Use of a hypoallergenic cereal composition for inducing specific oral tolerance

A specific, grain-based technology that can be used in drug combinations, medical preparations containing active ingredients, allergic diseases, etc., and can solve problems such as allergies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

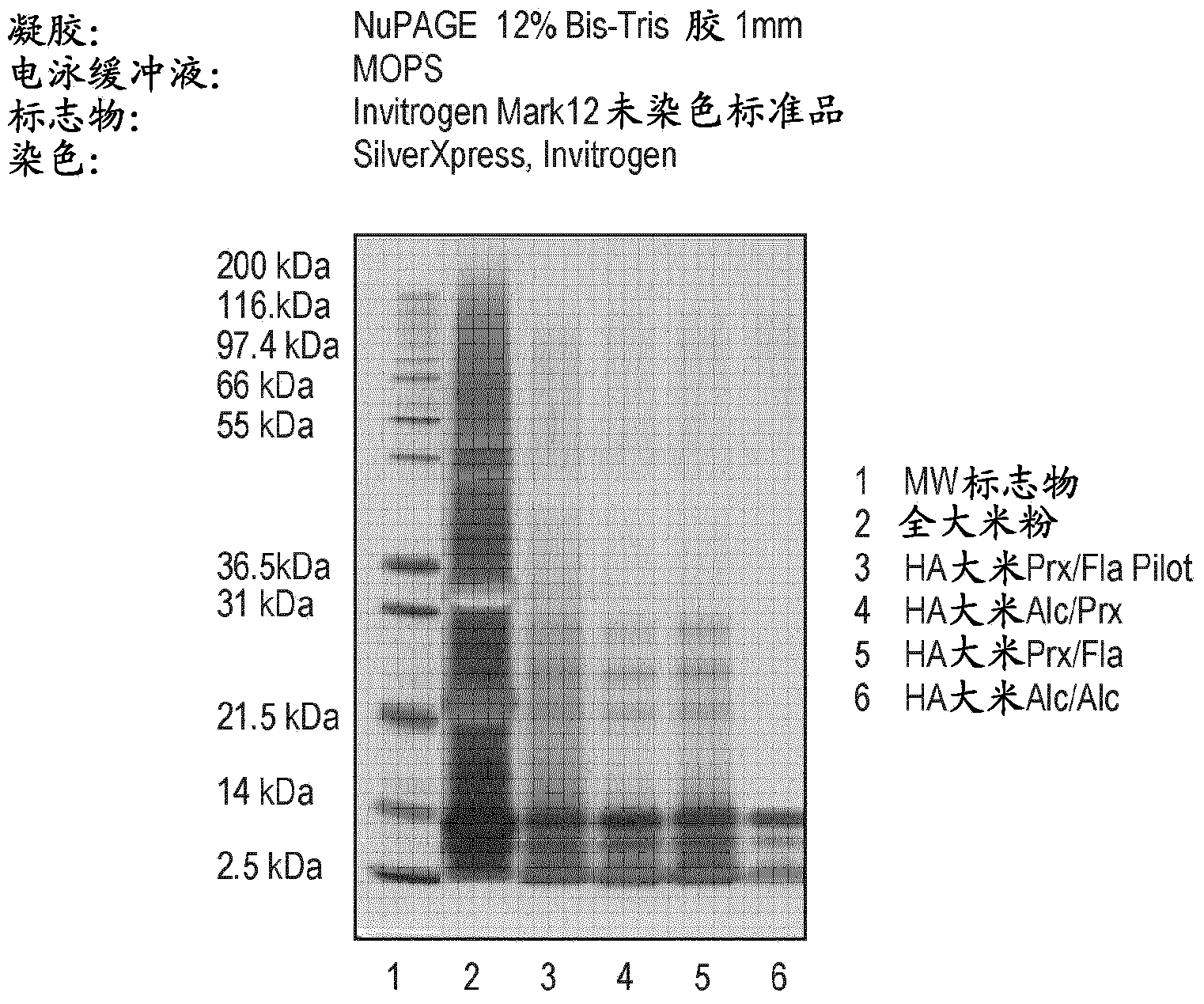

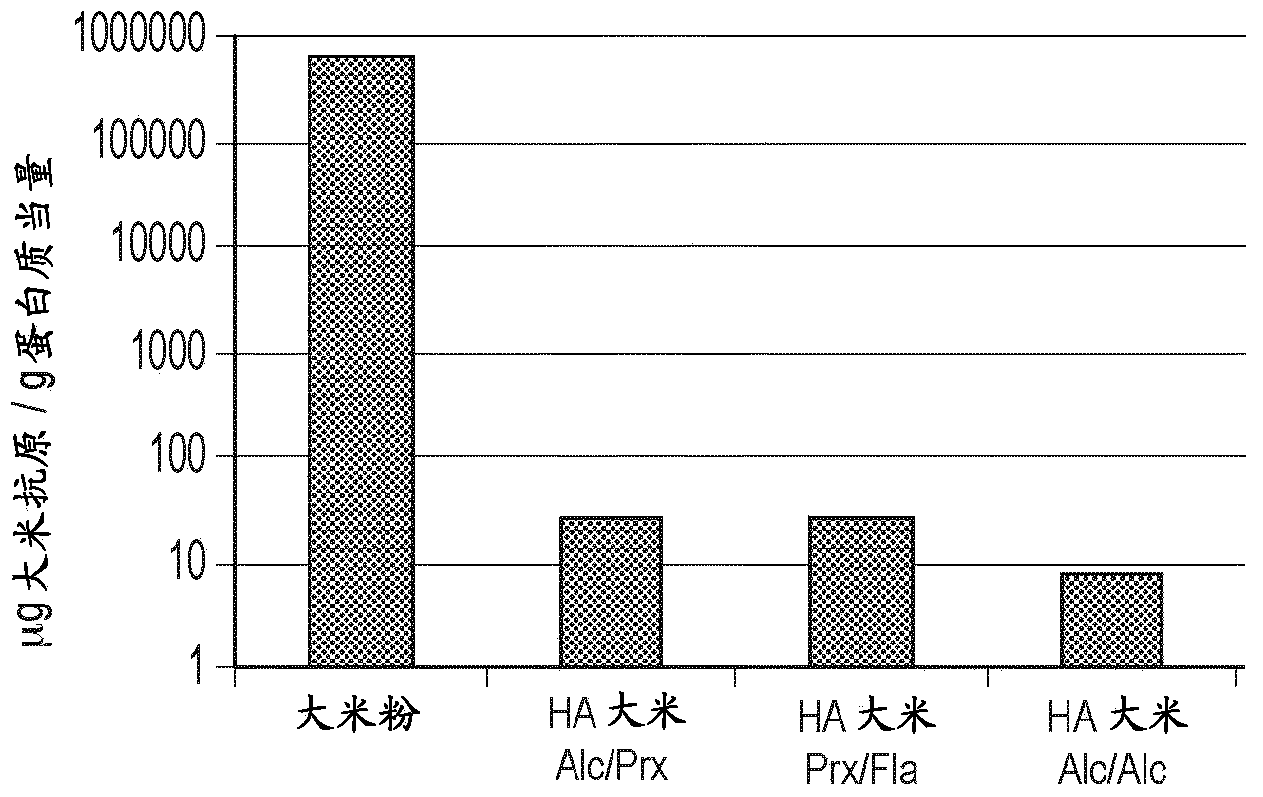

Embodiment 1

[0071] 10 Kg of rice flour (pretreated according to US Patent No. 4,374,860 to partially hydrolyze the carbohydrate content) and 23 kg of water were mixed and heated at 55°C. Prepare buffer solution (Na(OH) 2 or K(OH) 2 or Ca(OH) 2 ), added to the mixture for pH adjustment. Add 5% Enzyme (Lot No. PW2A1006, Novozymes A / S Bagsvaerd, Denmark), the mixture was maintained at 55°C for 2 hours. After completion of this first hydrolysis step, the mixture was heated at 90° C. for 10 minutes. Cool the mixture to 55°C, add 5% 1000 L of enzyme (Lot No. 400904, Novozymes A / S Bagsvaerd, Denmark), the mixture was maintained at 55°C for 2 hours. After this second step of hydrolysis, the mixture was heated at 90°C for 30 minutes, followed by spray drying to obtain a powder containing partially hydrolyzed rice protein with a DH of 14.2%, which was placed in an aluminum bag.

Embodiment 2

[0073] 10 Kg of rice flour (pretreated according to US Patent No. 4,374,860 to partially hydrolyze the carbohydrate content) and 23 kg of water were mixed and heated at 55°C. Prepare buffer solution (Na(OH) 2 or K(OH) 2 or Ca(OH) 2 ), the