Building ceramic sheet honeycomb ground system and its construction method

A technology of architectural ceramics and ground systems, which is applied in the direction of buildings, building structures, floors, etc. It can solve the problems of external precipitation of steam and water phases, easy generation of gaps in stone slabs, and easy aging of sealants, achieving high processing accuracy and convenient and fast construction , The effect of strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

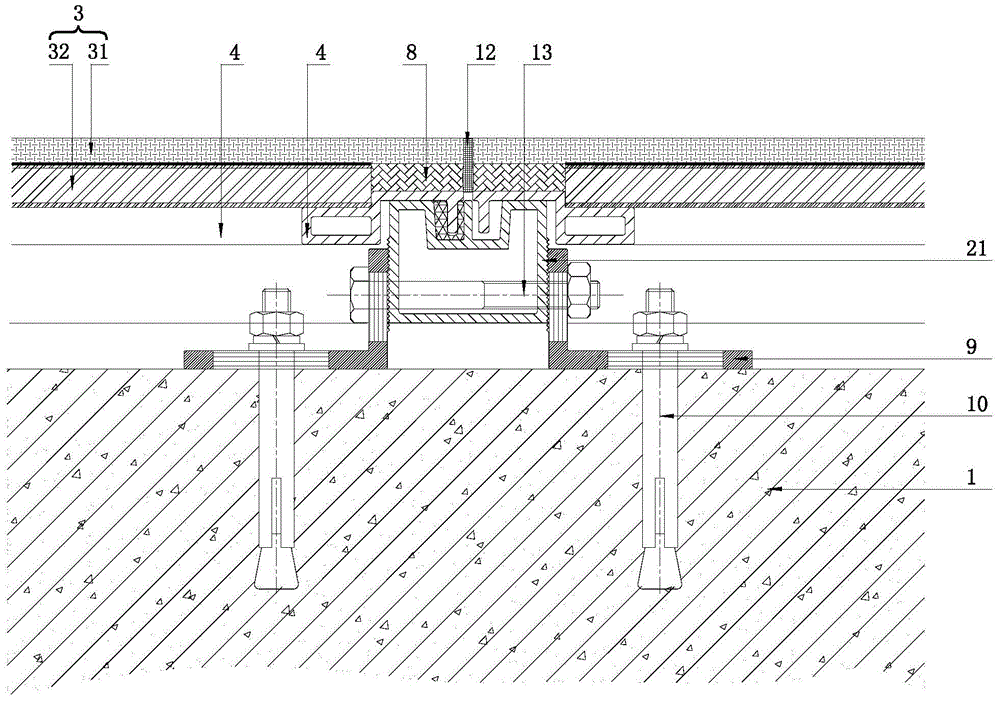

[0045] Such as Figure 1 to Figure 2 As shown, the building ceramic sheet honeycomb ground system includes ground 1, keel 2, ceramic aluminum honeycomb composite board 3 and back frame 4;

[0046] The ground 1 is a reinforced concrete floor;

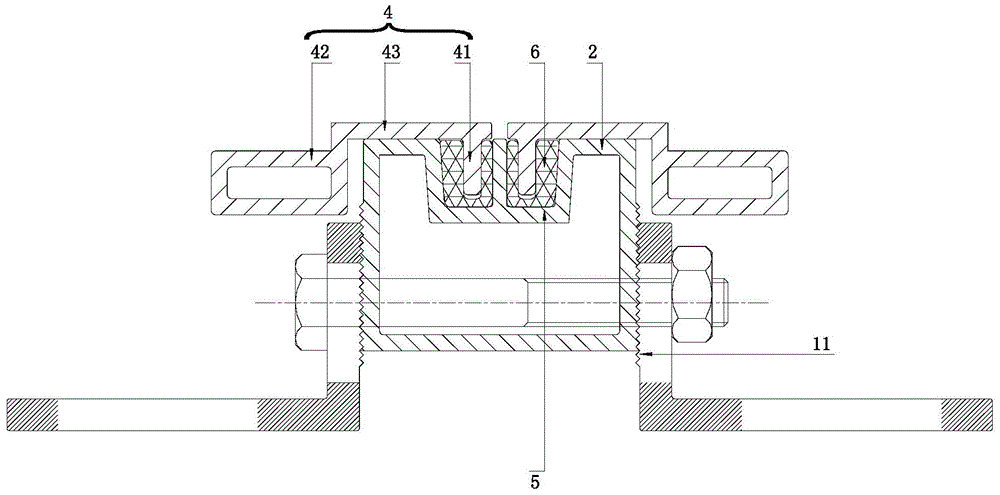

[0047] The keel 2 is a profile, installed vertically and horizontally on the ground 1 to form a grid shape, and a grid composed of the keel 2 is installed with a piece of the ceramic aluminum honeycomb composite panel 3, and the upper surface of the keel 2 is provided with a card. slot 5;

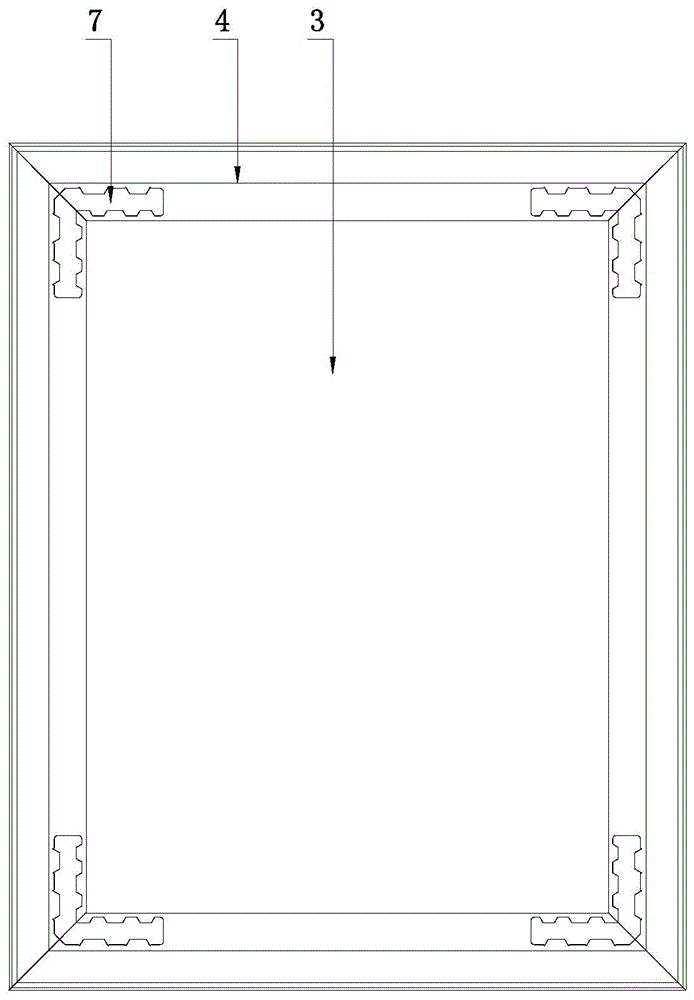

[0048] The ceramic aluminum honeycomb composite panel 3 is square, including a ceramic sheet 31 and an aluminum honeycomb panel 32, and the aluminum honeycomb panel 32 is pasted on the back of the ceramic sheet 31;

[0049] The back frame 4 is a plane square frame, inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com