Whole bathroom floor

A bathroom and ground technology, applied in the direction of architecture, building structure, etc., can solve the problems of high cost, heavy weight of the module, and the impact of the surrounding environment, achieve a harmonious decoration effect, and improve the effect of user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

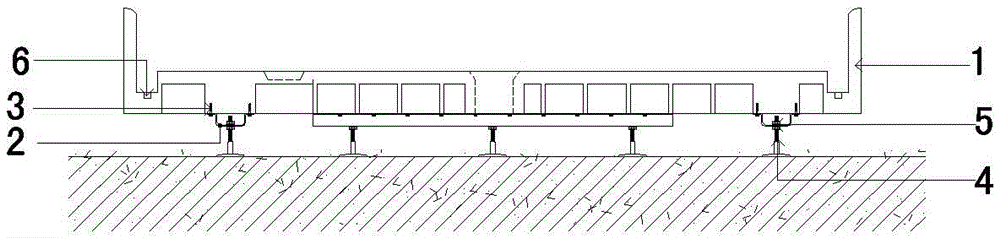

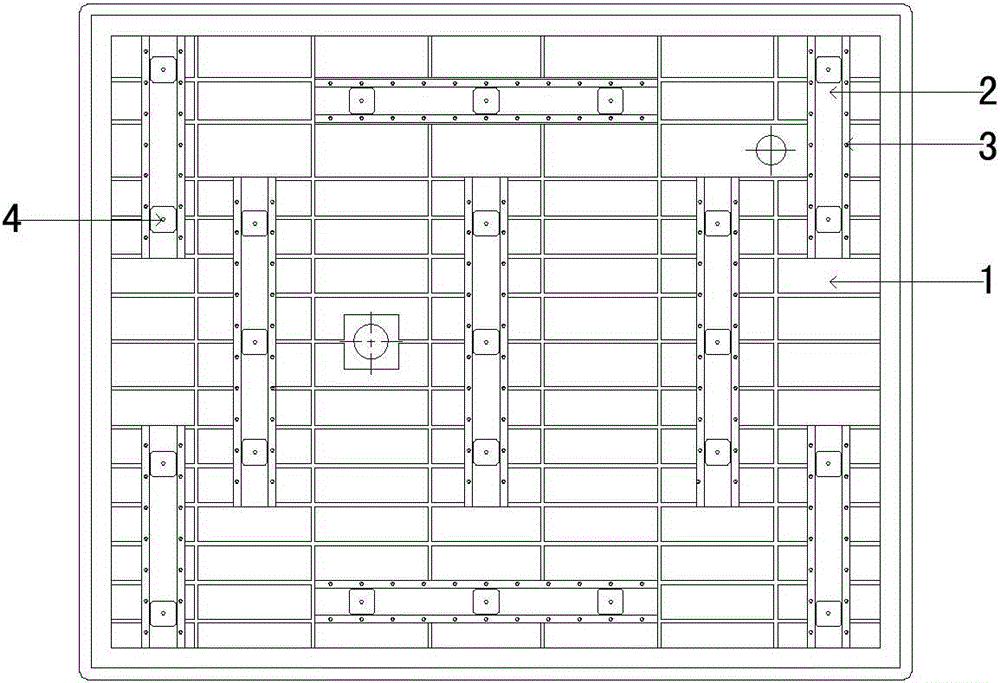

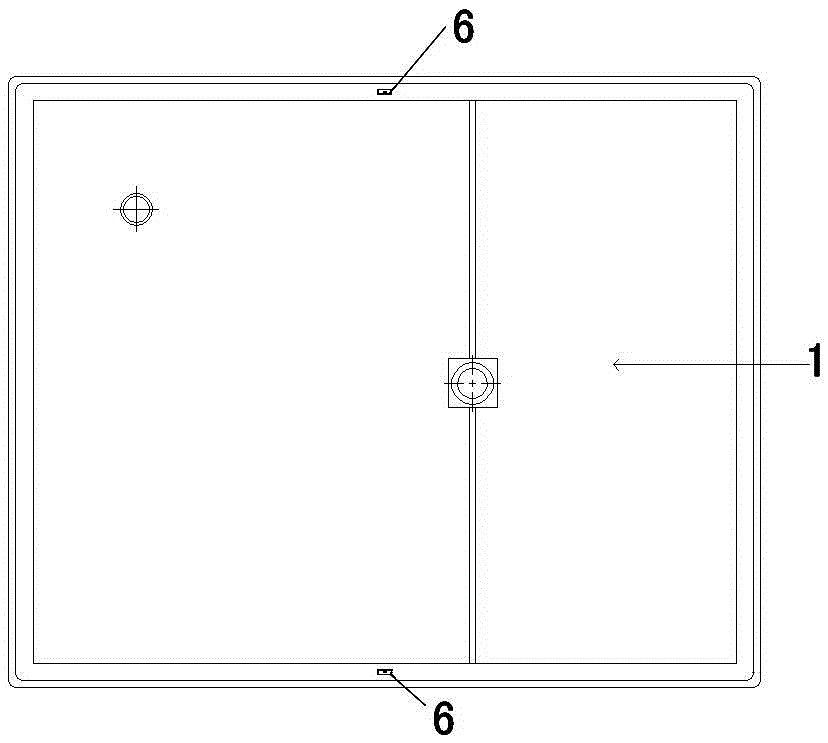

[0025] Example: such as figure 1 , Figure 4 As shown, a whole bathroom floor, which includes a bathroom floor module 1, a customized special-shaped metal strip 2, and a customized base 4.

[0026] Customized special-shaped metal strips 2 are installed on the back of the bathroom floor module 1 through bolts 3. Multiple customized special-shaped metal strips 2 are distributed on the back of the bathroom floor module 1 according to the requirement of uniform force, and the customized special-shaped metal strips 2 are installed below There are a plurality of customized bases 4 evenly distributed, the height of the customized bases 4 is 120mm-160mm, the upper end of the customized bases 4 is provided with a screw rod, and the customized bases 4 are installed under the customized special-shaped metal bar 2 through the cooperation of the screw rods, nuts and gaskets 5 . The bathroom floor module 1 is provided with a vial 6 for checking whether the bathroom floor module 1 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com