mixture was added for pH adjustment (to pH 7.8). Add 10% of Enzyme (Lot No. 500357, Novozymes A / S Bagsvaerd, Denmark), the mixture was maintained at 55°C for 2 hours. After completion of this first hydrolysis step, the mixture was heated at 90° C. for 10 minutes. The mixture was cooled to 55°C, 10% Alcalase enzyme was added, and the mixture was maintained at 55°C for 2 hours. After this second step of hydrolysis, the mixture was heated at 90°C for 30 minutes, followed by spray drying to obtain a powder containing partially hydrolyzed rice protein with a DH of 15.9%, which was placed in an aluminum bag.

Embodiment 3

[0075]10 Kg of rice flour (pretreated according to US Patent 4,374,860 to partially hydrolyze the carbohydrate content) and 23 kg of water were mixed and heated at 55°C. Prepare buffer solution (Na(OH) 2 or K(OH) 2 or Ca(OH) 2 ), the mixture was added for pH adjustment (to pH 7.8). Add 5% Enzyme (Lot No. 500357, Novozymes A / S Bagsvaerd, Denmark), the mixture was maintained at 55°C for 2 hours. After completion of this first hydrolysis step, the mixture was heated at 90° C. for 10 minutes. Cool the mixture to 55°C, add 5% Enzyme (Lot No. PW2A1006, Novozymes A / S Bagsvaerd, Denmark), the mixture was maintained at 55°C for 2 hours. After this second step of hydrolysis, the mixture was heated at 90 °C for 30 minutes, followed by spray drying to obtain a powder containing partially hydrolyzed rice protein with a DH of 11.2%, which was placed in an aluminum bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com