Stepped piezoelectric generator

A generator, stepped technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of low power generation efficiency, low power generation efficiency of piezoelectric crystal, and inability to Fully meet the needs of use and other issues, and achieve the effects of good practicability, improved power generation efficiency and working life, good economic benefits and social effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further clarified below in conjunction with specific drawings. This specific embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these modes are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

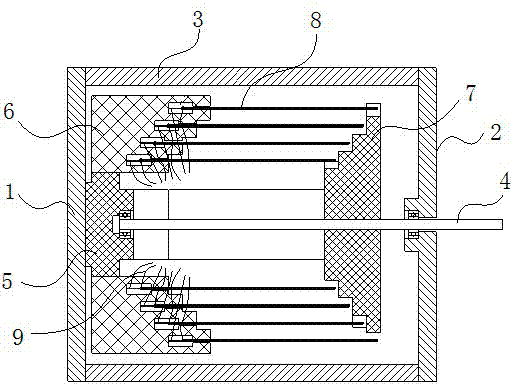

[0016] like figure 1 As shown, the main structural components of the stepped piezoelectric generator include a first end cover 1, a second end cover 2, a cylinder body 3, a shaft 4, a shaft base 5, a stepped fixed piezoelectric ceramic bimorph base 6, a rotating Step cam 7, piezoelectric ceramic bimorph 8 and lead wire 9. The first end cover 1 and the second end cover 2 are respectively arranged at the corresponding two ends of the cylinder body 3, and are jointly combined into a generator body; a shaft base 5 is arranged at the bottom of the generator body, and one end of the shaft 4 is connected to the shaft base 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com