Three-dimensional water-absorbing and water-locking hand towel and preparation method thereof

A paper towel and water-locking technology, which is applied in chemical instruments and methods, household appliances, machining/deformation, etc., can solve the problems that it is difficult to achieve rapid and large water absorption, increase the production cost of paper towels, and reduce the water absorption of paper towels. , to achieve the effect of improving the speed of water absorption and the range of diffusion, fewer layers, and reducing the use of paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Mix 20g of starch, 10g of polyethylene glycol, 5g of chitosan, 1.0g of a leveling agent, and 60g of water evenly, heat at 50°C for 25min under stirring, and obtain a binder after the reaction is completed.

Embodiment 2

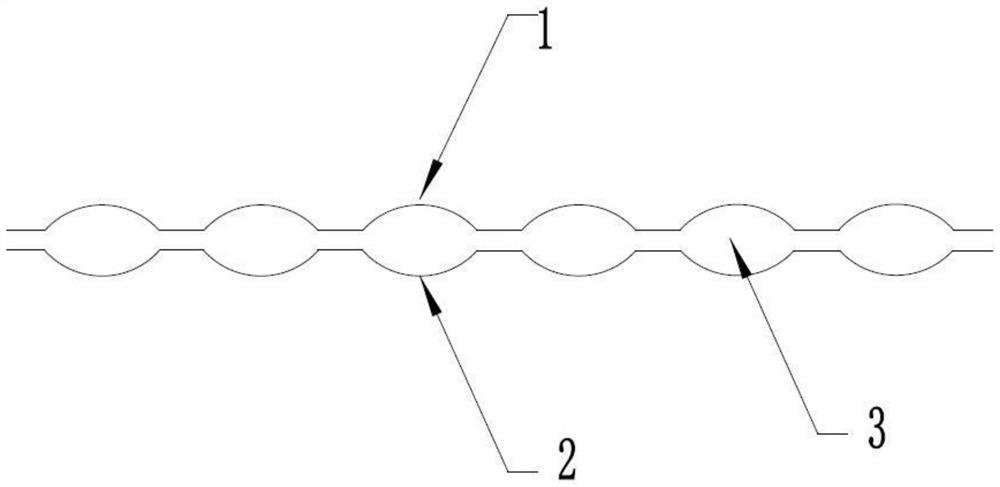

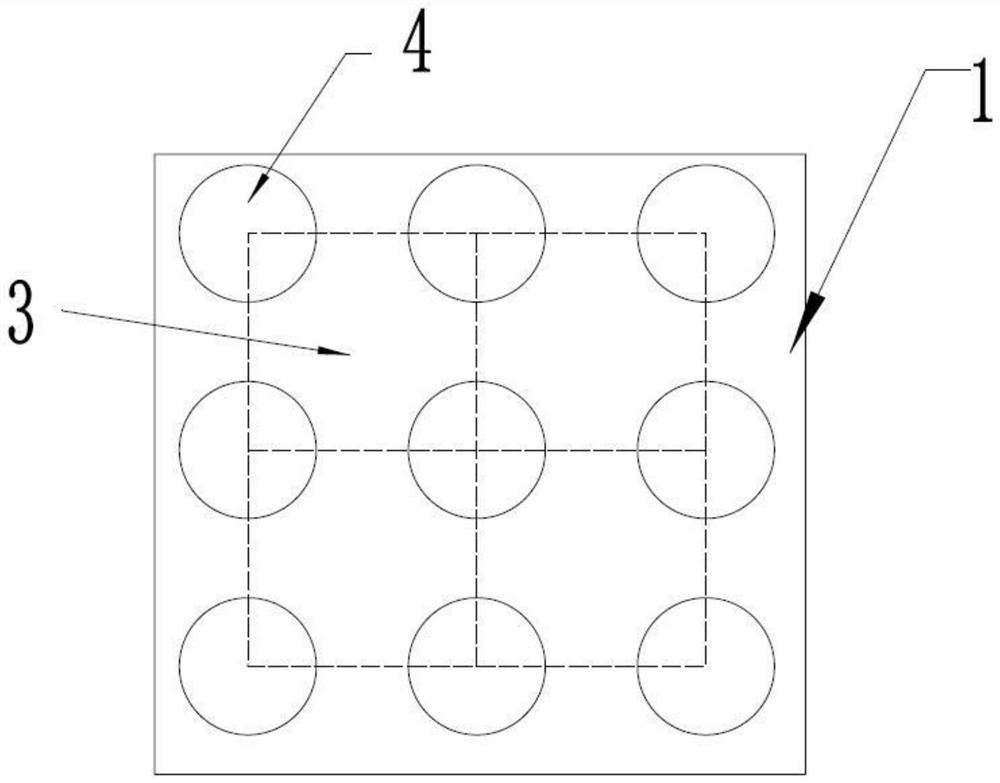

[0047] Using a gluing compound embossing machine (FH-2850 purchased from Dongguan Zhihong Machinery Manufacturing Co., Ltd.), two 1m 2 The long-fiber wood pulp paper is placed up and down to obtain an upper surface paper and a lower surface paper, embossing is downward on the upper surface of the upper surface paper, and embossing is upward on the lower surface of the lower surface paper. 324900 embossing points, that is, raised bonding points, are evenly distributed on each long-fiber virgin pulp paper.

[0048]The binder prepared in Example 1 is evenly coated on each raised bonding point on the long-fiber virgin pulp paper, and the upper surface paper and the lower surface paper are oppositely bonded together, and the binder consumption is 2g / m 2 . Rewinding, cut into paper towels with specifications of 215mm*205mm, such as image 3 shown.

[0049] In the present invention, although the water content of the adhesive is relatively large, the bonding point is very small, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com