Automatic paper paving device

A paper laying and automatic technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of unguaranteed laying quality and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

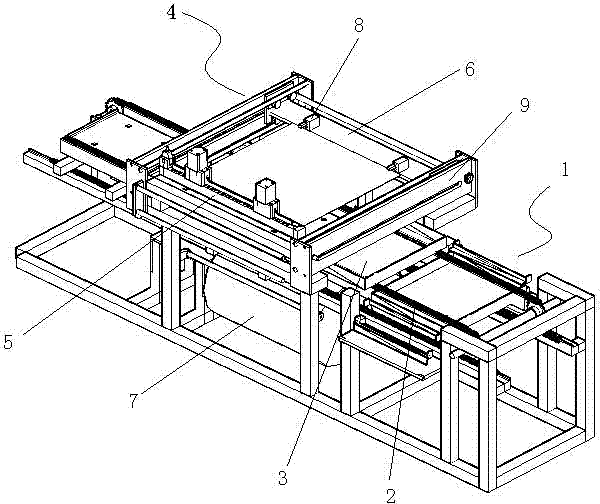

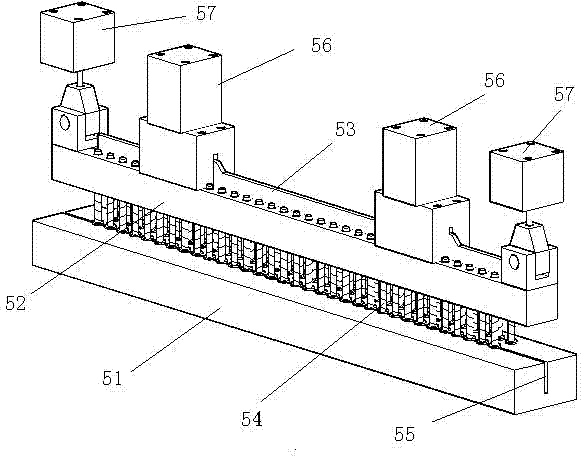

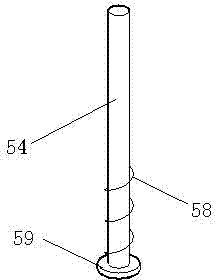

[0019] Such as Figure 1-Figure 3 As shown, an automatic paper-laying device includes a frame 1 and a conveyor belt 2 arranged on the frame 1 for conveying the mold plate 3, a paper-laying mechanism 4 is arranged above the conveyor belt 2, and the paper-laying A sheet stock paper roll 7 is arranged below the conveyor belt 2 at the mechanism 4, and a cutting mechanism 5 is provided on a side of the sheet laying mechanism 4 close to the sheet stock paper roll 7, and the paper laying mechanism 4 is far away from the sheet stock paper roll 7. One side is provided with movable manipulator 8.

[0020] When the conveyor belt 2 transports the template 3 to the bottom of the paper laying mechanism 4, the manipulator 8 moves forward, clamps the sheet paper and then pulls it back. After it is reset, the cutting mechanism 5 cuts the sheet paper and makes the sheet The paper is c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap