Pigging ball filling base

A pigging ball and filling technology, which is applied in the field of offshore petroleum engineering, can solve the problems of increasing the thrust of the pigging ball, troublesome filling operations, and skewing the pigging ball, and achieves a stable, easy operation, time-saving and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

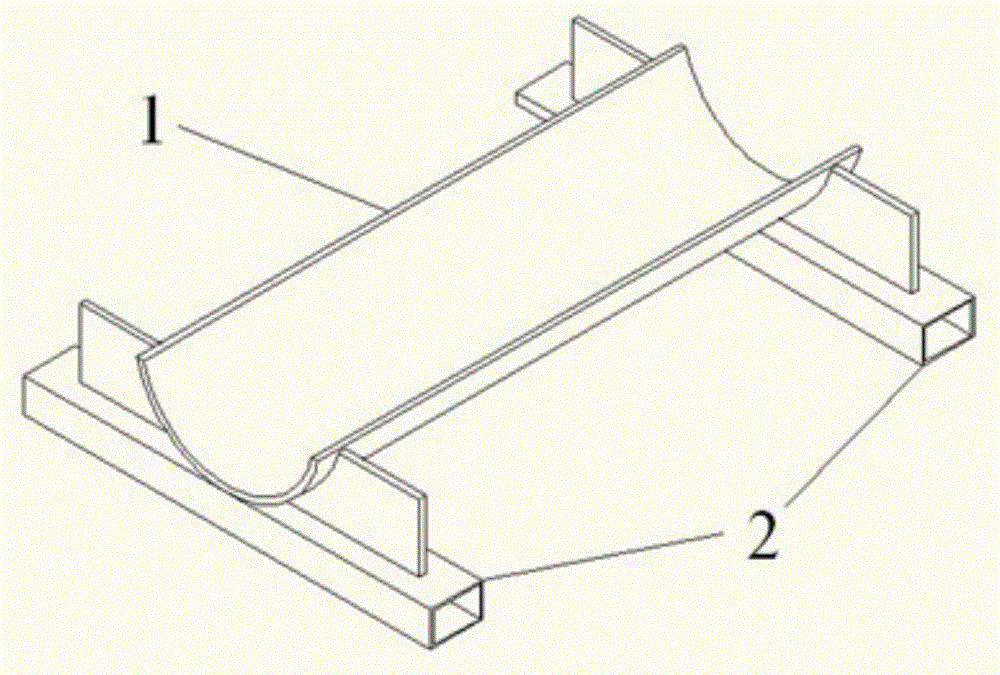

[0015] Such as figure 1 As shown, the present invention is provided with: an arc plate 1, the two ends of the bottom of the arc plate 1 are respectively equipped with a base support 2 in a welding manner, wherein the arc plate 1 is made of steel pipes, and the arc of the arc plate 1 is in line with the pigging The arcs of the balls 3 coincide; and the length of the arc plate 1 is greater than the length of the pigging ball 3; the radius of the arc plate 1 is slightly greater than the radius of the pigging ball rubber plate 31.

[0016] The base bracket 2 is: composed of a rectangular pipe and a steel plate installed vertically on the rectangular pipe by welding. The middle part of the steel plate is provided with an arc groove matching the arc of the arc plate 1 .

[0017] The bottom pad of above-mentioned base support 2 is placed with the backing plate of adjusting height.

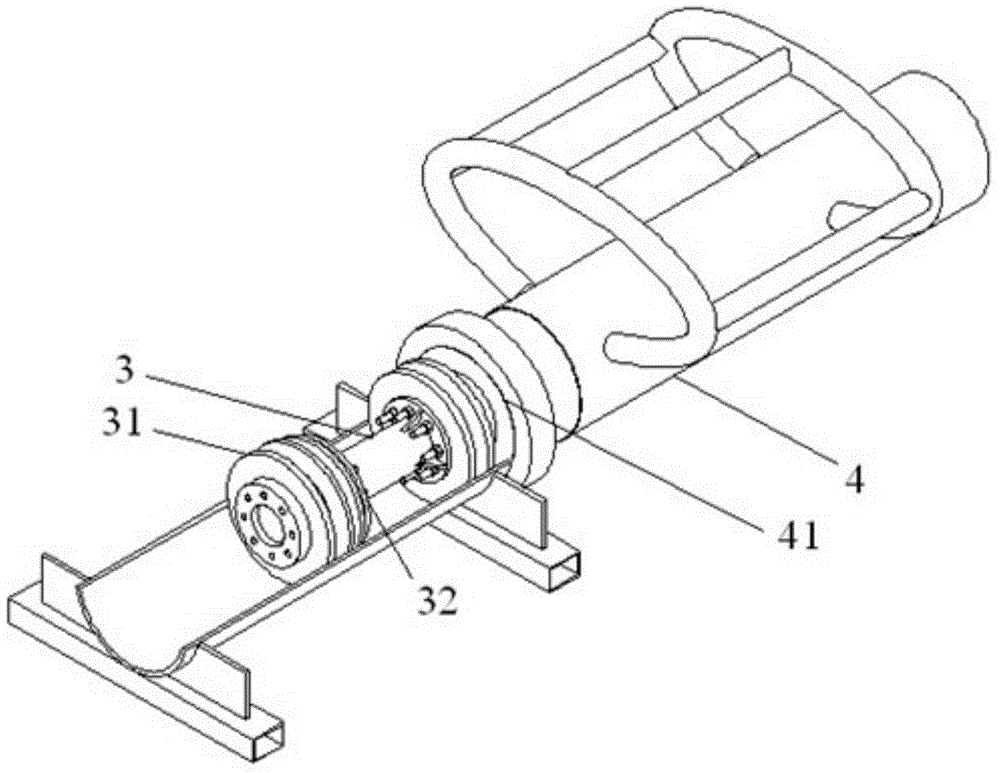

[0018] Such as figure 2 As shown, when in use, the serving tube 4 is bound and fixed, and the after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com