A laser-enhanced electrodeposition rapid prototyping device and method

A forming processing and laser strengthening technology, applied in the direction of electroforming, electrolysis process, etc., can solve the problems of adding templates for preparation and installation, metal parts with complex structures, and low precision of formed parts, so as to improve quality and performance, and highly selectivity , The effect of accelerating the charge transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

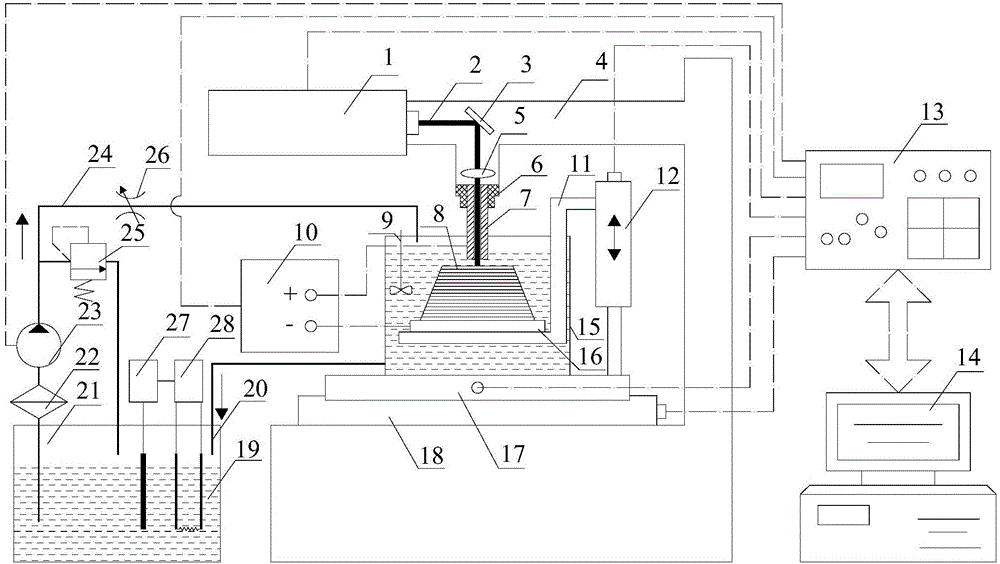

[0024] Such as figure 1 As shown, this embodiment includes a laser generating mechanism, an anode seat 6, an anode 7, a cathode, a power supply 10, a three-dimensional mobile platform, a working platform 11, a deposition tank 15, a constant temperature liquid storage mechanism and a controller 13; the anode 7 and the laser The generating mechanism is connected, the anode 7 is located in the anode seat 6, the deposition tank 15 is provided with an electrodeposition solution 19, the cathode is a deposition substrate 16, and the deposition substrate 16 is immersed in the electrodeposition solution 19 in the deposition tank 15, and the power supply 10 is respectively Connect the cathode and the anode 7; the three-dimensional mobile platform includes an X-axis mobile platform 17, a Y-axis mobile platform 18 and a Z-axis mobile platform 12, and one end of the working platform 11 is connected to the cathode, and the other end is connected to the Z-axis mobile platform 12, The X-axis mo...

Embodiment 2

[0037] This embodiment adopts laser-enhanced electrodeposition to rapidly form Cu metal parts on the graphite surface, and the specific steps are as follows:

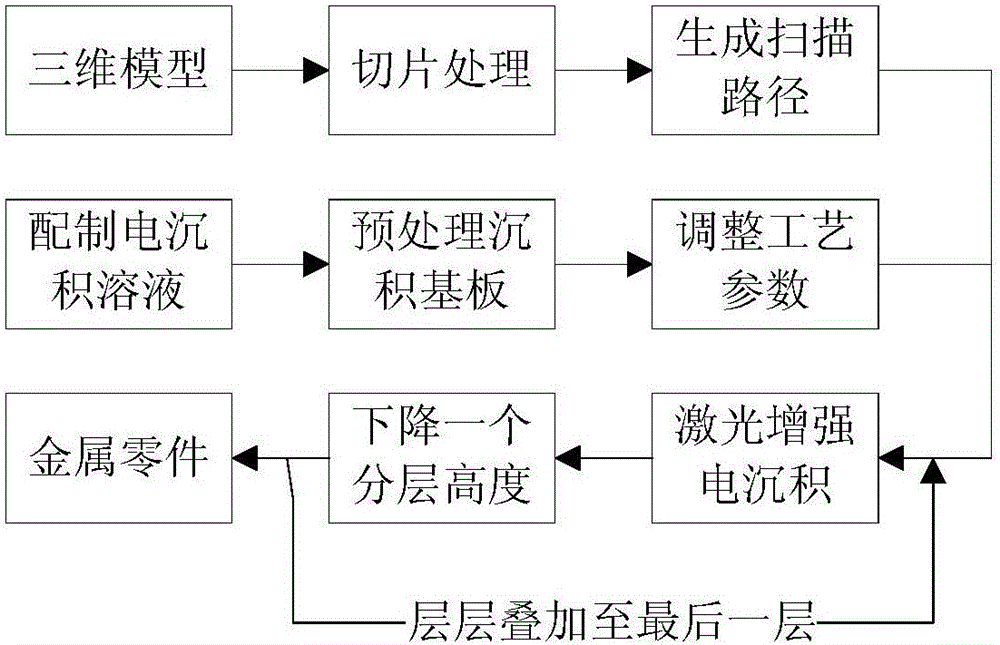

[0038] (1) First, the computer 14 performs three-dimensional modeling of the metal parts to be processed, and generates STL files, and then divides the three-dimensional solid model in STL format into many small thin layers through layering software, and generates according to the two-dimensional data of each thin layer section scan path;

[0039] (2) Preparation of electrodeposition solution 19: copper sulfate (CuSO 4 ·5H 2 O) 50g·L -1 , sulfuric acid (H 2 SO 4 ) 50g·L -1 , wetting agent (C 12 h 25 SO 4 Na) 0.1~0.2g·L -1 , brightener (saccharin) 1~3g·L -1 , the pH value is kept at 4±0.1, and the temperature of the electrodeposition solution 19 is kept at about 45°C; the graphite deposition substrate 16 is subjected to surface treatments such as polishing, degreasing, passivation, washing, and drying;

[0040...

Embodiment 3

[0043] This embodiment adopts laser-strengthened electrodeposition to rapidly form Ni-Mn alloy parts on the surface of 1Cr18Ni9Ti stainless steel, and the specific steps are as follows:

[0044] (1) First, the computer 14 performs three-dimensional modeling of the metal parts to be processed, and generates STL files, and then divides the three-dimensional solid model in STL format into many small thin layers through layering software, and generates according to the two-dimensional data of each thin layer section scan path;

[0045] (2) Preparation of electrodeposition solution 19: nickel sulfamate (Ni(NH 2 SO 3 ) 2 4H 2 O) 430~600g·L -1 , manganese sulfamate (Mn(NH 2 SO 3 ) 2 4H 2 O) 12~28g·L -1 , nickel chloride (NiCl 2 ·6H 2 O) 15~25g·L -1 , boric acid (H 3 BO 3 ) 30~35g·L -1 , wetting agent (C 12 h 25 SO 4 Na) 0.1~0.2g·L -1 , brightener (saccharin) 1~3g·L -1 , the pH value is kept at 4±0.1, and the temperature of the electrodeposition solution 19 is kept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com