Integrated farming sewage treatment apparatus

A technology for breeding sewage and treatment equipment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, animal husbandry wastewater treatment, etc. problems, to achieve the effect of convenient detection and maintenance, saving waste, and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

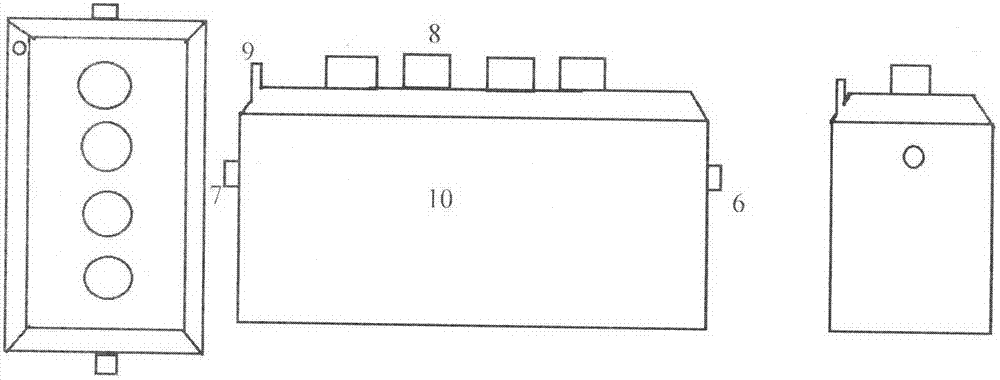

[0012] in the attached Figure 1 In the process, the aquaculture biogas slurry waste liquid that has been filtered in the early stage flows into the integrated aquaculture sewage treatment machine (10) from the sewage water inlet (6), and undergoes multiple biochemical reaction treatments, sedimentation filtration, disinfection and other processes in the integrated machine, and the sewage treatment The clean water reaching the standard is discharged from the clean water outlet (7), wherein the sedimented and filtered biochemical reaction sludge is stored in the sludge pool (4), and the sludge therein is cleaned regularly through the sludge extraction port (9).

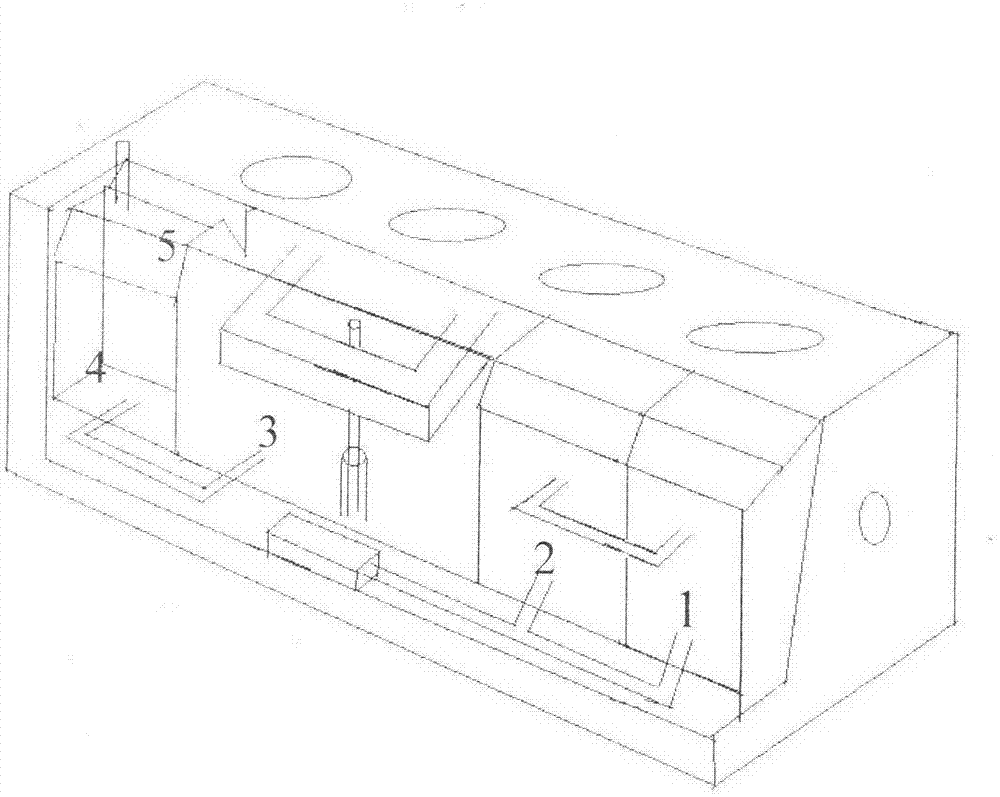

[0013] in the attached Figure II In the process, the sewage enters the primary oxidation tank (1), which contains high-efficiency biological composite fillers to fully take place the hydrolytic acidification reaction to decompose the large particles of organic matter in the sewage. After fully reacting, the primary ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com