Injection molding method for inserting glass into mold and product thereof

A technology of injection molding and inserting, which can be applied to household appliances, other household appliances, household components, etc., and can solve the problems of ordinary glass being easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

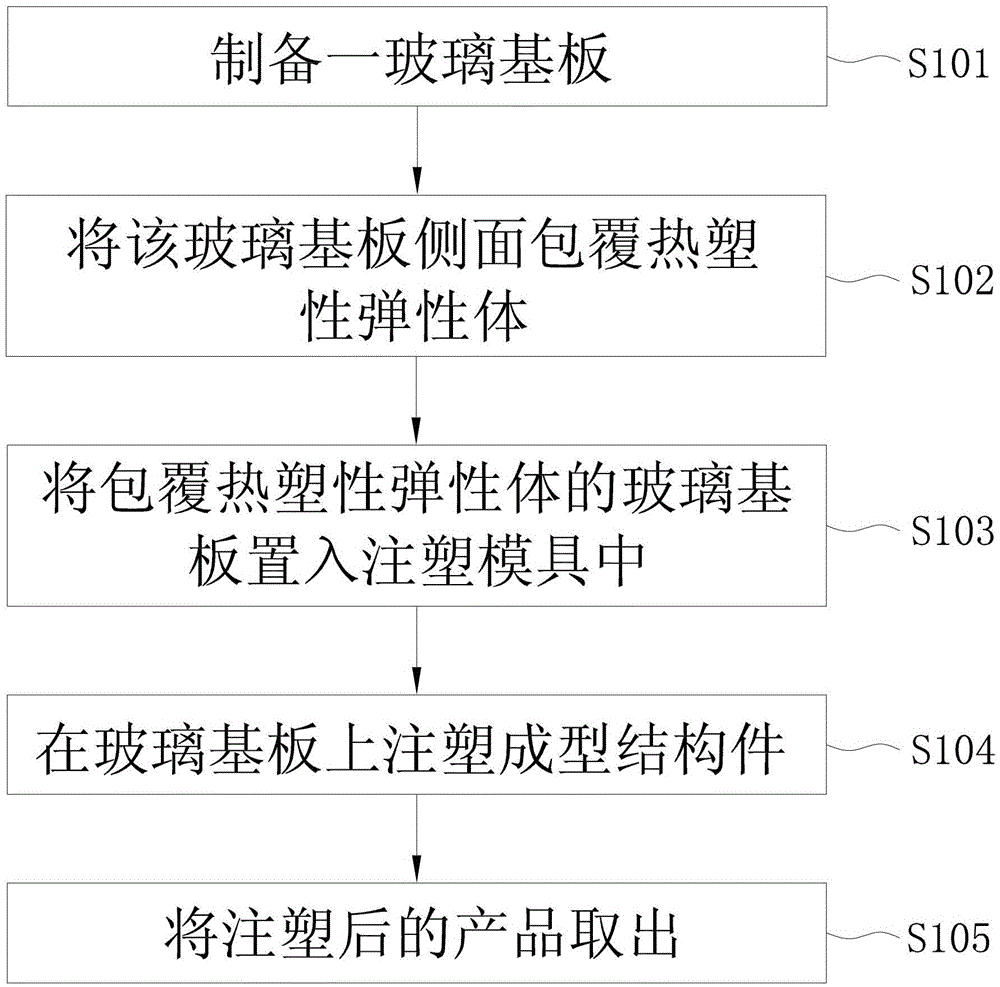

[0026] see figure 1 and figure 2 As shown, in this embodiment, the injection molding method of inserting glass into a mold of the present invention includes the following steps:

