Method and device for continuous and uniform metering and feeding of viscoplastic sludge

A viscoplastic and sludge technology, applied in the field of continuous and uniform metering and feeding of viscoplastic sludge, can solve the problems of prolonging the mixing time, difficulty in mixing uniformly, and inability to uniformly discharge the sludge, so as to reduce the occupied area and achieve the degree of automation High and shorten the effect of mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] What is described below in conjunction with the accompanying drawings is only a preferred embodiment of the feeding method for continuous and uniform metering of viscoplastic sludge described in the present invention. Several improvements and deformations all belong to the protection of the present invention.

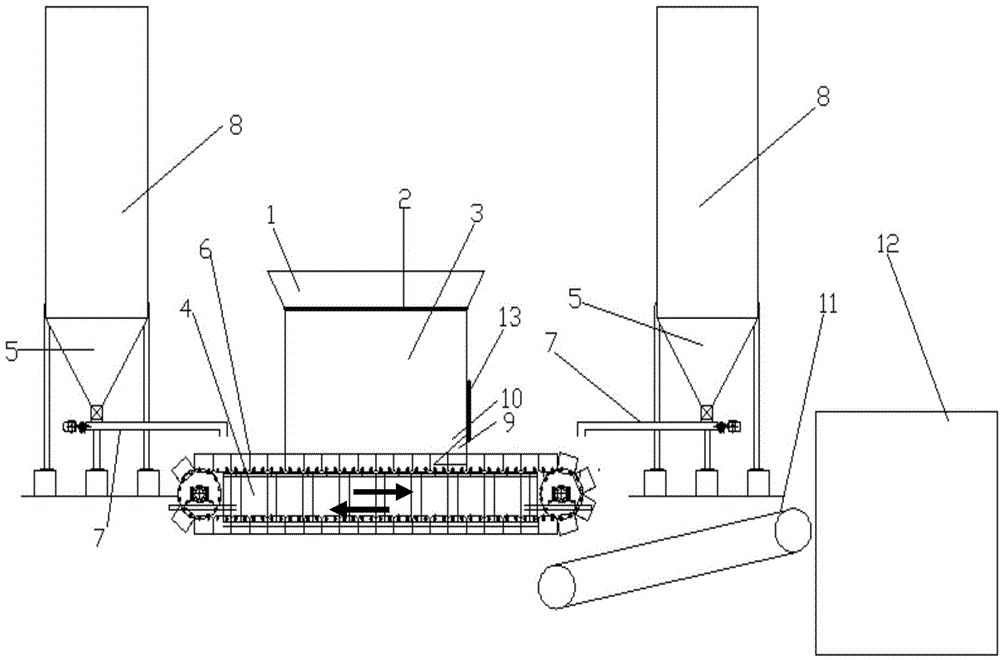

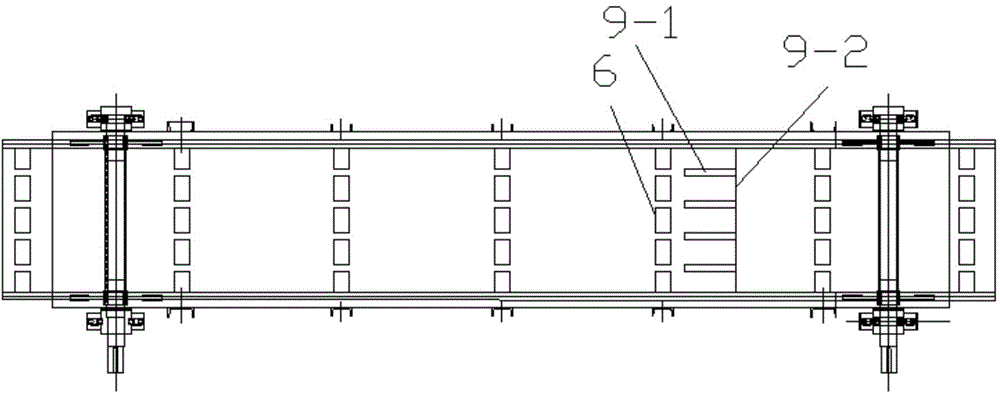

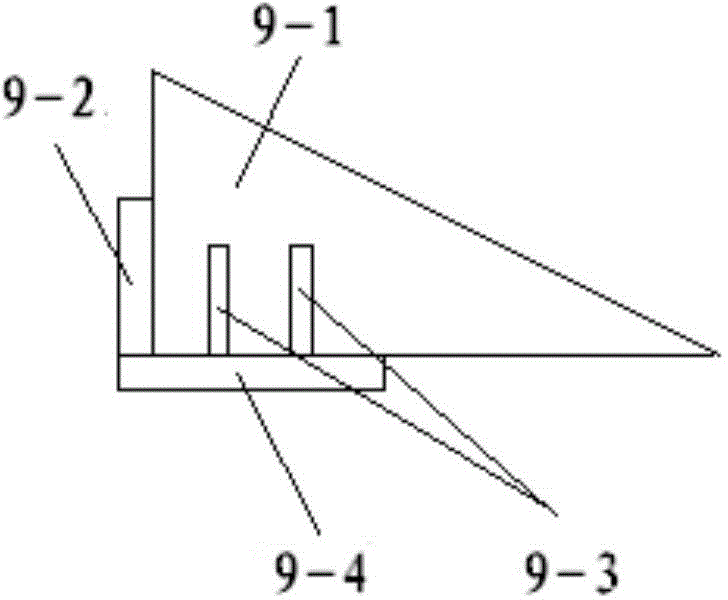

[0031] Such as figure 1 As shown, the device of the present invention includes a blanking system, two sets of anti-sticking devices, and a belt conveyor 11. Two sets of anti-sticking devices are respectively installed at the front end and the discharge end of the blanking system, and the anti-sticking device installed at the front end of the blanking system is discharged. The mouth is facing the mud plate 6 of the blanking system, and the anti-sticking device discharge port installed at the discharge end of the blanking system is facing the mud plate 6 and the conveyor belt of the belt conveyor 11 of the blanking system.

[0032] Such as figure 1 As shown, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com