Water heating blanket and production process thereof

A technology for making crafts and plumbing blankets, applied to carpets, etc., can solve problems such as complicated installation, difficult maintenance, and difficult movement, and achieve the effects of simple maintenance, high safety, and easy manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

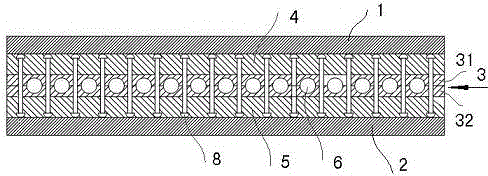

[0058] Example 1: Such as figure 1 As shown, a plumbing blanket includes an upper surface layer 1 and a lower surface layer 2. The central part of the plumbing blanket has a heating layer 3, the upper surface of the heating layer 3 is connected with the upper reinforcement layer 4, and the upper surface of the upper reinforcement layer 4 is connected to the upper surface Layer 1 is connected; the underside of the heating layer 3 is connected with the lower reinforcement layer 5, and the underside of the lower reinforcement layer 5 is connected with the lower surface layer 2. The heating layer 3 is composed of an upper plastic layer 31 and a lower plastic layer 32. The upper plastic layer 31 and the lower The plastic layer 32 is formed into an integral structure by hot pressing. A hot water pipe network 6 is provided between the upper plastic layer 31 and the lower plastic layer 32. The two ends of the hot water pipe network 6 are connected with pipe joints 7; The surface layer 2...

Embodiment 2

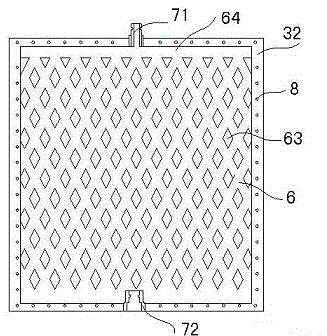

[0062] Example 2: The overall structure of the hot water pipe network is that the water channels are in a mesh structure, and the mesh of the mesh structure is in a rhombus shape 63. The rhombus shape 63 facilitates the mixing of hot water with different water temperatures, and the water temperature is overall balanced. The water-passing time is short, which is suitable for applications where the plumbing blanket has a large laying area and the unit plumbing blankets are connected in series; each branch pipe of the hot water pipe network is connected with a current equalizing main pipe 64, and the current equalizing main pipe 64 is connected with a pipe joint. The rest of the structure is the same as in embodiment 1, such as image 3 Shown. The pipe joint is a plug-in structure, image 3 The male plug 71 and the female plug 72 in the middle are matched, and are in a position where the upper and lower sides are aligned in the center.

Embodiment 3

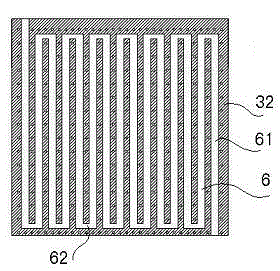

[0063] Embodiment 3: The overall structure of the hot water pipe network is that in the middle of the heating layer, there are a batch of parallel straight water channels, and all the parallel straight water channels are connected in parallel and connected to the pipe joint 7 through the equalizing main pipe 64. The pipe joint can be made into a plug-in type, and the pipe joint is equipped with a sealing device for easy installation. The rest of the structure is the same as in embodiment 1, such as Figure 4 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com