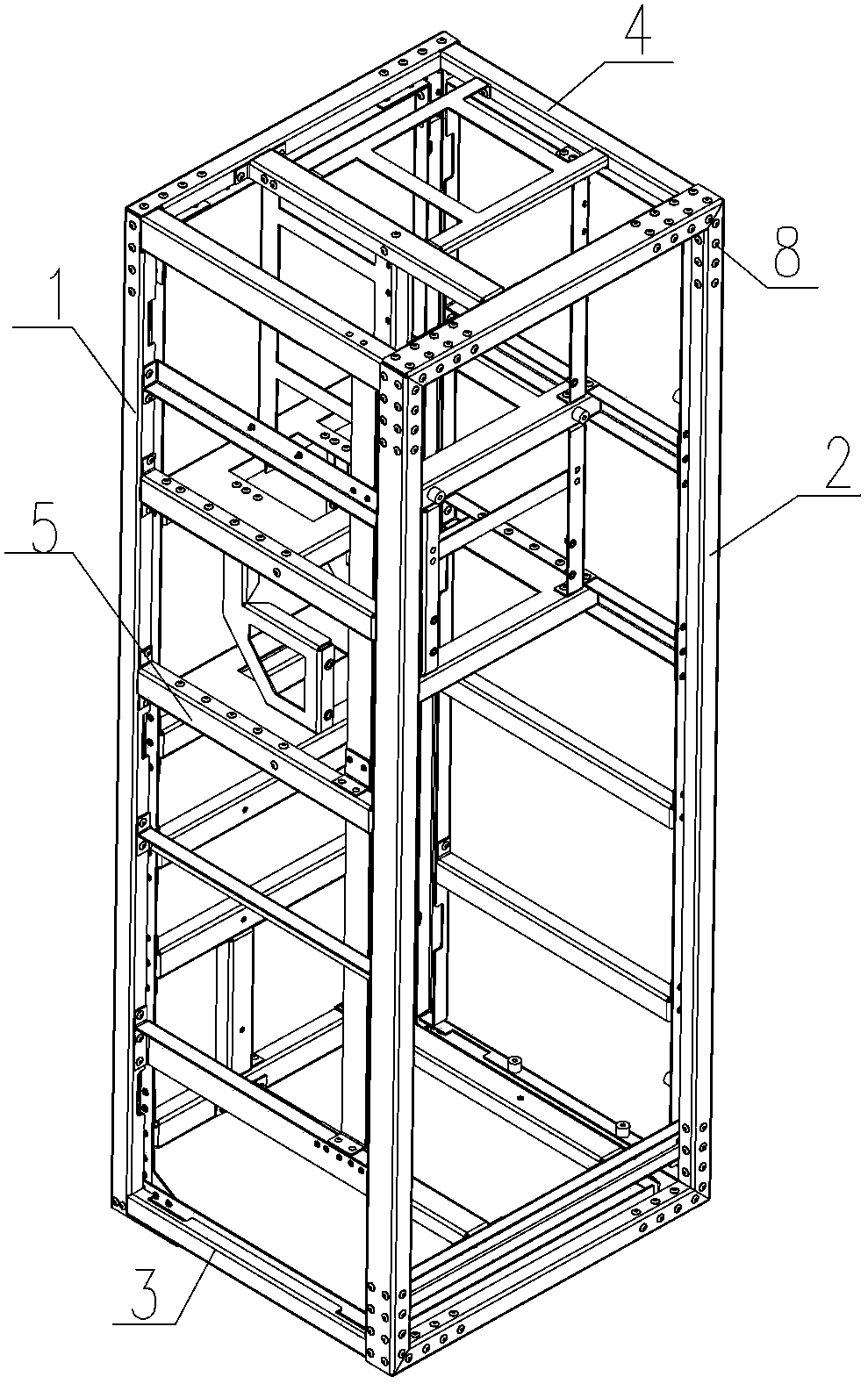

[0031] Such as image 3 As shown, for wiring or structural needs, the rear skeleton frame 1 adopts a door-shaped structure, the rear skeleton frame 1 has no bottom frame, and the upper transition skeleton 4 is as figure 2 Both ends shown are provided with corner structures 6, and the lower transition frame 3 is as Figure 4 As shown, the corner structure 6 is only provided at one end, and the corner structure 6 is not provided at the other end.

[0032] The two upper transition frames 4 and the two lower transition frames 3 are riveted and spliced together by riveting the four frames of the front frame frame 2 and the rear frame frame 1 by means of corner structures 6 or directly fixed at the ends, and then forming a A mouth-shaped front skeleton frame 2 and a door-shaped rear skeleton frame 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com