Heat-dissipation type wear-resistant brake pad

A brake pad, heat dissipation technology, applied in the direction of friction linings, brake types, brake components, etc., can solve the problem that straight grooves cannot achieve multi-working conditions brake heat dissipation effect, affect the performance stability of friction blocks, and cannot be uniform in friction blocks. Heat dissipation and other problems, to achieve the effect of good heat dissipation and cooling effect, good heat dissipation effect, and stable performance of brake pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

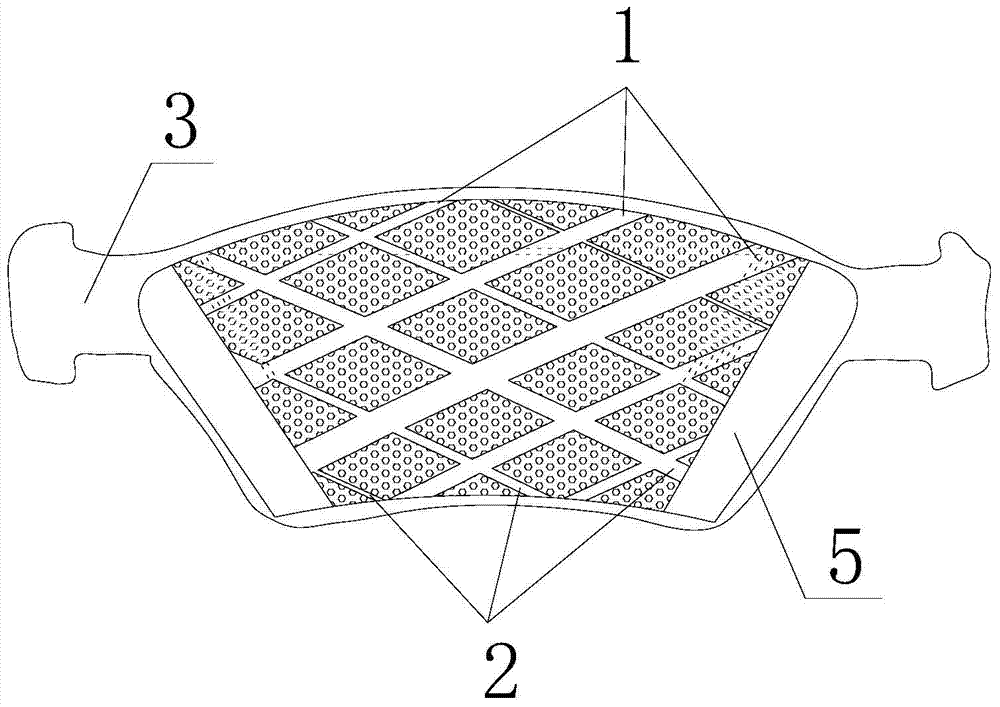

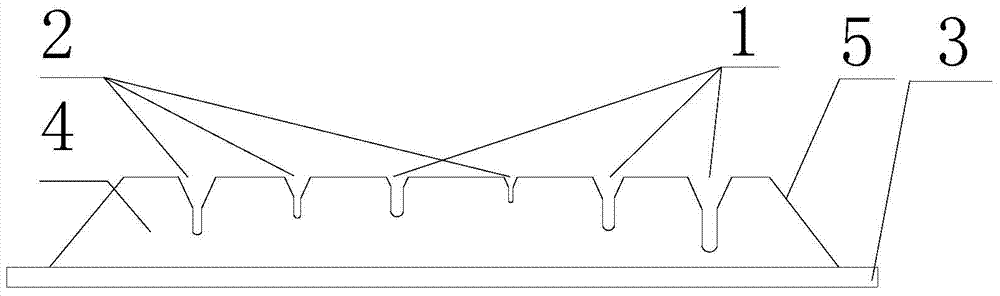

[0013] Such as figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of a heat-dissipating wear-resistant brake pad proposed by the present invention; figure 2 It is a side view of a heat dissipation wear-resistant brake pad proposed by the present invention.

[0014] refer to figure 1 and figure 2 , a heat-dissipating wear-resistant brake pad proposed by the present invention, including a metal sheet 3 and a friction block 4, the metal sheet 3 and the friction block 4 are bonded together as a whole, and the two sides of the friction block 4 are arranged There is a buffer slope 5, and the friction surface of the friction block 4 facing the brake disc is provided with micro pits; the friction surface of the friction block 4 facing the brake disc is provided with a first arc-shaped groove group 1 and a second arc-shaped groove Grooving group 2, the arc-shaped protruding direction of the arc-shaped slots in the first arc-shaped slotting group 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com