Auxiliary clamping device with two positioning modes for turning process of steam turbine rotors

A steam turbine rotor and auxiliary clamping technology, which is used in positioning devices, turning equipment, metal processing equipment, etc., can solve the problems of small diameter adjustment, easy deformation, clamping of horizontal lathe chucks, etc. Easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

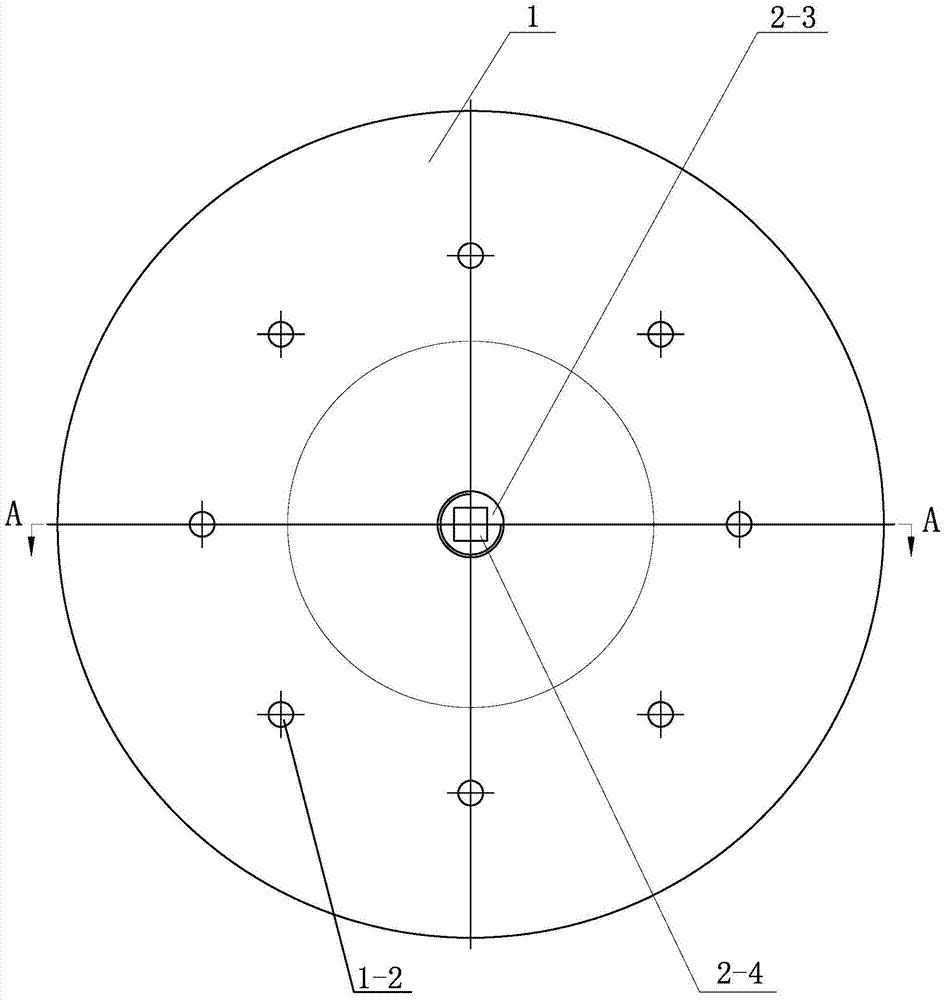

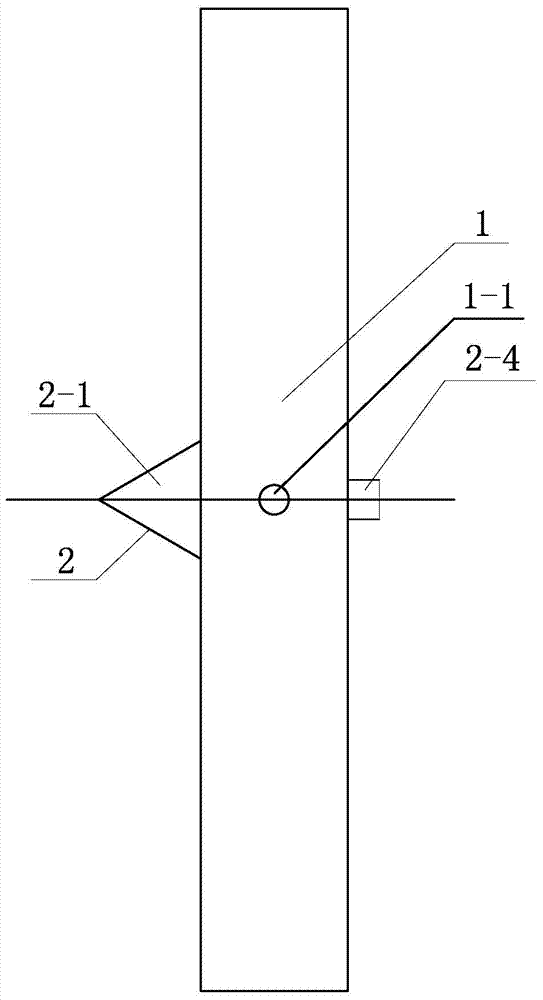

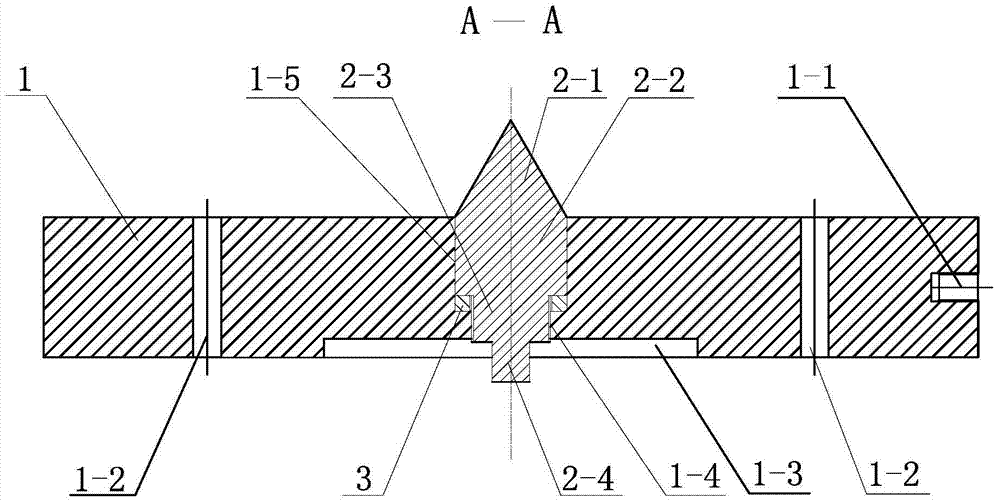

[0008] Specific implementation mode one: combine Figure 1-Figure 4 Explanation; the auxiliary clamping device for turning of steam turbine rotor with two positioning methods in this embodiment, the auxiliary clamping device for turning of steam turbine rotor with two positioning methods includes a disc 1, a positioning member 2 and a sleeve 3, The center of the end surface on one side of the disc 1 is coaxially provided with a concave stop 1-3 (counterbore) and a first threaded hole 1-4 from the outside to the inside, and a concave hole 1-4 is provided at the center of the end surface of the other side of the disc 1. The pin hole 1-5 connected with the seam 1-3 and the first threaded hole 1-4, the disc 1 is located on the same circumference and is uniformly processed with a plurality of through holes 1-2 penetrating the thickness of the disc 1, the disc 1 1. A second threaded hole 1-1 is processed radially on the outer peripheral surface. The positioning member 2 includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com