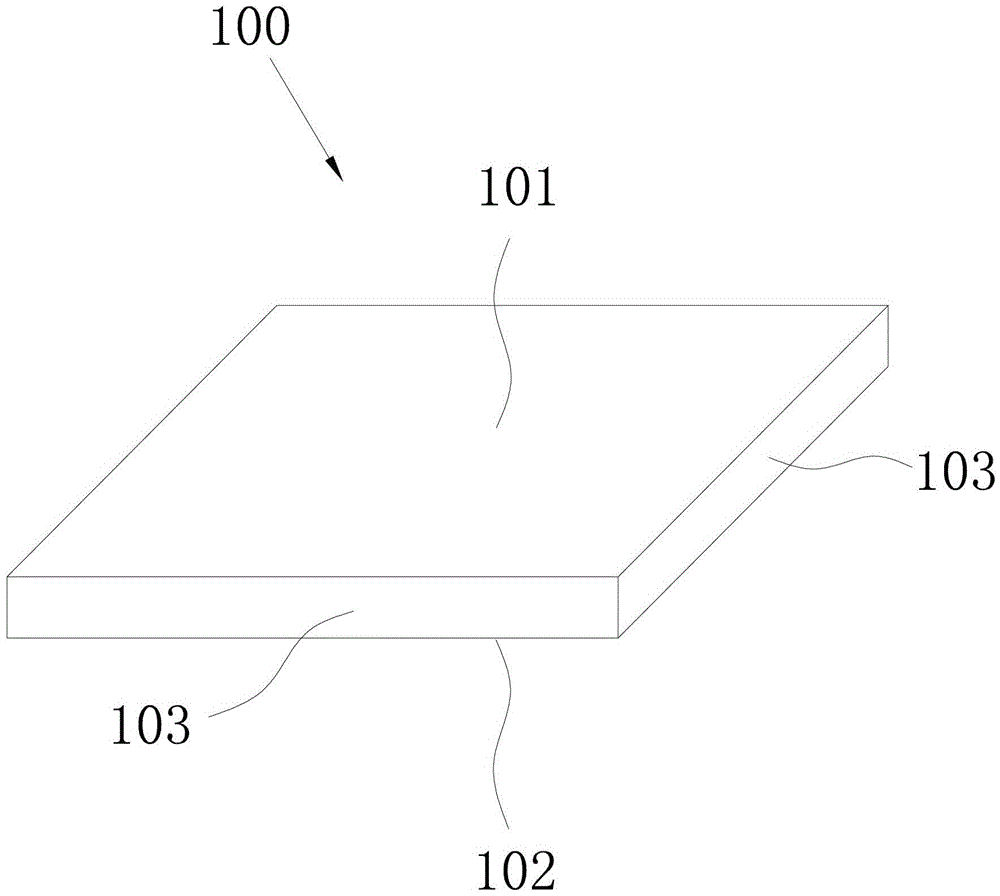

[0027] Step S101: prepare a glass substrate 100, the glass substrate 100 has a bottom surface 102, a top surface 101 and four sides 103 connecting the bottom surface 102 and the top surface 101, the glass substrate 100 is used in electronic products and can be used as an electronic product touch surface, or other structural parts of electronic products.

[0028] Step S102: Cover the side surface 103 of the glass substrate 100 with a thermoplastic elastomer frame. The body is pasted on the side surface 103 of the glass substrate 100, so that the glass substrate 100 is combined with the thermoplastic elastomer.

[0029] Step S103: Put the above-mentioned glass substrate 100 coated with a thermoplastic elastomer frame into an injection mold.

[0030] Step S104: heating up the injection mold; then i...

Embodiment 2

[0033] In this embodiment, the injection molding method of inserting glass into a mold of the present invention includes the following steps:

[0034] Step S201: prepare a glass substrate 100, the glass substrate 100 has a bottom surface 102, a top surface 101 and four sides 103 connecting the bottom surface 102 and the top surface 101, the glass substrate 100 is used in electronic products and can be used as an electronic product touch surface, or other structural parts of electronic products.

[0035] Step S202: Wrap the side surface 103 of the glass substrate 100 with a thermoplastic elastomer frame. In this embodiment, the method of covering the thermoplastic elastomer frame is: apply glue on the side 103 of the glass substrate 100 or partially apply glue on the bottom surface 102, and then put the glass substrate 100 into a monochrome injection mold; The mold is heated and pressurized; then liquid thermoplastic elastomer is injected into the mold cavity of the injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com