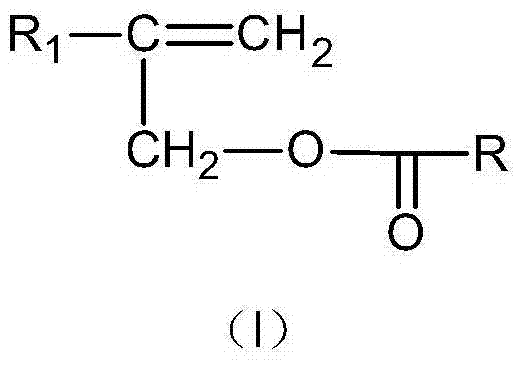

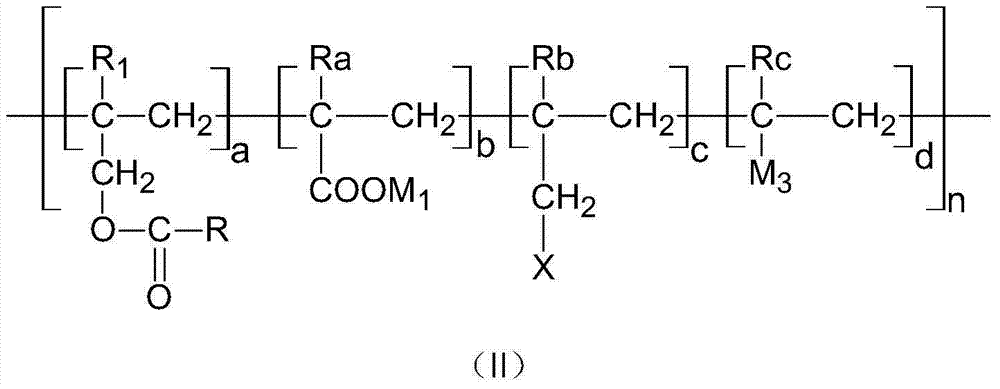

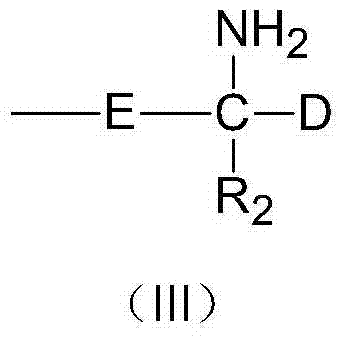

Amino acid esterification product modified polycarboxylic superplasticizer and preparation method thereof

A technology of amino acid ester and water reducing agent, applied in the field of high performance concrete water reducing agent, can solve the problems of long transportation time and large demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Add 100g of aspartic acid and 130.8g of allyl alcohol (molar ratio 1:3) into the reaction vessel, feed HCl gas at 20°C, stir mechanically for 1h, heat to reflux for 30min, and distill under reduced pressure to remove the reaction product. Water and excess propenyl alcohol, the resulting product is the esterification product of aspartic acid.

[0081] In the reaction vessel, sequentially add 300g of modified polyether (TPEG) with a molecular weight of 1000, 200g of purified water and 15.5g of aspartic acid esterification product, raise the temperature to 50-70°C under mechanical stirring, and add the initiator sodium persulfate 4.5g, after stirring evenly, start to drop 90g of acrylic acid and 40g of a 10wt% solution of chain transfer agent thioglycolic acid (mass ratio of chain transfer agent to initiator is about 1:1), dropwise for 60-120min, dropwise Continue to react after 120-180min, stop heating.

[0082] Add NaOH solution with a mass fraction of 30% to adjust the...

Embodiment 2

[0084] Add 100g of phenylalanine and 105g of allyl alcohol (molar ratio 1:3) into the reaction vessel, feed HCl gas at 20°C, stir mechanically for 1h, heat and reflux for 30-60min, and distill under reduced pressure to remove the reaction product Water and excess propenyl alcohol, the resulting product is the esterification product of phenylalanine.

[0085] In the reaction vessel, sequentially add 300g of modified polyether (TPEG) with a molecular weight of 1000, 200g of purified water and 16.5g of aspartic acid esterification product, raise the temperature to 50-70°C under the condition of mechanical stirring, and add the initiator sodium persulfate 4.5g, after stirring evenly, start to drop 90g of acrylic acid and 40g of a 10wt% solution of chain transfer agent thioglycolic acid (mass ratio of chain transfer agent to initiator is about 1:1), dropwise for 60-120min, dropwise Continue to react after 120-180min, stop heating.

[0086] Add NaOH solution with a mass fraction of...

Embodiment 3

[0088] Add 100g of aspartic acid and 130.8g of allyl alcohol (molar ratio 1:3) into the reaction vessel, feed HCl gas at 20°C, stir mechanically for 1h, heat to reflux for 30min, and distill under reduced pressure to remove the reaction product. Water and excess propenyl alcohol, the resulting product is the esterification product of aspartic acid.

[0089] Add 300 g of allyl polyethylene glycol with a molecular weight of 2400 and 50 g of sodium methallyl sulfonate into the reaction vessel, add 200 g of water and 16.5 g of aspartic acid esterification product, and heat up to 50-70 °C under mechanical stirring. ℃, add 4.5g of initiator hydrogen peroxide, and start to dropwise add 90g of acrylic acid and 40g of 10wt% solution of chain transfer agent mercaptoacetic acid after stirring evenly (the mass ratio of chain transfer agent to initiator is about 1:1), drop The time is 60-120min, continue to react for 120-180min after the dropwise addition, and stop heating.

[0090] Add N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com